Introduction

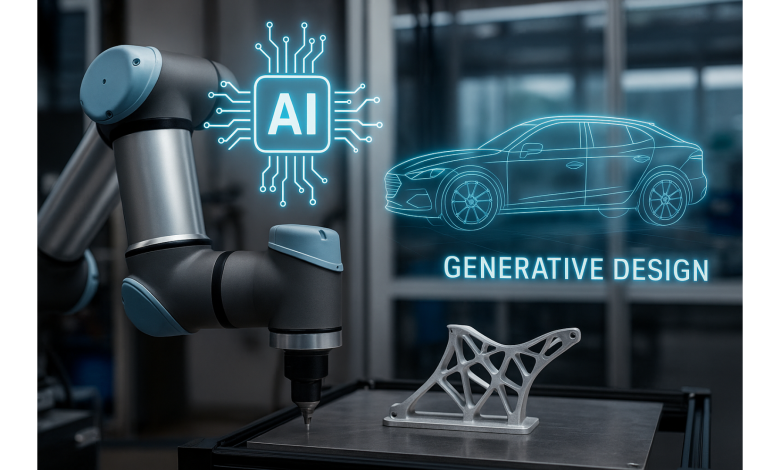

The evolution from additive to automated manufacturing represents the shift in how vehicles are designed and manufactured in the 21st century. Additive manufacturing, also known as 3D printing, is a process where materials are deposited layer by layer to form complex structures. Artificial intelligence (AI), on the other hand, refers to systems that are capable of learning from data and optimizing their performance autonomously. Together, these two technologies are revolutionizing the automotive industry by merging creativity with computation.

The automotive sector, valued at over $2.9 trillion globally, is seeing an accelerated shift toward digital manufacturing. According to McKinsey, AI-driven product design can reduce development cycles by up to 30%, while additive manufacturing lowers prototyping costs by nearly 50%. This synergy is not just about producing parts faster; it’s about creating more innovative, lighter, and more sustainable vehicles. In this article, you’ll learn how AI is transforming the design process, how 3D printing empowers innovation, and how their integration defines the future of automotive manufacturing.

How Is AI Transforming the Automotive Design Process?

AI is transforming automotive design by turning what once took months into processes that can be iterated in days. Artificial intelligence is a computational system capable of learning from massive datasets and applying logic to generate optimized design solutions. In vehicle development, AI is now used to simulate aerodynamics, predict structural weaknesses, and even suggest alternative materials for better performance.

Car manufacturers like BMW and Ford already use AI to refine vehicle body shapes through generative design software. This approach enables designers to define goals, such as weight reduction or crash resistance, while AI explores thousands of combinations to find the optimal outcome. The result is a car that’s not just stylish but scientifically optimized for both efficiency and safety.

By reducing trial and error and enhancing simulation accuracy, AI is redefining creative freedom in vehicle design while accelerating time-to-market and reducing waste.

What Role Does Additive Manufacturing Play in Vehicle Innovation?

Additive manufacturing is a production process that constructs objects layer by layer using digital models. In automotive applications, this technology bridges the gap between imagination and production, enabling engineers to quickly prototype, test, and iterate components. The ability to produce complex geometries allows carmakers to develop lightweight structures without sacrificing strength.

In practice, additive manufacturing reduces design constraints and supports the shift toward electric and autonomous vehicles. The ability to rapidly produce intricate cooling channels, brackets, and housings is invaluable for next-generation energy-efficient designs.

Below are the main stages of additive manufacturing in automotive:

- Concept modeling: Creating visual representations of vehicle parts for design validation.

- Prototyping: Printing parts for mechanical testing and aerodynamic assessment.

- Pre-production validation: Ensuring the printed components meet performance criteria.

- Full-scale part integration: Transitioning validated designs into production-ready components.

Many manufacturers now rely on industrial 3D printing solutions to achieve repeatable, high-precision results across R&D and production environments.

Understanding the Core Technologies Behind 3D Printing and AI Integration

Both 3D printing and AI operate on digital data frameworks that can communicate with each other seamlessly. Additive manufacturing generates precise digital-to-physical conversions, while AI interprets performance data to refine those designs. This integration forms a closed-loop manufacturing system, where machines learn from every build and adjust parameters autonomously to achieve continuous improvement.

These core technologies rely on data analytics, simulation software, and automated control systems, enabling higher levels of manufacturing intelligence. AI not only interprets performance but also predicts errors before they occur, making the process both efficient and sustainable.

Generative Design

Generative design is a computational process where AI explores all possible design permutations to meet specific performance requirements. It takes inputs such as load constraints, material options, and manufacturing methods, and outputs multiple optimized models. In vehicle design, it enables reduced material use and improved performance by allowing software design to be based on data rather than relying solely on human intuition.

The designer’s role shifts from creator to curator, selecting the best solution among those generated by the AI.

How Machine Learning Optimizes 3D Printing Parameters

Machine learning optimizes 3D printing by analyzing feedback from previous builds to fine-tune process variables, such as temperature, layer height, and extrusion speed. This ensures consistent print quality even in large-scale production.

Below are four optimization factors:

- Speed: Balancing build time with material integrity.

- Accuracy: Minimizing dimensional deviation across builds.

- Material waste: Reducing excess use through predictive calibration.

- Print consistency: Maintaining identical outputs across multiple runs.

Through continuous learning, machine learning converts every print job into an opportunity for refinement.

What Is Predictive Maintenance in Additive Manufacturing?

