When making purchase decisions about warehouse equipment, I like to start with the boring stuff.

Before even glancing at a vendor catalog, I dig into data and do a ton of research on the way a particular piece of equipment may affect the flow of the warehouse, as well as the potential constraints it could uncover.

Different pieces of warehouse material handling equipment fit together into different warehouses in various ways, and it helps to level-set early so you’re not comparing apples to forklifts. The goal is to build a warehouse that moves product predictably on your best days and during peak chaos.

Know Your Demand Profile

Most warehouses break down because they optimize for normal demand, and then November shows up like a prank. That’s a huge mistake. The question isn’t simply what volume you can handle, but what volume you’re able to sustain predictably at peak, with a mix of orders.

If you want to get a feel for demand pressure in the wider market, the U.S. Census Bureau’s quarterly e-commerce report for Q3 2025 put U.S. retail e-commerce sales at about $310.3B, and noted e-commerce was roughly 16.4% of total sales that quarter.

You don’t need to be an e-commerce brand to feel the ripple effects of that. Faster expectations usually show up as more single-line orders, smaller cartons, tighter cutoffs, and more variability, which is exactly the kind of stuff that punishes warehouses built only for pallet-in/pallet-out simplicity.

Start With the Flow

Before you pick equipment, think about how your inventory flows through the warehouse. Where does the product enter, pause, and change state? A warehouse is basically a sequence of handoffs, and the right equipment is the stuff that makes those handoffs less painful.

If you skip this step, you’ll tend to buy equipment that looks efficient in isolation, like fast conveyors, while ignoring the fact that your bottleneck is actually at receiving, or in replenishment, or in the fact that your pickers spend half their shift walking around hunting for the next task.

A simple mental trick is to picture your busiest hour and visualize where people tend to bunch up, where pallets block aisles, where scanning slows down, and where exceptions pile up. Equipment should relieve that pressure, not just make one area feel futuristic.

Remember that Safety is a Design Requirement

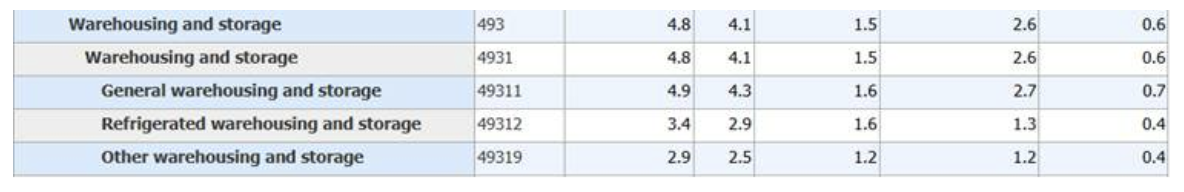

One sobering data point that keeps everyone grounded is the BLS incidence-rate table for 2024, which reports warehousing and storage at 4.8 total recordable cases per 100 full-time workers, with 4.1 cases involving days away from work, job restriction, or transfer.

These very real sprains, strains, collisions, falls, and near-misses are often tied to layout, congestion, and equipment/pedestrian interaction.

OSHA’s warehousing guidance also calls out ergonomic risk factors like heavy lifting, awkward postures, pushing/pulling loads, and repetitive tasks. These are all things that the right equipment choices can reduce, and the wrong ones can accidentally intensify.

So, when you’re choosing equipment, think like a traffic engineer and separate pedestrians from vehicles where you can. Reduce blind corners and make staging predictable. Most importantly, use equipment that fits the work instead of forcing people to make it work with awkward lifts and constant twisting.

People, Training, and Turnover Need to Be Part of the Decision

Even with great equipment, your warehouse runs on humans, so your staffing reality should influence what you buy. If you have high turnover, equipment that requires deep operator skill or constant fine-tuning may frustrate you. If you have a stable, experienced team, you can take on more complexity and get more upside from it.

