The construction industry faces a problem that won’t be solved by incremental improvements or the latest project management software. With global infrastructure demands projected to exceed $106 trillion by 2040 and a persistent skilled labor shortage affecting nearly every developed nation, the industry needs more than efficiency gains—it needs a fundamental reimagining of how we build.

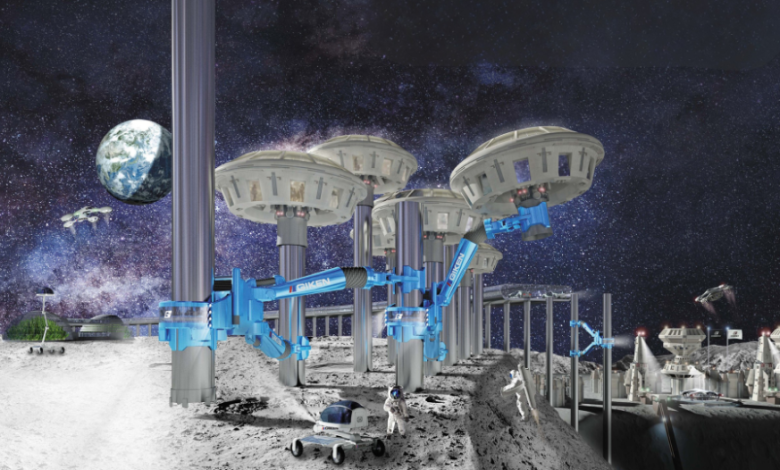

While most construction technology discussions focus on marginal productivity improvements or digitizing paperwork, a more radical transformation is already underway. The convergence of artificial intelligence, IoT sensors, and autonomous systems isn’t just making construction faster or cheaper—it’s making it possible in places where humans simply can’t work. Building on the moon might sound like science fiction, but the thought behind the process is forcing us to solve problems that will reshape how we build everywhere.

The Accessibility Problem No One Talks About

Construction automation conversations typically center on large contractors and massive infrastructure projects. But the real barrier isn’t technological capability—it’s accessibility. Most “smart construction” solutions require specialized equipment, extensive training, and substantial upfront investment that puts them out of reach for the vast majority of builders.

This accessibility gap means that while a handful of megaprojects benefit from cutting-edge technology, the overwhelming majority of construction work continues using methods that would be recognizable to builders from decades ago. The labor shortage compounds this problem: you can’t scale an industry that depends entirely on specialized human expertise that takes years to develop.

What’s needed is construction intelligence that works with existing equipment rather than requiring complete replacement. When AI can guide standard machinery through complex tasks, and IoT sensors can provide the environmental awareness that skilled operators normally provide, automation becomes accessible to organizations of any size. This isn’t about replacing craftspeople—it’s about augmenting their capabilities and extending their reach.

Learning From Extreme Environments

The push to develop lunar construction capabilities is accelerating innovations that solve earthbound problems. When you’re designing systems to operate in zero gravity with no atmosphere and communication delays measured in seconds, you’re forced to rethink every assumption about how construction works.

Consider the challenges: machinery must operate autonomously without constant human oversight. Systems need to sense and respond to environmental conditions without the benefit of human intuition. Equipment must coordinate complex tasks without verbal communication. Every action requires precision because mistakes in extreme environments can be catastrophic.

But these constraints aren’t creating new technology—they’re forcing us to perfect what the industry has needed for quite some time. Systems navigating disaster zones and underwater sites today become moon-capable through refinement, not reinvention. Solve for Earth’s most extreme conditions, and space readiness follows.

Digital Twins: Testing Before Building

One of the most practical innovations emerging from extreme environment construction is the digital twin—a complete virtual replica of physical systems that enables risk-free experimentation. Before committing resources to actual construction, every aspect of a project can be simulated, tested, and optimized in digital space.

For lunar construction, digital twins are essential because you can’t send a repair crew if something goes wrong. But the same capability transforms earthbound construction by allowing builders to identify and solve problems before they manifest physically. This dramatically reduces costly errors, minimizes material waste, and ensures that automated systems perform as expected in real-world conditions.

Digital twins also democratize advanced construction techniques. A small contractor can virtually test complex automation sequences before deploying them on an actual site, gaining confidence without the risk of expensive mistakes. This levels the playing field between large organizations with extensive resources and smaller operators who need to get things right the first time.

Intelligence at the Edge

The key to accessible construction automation is intelligence that operates locally rather than depending on constant connectivity to distant servers. Edge computing—where AI processing happens on-site rather than in the cloud—is particularly crucial for both lunar and remote terrestrial construction.

This architecture enables machinery to make sophisticated decisions in real-time without communication delays. An autonomous excavator can analyze terrain and adjust its approach instantly. A pile-driving system can sense underground conditions and modify its operation accordingly. Robotic equipment can coordinate complex tasks through local mesh networks rather than routing everything through central servers.

Beyond enabling autonomous operation, edge intelligence addresses practical concerns about data security, network reliability, and bandwidth limitations.

Reimagining Human Roles

Autonomous construction doesn’t remove humans from the equation; rather, it redefines their role. Instead of performing repetitive on-site tasks, operators shift toward strategic oversight and higher-value problem-solving.

Skilled operators can supervise multiple autonomous systems simultaneously, intervening when situations require human judgment. Engineers can focus on optimization and innovation rather than routine monitoring. Safety specialists can ensure compliance without constantly exposing themselves to hazardous conditions.

This evolution addresses the labor shortage not by replacing workers but by enabling each person to accomplish more. A single experienced operator overseeing autonomous equipment can produce what previously required a full crew. This multiplication of human capability is how the industry can meet growing infrastructure demands despite workforce constraints.

The Infrastructure We Actually Need

While conversations about lunar bases capture imaginations, the real value of this technology is solving immediate terrestrial challenges. Aging infrastructure in developed nations needs replacement and upgrading, and developing regions require new construction to support economic growth. Meanwhile, climate change demands resilient infrastructure in previously uninhabitable areas and disaster response requires rapid construction capabilities in damaged zones.

Autonomous construction technology addresses all of these needs by making it possible to build faster, in more locations, with fewer specialized workers. The same systems being designed for extraterrestrial construction can rebuild after hurricanes, construct in remote regions, or work underwater on port facilities.

This isn’t about choosing between moon bases and earthly infrastructure—it’s recognizing that solving the extreme challenges of off-world construction produces solutions for problems we’re facing right now.

The Accessible Path Forward

The most important shift in autonomous construction is that it doesn’t require starting from scratch. Existing equipment can be upgraded with AI guidance and IoT sensors, turning standard machinery into intelligent systems without wholesale replacement. This layered approach lowers barriers to entry and puts advanced capabilities within reach for organizations of all sizes.

Small contractors can automate targeted tasks without massive capital outlay. Regional builders can deploy the same intelligence as global firms. Developing markets can bypass traditional constraints by adopting systems that reduce reliance on specialized expertise.

The future of construction won’t be defined by who buys the newest machines, but by who uses intelligence most effectively. Progress will come from augmentation, not replacement—and from access, not exclusivity. Autonomous construction is already changing how we build on Earth. The only question left is how fast we make it available to everyone.