Artificial intelligence now redefines operational efficiency within the manufacturing sector’s supply chain. Warehouses, once simple storage facilities, have now become dynamic hubs of predictive and automated activity. The integration of AI technologies presents a significant opportunity for leaders to enhance productivity.

These advanced systems optimize inventory management, improve order fulfillment accuracy, and create safer work environments. For executives, the question is not whether to adopt AI, but how to strategically implement it. This shift represents a fundamental change from reactive processes to proactive, data-driven operational control.

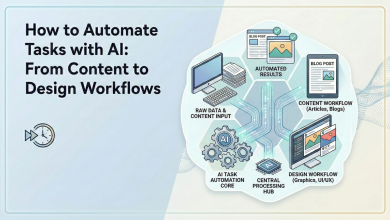

These warehouse AI upgrades for manufacturing companies show a path toward a more intelligent, responsive, and profitable business operation. These applications from autonomous robots to advanced analytics platforms will ensure you future-proof your business and remain on top of the competitive market.

Predictive Inventory Management Systems

AI-powered systems analyze historical data to forecast future inventory needs with remarkable precision. These platforms consider market trends, seasonal demand, and even promotional events for better stock levels. This foresight reduces overstock situations and costly stockouts that disrupt production schedules.

They allow for automated reorder points based on real-time consumption and lead time data. This ensures a continuous flow of materials without manual intervention or spreadsheet-based guesswork. Proactive inventory control directly supports just-in-time manufacturing models and enables maximum efficiency.

Autonomous Mobile Robots (AMRs)

Autonomous mobile robots navigate warehouse floors to transport goods without fixed paths or human operators. They use sensors and AI-based mapping to select the most efficient routes for their tasks. AMRs can retrieve raw materials or move finished products to outbound docks with complete autonomy.

These robots work alongside human employees to accelerate put-away and retrieval operations safely. This collaboration frees human workers from repetitive travel, so they can focus on complex tasks. The result is a substantial increase in throughput and a reduction of physical strain.

AI-Powered Quality Control Vision Systems

Advanced vision systems use AI algorithms to detect product defects with superhuman accuracy and speed. These cameras identify subtle imperfections, incorrect assemblies, or cosmetic flaws on the production line. This automated inspection process maintains high standards without slowing the flow of goods.

The system learns from new defect data to continuously improve its detection capabilities over time. It can flag items for removal or alert operators to potential issues upstream. This immediate feedback loop prevents widespread quality problems and reduces expensive rework or recalls.

Intelligent Robotic Sorting Solutions

Robotic arms equipped with AI can sort mixed items with incredible speed and precision. These systems identify products based on size, shape, barcode, or even visual appearance. They then route each item to its correct destination for packing or shipment.

This automation drastically reduces manual sorting errors that lead to incorrect customer orders. The technology handles high volumes of diverse products without fatigue or loss of focus. One of the main benefits of how agentic systems are transforming factories is the level of intelligence and adaptability offered in executing predefined tasks.

Voice-Directed Picking and Tasking

AI-driven voice systems provide audible instructions to warehouse staff through headsets and microphones. Workers receive clear commands for their next pick, which they confirm verbally. This hands-free approach allows them to focus entirely on the physical task without distraction.

The technology can operate in multiple languages and recognize various accents, supporting a diverse workforce. It streamlines the entire order fulfillment process, from picking items to confirming their placement. This innovation improves both the speed and the accuracy of manual warehouse activities.

AI-Enhanced Warehouse Management Systems (WMS)

Modern Warehouse Management Systems use AI to optimize every facet of warehouse operation. They suggest the best storage locations for incoming goods based on forecasted demand. The software also directs workers on the most efficient paths for picking and packing tasks.

Understanding what linear automation is will ensure you can see how these systems differ. They dynamically adjust operational plans in response to real-time events, such as rush orders. It represents a significant step forward for fulfillment centers that handle complex order profiles.

Predictive Maintenance for Warehouse Equipment

AI monitors the condition of critical warehouse equipment, such as conveyors, lifts, and sorters. It analyzes sensor data for vibrations, temperature, or performance anomalies to predict potential failures. This allows maintenance teams to schedule repairs before a breakdown disrupts the entire operation.

This proactive approach minimizes unplanned downtime, which is a major source of lost revenue. It also extends the operational life of expensive machinery through timely service interventions. Predictive maintenance turns equipment management from a reactive chore into a strategic operational advantage.

Dynamic Slotting and Storage Optimization

AI algorithms continuously analyze product velocity and order patterns to recommend optimal storage locations. Fast-moving items get placed in easily accessible areas to minimize travel time for pickers. Slower-moving products go to more remote locations within the warehouse.

This dynamic slotting strategy adapts to shifts in demand throughout the year. It ensures the warehouse layout remains efficient even as product popularity changes. Optimized slotting directly translates to faster order cycle times and improved labor productivity.

Automated Palletization and Depalletization

Robots with AI vision can build stable, optimized pallets from a stream of mixed cases. The system calculates the best stacking pattern based on case size, weight, and fragility. This automation creates denser, safer pallets for storage or transport without the need for human labor.

AI-powered robots can unload pallets and place items onto conveyor systems. They identify each box and handle it appropriately to begin the inbound sorting process. This technology addresses a physically demanding task, which reduces worker injuries and improves throughput.

AI for Route and Load Optimization

AI software plans the most efficient routes for forklifts and other vehicles inside the warehouse. It considers traffic patterns, task priorities, and vehicle locations to prevent congestion. This system reduces travel time and fuel consumption for the entire internal vehicle fleet.

The same platforms optimize the loading of goods onto outbound trucks. AI arranges pallets based on delivery stops, weight distribution, and destination requirements. Efficiently packed trucks maximize space utilization and ensure faster, more organized unloading procedures.

The integration of artificial intelligence into warehouse operations offers manufacturing companies a distinct competitive edge. These technologies are not distant concepts; they are practical tools available for implementation today. From predictive analytics that sharpen inventory control to autonomous robots that accelerate logistics, AI delivers measurable returns.

Leaders who embrace these upgrades will build more resilient, efficient, and intelligent supply chains. The journey toward an AI-driven warehouse is an investment in future productivity and market leadership.