Predictive maintenance is the process of using AI-driven analytics to foresee and prevent equipment failures before they happen. In additive manufacturing, it analyzes sensor data such as vibration, temperature, and print quality to detect early signs of malfunction. By scheduling maintenance proactively, manufacturers can reduce downtime and extend the lifespan of their machines.

This is particularly valuable for high-volume automotive production, where every hour of uptime matters.

How Do AI and 3D Printing Work Together in Vehicle Design?

AI and 3D printing work together as partners in a continuous feedback loop. Artificial intelligence interprets simulation data, predicts mechanical performance, and informs how the next prototype should be printed. Additive manufacturing, in turn, provides real-world validation that feeds back into the AI model for further optimization.

Together, they bridge the virtual design and physical production processes in real-time. CAD software and digital twins allow engineers to simulate vehicle parts under stress before printing, while AI automatically adjusts geometry for improved results.

Stages of AI-Enhanced Additive Workflow

There are five main stages involved in integrating AI with additive design and manufacturing:

- Concept generation with AI-based modeling.

- Structural simulation and stress prediction.

- Material selection and topology optimization.

- 3D printing and sensor-based monitoring.

- Post-print inspection and AI-driven adjustment.

This loop ensures that every prototype becomes smarter than the previous one.

What Are the Main Applications of AI-Driven 3D Printing in Automotive Manufacturing?

The applications of AI-driven 3D printing extend far beyond prototyping. They are now shaping how vehicles are built, tested, and customized.

Here are five of the most impactful applications:

- Lightweight chassis and suspension components for improved efficiency.

- Custom interior features and ergonomic designs tailored to users.

- Battery housings and cooling structures for electric vehicles.

- Aerodynamic optimization for body panels and spoilers.

- Tooling and jigs that accelerate factory workflows.

These use cases demonstrate how AI and 3D printing are not just reshaping design but redefining production efficiency and sustainability across automotive manufacturing.

Advantages of Combining AI and Additive Manufacturing for Vehicle Design

The synergy between AI and additive manufacturing delivers multiple benefits for automotive innovation. By combining data intelligence with digital fabrication, manufacturers achieve unprecedented speed, flexibility, and environmental efficiency.

There are six main advantages of this integration:

- Accelerates prototyping cycles and design iteration.

- Reduces material and energy waste through optimization.

- Enhances structural strength while minimizing weight.

- Enables real-time feedback and adaptive manufacturing.

- Improves predictive maintenance and quality assurance.

- Supports long-term sustainability and reduced emissions.

The ability to iterate instantly and produce precisely what’s needed is changing the economics of car design forever.

Limitations and Challenges of AI in Additive Automotive Design

Despite the breakthroughs, AI integration in additive automotive design still faces hurdles that must be addressed for large-scale adoption.

There are five main disadvantages of implementing these systems:

- Requires significant computational resources for data processing.

- Lacks industry-wide software standardization.

- Faces ongoing material compatibility and print reproducibility issues.

- Demands high upfront investment in infrastructure and talent.

- Suffers from a shortage of cross-disciplinary experts in AI and materials science.

These challenges underscore the importance of collaboration between AI engineers and manufacturing specialists in advancing the field of AI.

How Does AI-Enhanced Additive Manufacturing Compare to Traditional Automotive Production?

AI-enhanced additive manufacturing offers faster design flexibility and customization compared to traditional subtractive and assembly-line methods. Traditional manufacturing remains superior in terms of volume and cost per part, but additive systems excel in efficiency for low- to medium-production runs and complex geometries.

Below is a simple comparison overview:

FactorAI + Additive Traditional Manufacturing

Design Flexibility Extremely high Moderate

Production Speed: Fast for low volume, faster for mass production

Material Waste Minimal High

Customization: Fully customizable, Limited

Cost per Unit: Higher initially, Lower at scale

Hybrid models that merge both approaches are increasingly becoming the new standard, ensuring agility and scalability in future manufacturing plants.

How to Integrate AI and 3D Printing into an Automotive Workflow

Integrating AI and 3D printing into existing automotive workflows involves both digital and operational transformation. Companies must assess their data infrastructure, production readiness, and workforce capabilities to ensure optimal performance.

There are four main steps involved in this process:

- Evaluate digital readiness and CAD data structures.

- Train AI models using existing design and production data.

- Incorporate sensor-based feedback loops for adaptive printing.

- Connect post-processing and quality assurance data into continuous AI learning.

Industrial systems such as Advanced Motion Controls’ intelligent servo drives play a vital role in synchronizing robotic arms, printheads, and conveyors for seamless automated control. Together with high-precision 3D printers, they establish the foundation of a smart, autonomous production environment.

What Does the Future Hold for AI and Additive Manufacturing in Automotive Design?

The future of AI and additive manufacturing in automotive design lies in complete digital continuity. Vehicles will soon be designed, tested, and built entirely within interconnected virtual ecosystems. Generative AI will assist designers from concept sketches to full-scale production models, while additive manufacturing will bring these visions to life in record time.

As electric and autonomous vehicles become mainstream, AI will optimize aerodynamics, thermal systems, and material use for sustainability. Combined with self-learning robots and cloud-based collaboration, this future signals a shift toward fully automated, energy-efficient vehicle production systems.

Conclusion

The convergence of AI and additive manufacturing marks a turning point in how cars are conceived, tested, and produced. By merging data-driven intelligence with design freedom, this partnership enables automakers to innovate more quickly and effectively. The benefits, from rapid prototyping to predictive optimization, are reshaping the entire value chain.

As the line between digital design and physical manufacturing continues to blur, the future of vehicle design will be defined not by what machines can make, but by how intelligently they can think and create together.