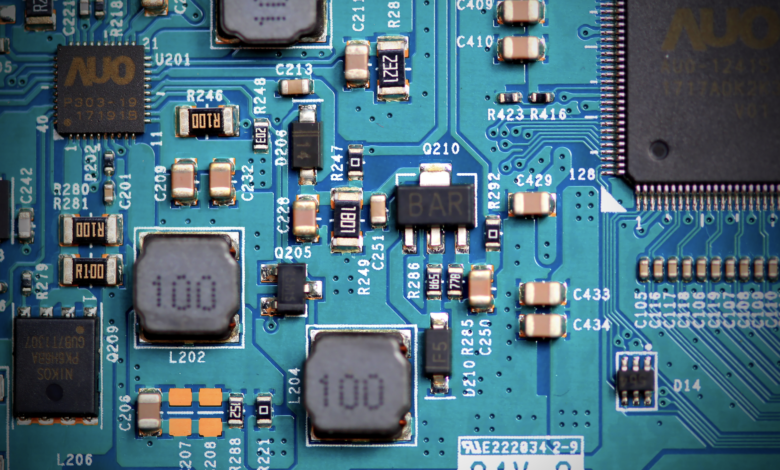

The semiconductor market has experienced unprecedented growth in recent years, underpinning almost every electronic planet. Demand for semiconductors is set to increase significantly, driven by the development of communications infrastructure. Over the past decade the UK’s semiconductor revenue increased by 95% and these trends are set to continue with the global market expected to reach almost $818bn by 2027. However, the inadequacies between supply and demand are having a negative impact on several semiconductor-dependent sectors, including the computer and automotive industries.

As the shortage of semiconductors continues, governments and tech companies are looking to increase production. For example, Intel has announced that they will spend around £80bn over the next decade along the entire semiconductor value chain – from research and development to manufacturing to state-of-the art packaging technologies. The company is expanding its manufacturing facilities in Leixlip, Ireland, for new process technologies and enlarged foundry services, bringing its total investment there to more than €30bn. Intel also plans to invest in Germany, France and Poland. By expanding production, manufacturers are able to reduce export costs, but also to reassure suppliers who use these chips.

The UK is facing calls to reduce its dependance on Chinese imports, which poses challenges in the event of supply difficulties or geopolitical tensions. To explore how the nation’s chip design start-ups and testing facilities can grow, the UK government recently commissioned a research project to look into growth opportunities, as well to bring together industry, customers and government to address shared challenges.

Similarly, the US and EU have already begun working on securing microchip independence with major investments into silicon and chip plants. For example, the EU’s European Chips Act and President Joe Biden’s CHIPS and Science Act were both passed last year to bolster the regions’ competitiveness and resilience in semiconductor technologies. According to the global industry association SEMI’s World Fab Forecast, 17 factories will be built in the EMEA region by 2024.

Five core considerations

Governments are ramping up their support of semiconductors – but what else can be done to unlock the full potential of the industry and ensure a reliable supply? There are five key issues and innovations that countries and companies need to consider in order to help to ensure the industry’s digital sovereignty.

1. Attracting and fostering talent

Alongside these governmental projects, there is a need to create a vast and qualified workforce to run semiconductor facilities and enhance innovation in the industry. Technology courses and retraining programs have been offered in Ireland, for instance, to provide employees with the necessary skills required for jobs in the latest electronics fields. These initiatives have motivated foreign companies like Qualcomm, to enlarge operations in the country – in fact, the company created a €78mn R&D center for ASIC research that is bringing on board hundreds of microelectronics engineers. They will work hand in hand with key Irish governmental institutes, like the IPIC and the Tyndall National institute, who also seek to attract and create a new generation of talent in the semiconductor sector.

2. Sustainability at the heart

Semiconductor companies should be looking to reduce the carbon footprint of IT systems, in line with global green transition priorities. According to Harvard researchers, the environmental impact of semiconductor manufacturing remains high in terms of energy and water consumption, but also in terms of waste generation. Organisations will therefore turn to less polluting practices, such as renewable energy, to reduce their emissions and keep countries on track to meet the UN’s 250 net zero goal.

3. Artificial Intelligence (AI) adoption

AI integration will also impact the sector. In order to produce advanced semiconductors, manufacturers will explore the best ways to develop chips suitable for AI models, which can process large amounts of data and enhance the performance of deployed tools. This combination will be particularly beneficial for the automotive industry, where connected cars are becoming increasingly important.

4. Layering chiplets

To enhance their competitiveness in the market, companies will benefit from interconnecting several small chips, also known as chiplets. These technologies – which can also significantly reduce manufacturing costs – will increase processor performance and allow different layers of functionality to be added.

5. Integrating 5G and 6G

The ability to connect large numbers of devices to 5G and 6G networks will be a major challenge for manufacturers in 2023. As the world becomes more digital, whether at the enterprise or smart city level, production of 5G and 6G semiconductors will increase to enable hyperconnectivity in networks. In other words, it will enable a higher level of data exchange, memory and storage between devices. This in turn can create new requirements and enhance the reliability of the global digital environment.

The future is collaborative

Collaboration and partnerships between government, research organisations and industry leaders are key to foster growth in the semiconductor sector. With countries and companies around the globe setting goals to increase production, intensify innovation and strengthen their competitiveness, the way forward is clear: industry cooperation.