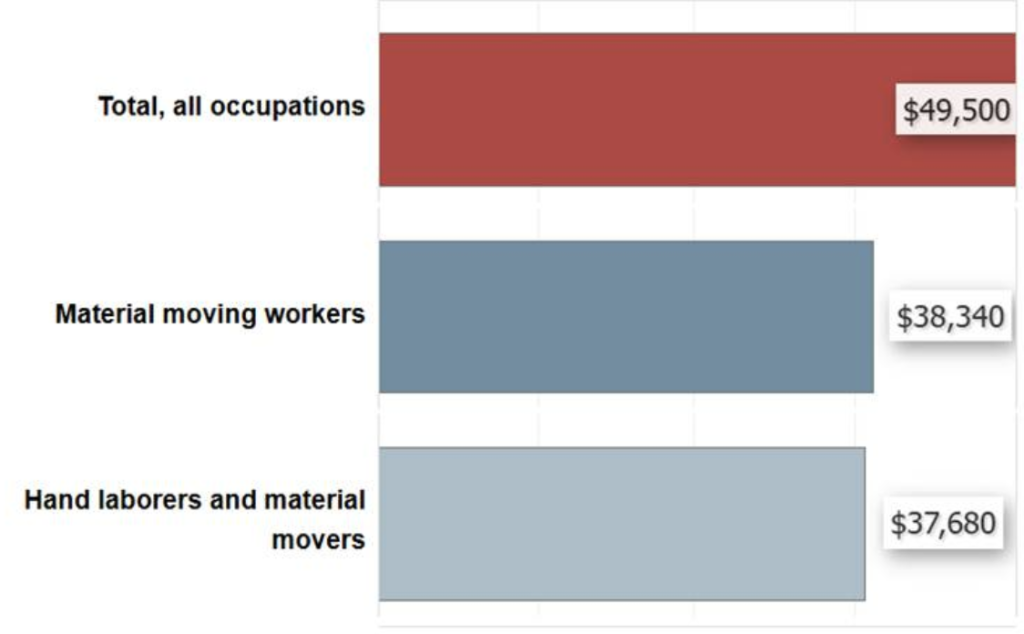

For context on the scale of labor in this space, the BLS Occupational Outlook Handbook notes about 6.95 million jobs (2024) for hand laborers and material movers. Median pay is only around $37,680 (May 2024), even though these roles can have some of the highest injury and illness rates due to physical demands.

[Source: BLS]

Design so that normal work is safe, trainable, and repeatable. The right equipment shouldn’t require heroics to hit baseline performance.

Data Integration Is a Force Multiplier

Equipment doesn’t operate in a vacuum. Scanners, labels, location logic, replenishment triggers, slotting rules, and task interleaving all determine whether your equipment feels like a smooth system or a collection of machines that constantly argue with each other.

When equipment and systems are aligned, you get fewer mis-picks and late shipments, which is how warehouse decisions translate into better customer experiences without anyone having to do dramatic overtime to save the day.

If you’re upgrading equipment, it’s worth asking what data the new gear generates, what decisions it can automate, and whether your current systems can actually use that information.

Future-Proof Without Chasing Hype

A lot of teams get stuck in limbo between doing nothing and buying into the whole robot-overlord shtick. However, the middle path is usually the best, as is often the case. That means making choices that keep options open.

Design aisles and power drops with expansion in mind, while standardizing load types where possible. Leave room for staging, returns, and rework, because those always grow, and favor modular equipment and processes you can scale.

It’s fine to keep an eye on 2026 tech predictions, but treat them like interesting, directionally useful forecasts, not a reason to remodel your entire life.

Bottom Line

The right warehouse equipment is the stuff that makes your operation feel boring in the best way. When orders flow and exceptions are handled, people don’t have to sprint around fixing avoidable problems.

To get there, start with flow and demand, match equipment to your inventory language, reduce touches, design for safety, and make sure your data and processes can support whatever you buy.

If you do that, you’ll soon end up with a warehouse that behaves like a system. And when you have that, the sky’s the limit.