I’ve spent decades watching manufacturing evolve, and from what I’ve seen, the next decade will be defined not by small improvements but by sweeping transformation driven by AI and automation. As Chief Technology and Digital Officer at Associated Metal Forming Technologies, I see a future that is already unfolding around us. The future is now, and here’s how AI will reshape our industry. Some of use will choose to lead, others will follow. I choose to lead.

Across the sector, disruption is arriving in waves. Autonomous systems are beginning to take on tasks that once demanded constant human oversight, from precision inspection to predictive quality control. Supply chains are shifting from fixed and reactive to fluid and adaptive, responding instantly to shocks and disruptions. The age of mass customization is no longer theoretical; factories must now pivot between unique product variants without sacrificing efficiency. In this environment, the most profound shift is cultural as much as technical. Manufacturers that own and integrate their data will separate themselves from those still working in silos. What companies should be addressing is not whether to automate, but how to use AI to amplify human expertise rather than replace it.

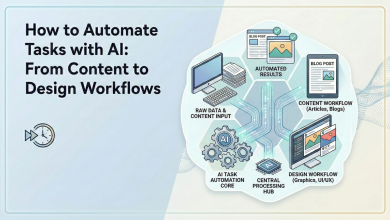

The opportunity in front of us is not just about reducing cost. When deployed thoughtfully, AI and automation act as a force multiplier that turns experience and insight into precision and speed. Predictive maintenance will evolve into continuous health monitoring that prevents downtime before it happens. Smart scheduling and digital flow optimization will shorten changeovers and reduce waste. AI-powered vision systems will enhance quality assurance by identifying defects earlier and with greater accuracy. Even simulation tools, guided by generative models, are allowing engineers to explore design and process variations faster than ever before. In short, AI makes it possible for our people to focus on innovation instead of repetition.

After attending Dreamforce 2025 this past October, several lessons resonated with me that apply directly to manufacturing. The first is that data governance is no longer optional; every AI model and autonomous agent depends on clean, consistent, and auditable data. Without a strong data foundation, even the most advanced algorithms will drift or misfire. The second is that AI coupled with analytics matter far more than flashy dashboards – the term is called conversational analytics. Companies should be pursuing context, accuracy, and truth over vanity metrics. Another key takeaway was the rise of “agentic” systems, autonomous digital agents, are beginning to transform how businesses operate. Agentic marketing and agentic manufacturing are two sides of the same evolution, and the convergence between the two will reshape how we design, sell, and deliver products. Salesforce’s push toward unified data layers and governed AI agents shows where things are heading: connected systems that act in context and across functions, with humans still guiding the process.

From why perspective, the most successful companies will be those that start small but think big. Piloting AI agents within specific departments, such as quality control or scheduling, creates an early blueprint for scaling across the factory floor. These pilots reveal the importance of governance, interoperability, and the human role in oversight. Before deploying autonomous systems at scale, companies must focus on building strong data foundations, establishing clear accountability, and ensuring that people are equipped to supervise and refine the algorithms that assist them. Investing in upskilling is just as important as investing in automation itself, because the real power of AI comes from teams who know how to interpret, challenge, and improve it.

This is a call to arms for manufacturing leaders. We can no longer afford to wait for change to reach us; we must drive it ourselves. The companies that will thrive are the ones that treat AI not as a replacement for people, but as a partner in performance. They will build systems that learn in real time, factories that adapt instantly, and organizations that grow smarter with every data point. The opportunity is here, the tools are ready, and the differentiator will be courage.

The future is now. Let us be the ones to steer it.