Progress in the food and beverage industry isn’t confined to the kitchen alone. Artificial intelligence now enables context-aware, adaptive support systems for baristas and kitchen staff at the point of preparation. Current architectures combine supervised and unsupervised learning, real-time inference pipelines, and distributed IoT sensor arrays that continuously monitor and optimize production environments.

AI systems function as essential infrastructure in F&B, connecting physical operations with analytics and automated decision-making. Engineering priorities include data consistency, low-latency inference, and model interpretability, all of which are managed alongside established requirements for food safety and process validation.

Aligning F&B with the Demands of a Digital Era

Food and beverage producers contend with demand variability, supply chain disruptions, labor shortages, and heightened sustainability requirements. Addressing these challenges requires deploying smarter, more efficient systems.

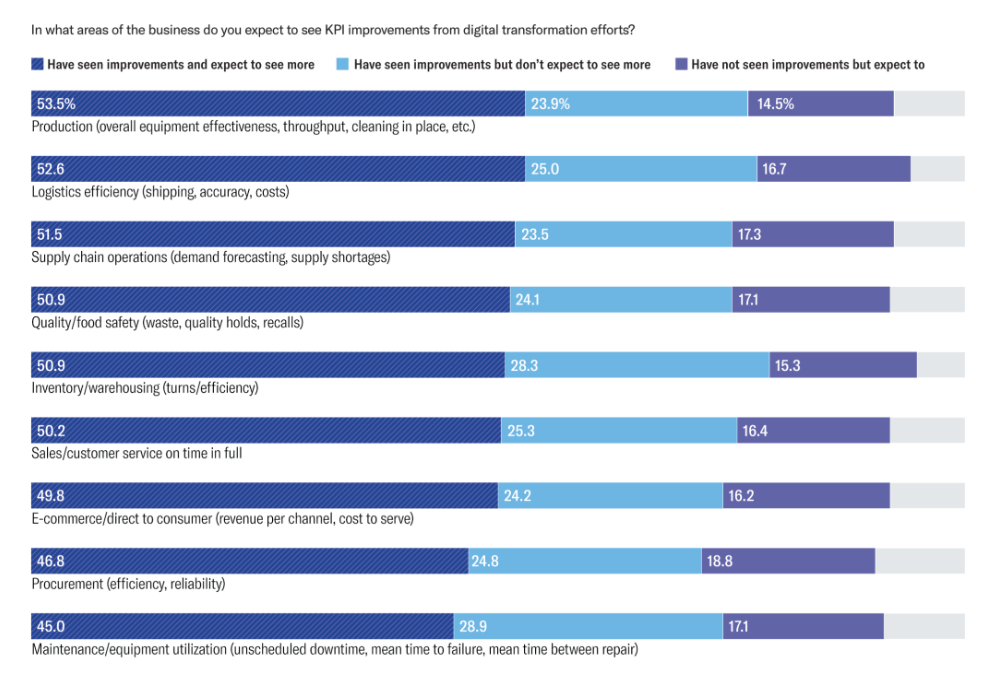

Many are turning to digital transformation to address changing operational constraints. According to IDC’s June 2022 survey, 75% of F&B executives reported measurable performance improvements post-digital adoption. About half expect further improvements as these efforts mature.

Food and beverage makers are improving business outcomes through digital transformation.

Generative AI is creating substantial economic value across consumer industries. Natural-language interfaces help consumers refine choices by interpreting constraints such as dietary rules, flavor preferences, or ingredient availability. Retailers use the same underlying models to map consumer signals to recommendations and promotional strategies with greater precision.

What is notable today is not only how AI interacts with customers but how it models operational complexity. Modern systems can ingest structured data (e.g., recipe specifications, labor availability, equipment telemetry) alongside unstructured inputs (e.g., text queries, images). This enables workflows in which AI serves as a reasoning layer, evaluating production feasibility, ranking alternatives, and estimating preparation times.

AI is becoming both a decision-maker and a creative system. It refines operations while producing new concepts through generative models. This dual role is changing how the industry approaches product innovation.

How AI is Rethinking Culinary Creativity

Recipe learning systems operate using structures similar to advanced language models. They process ingredient combinations, preparation techniques, and context-specific cues to develop a statistical understanding of cooking methods.

Retrieval engines link available ingredients, dietary requirements, and flavor preferences to viable recipes. Computer vision and natural language processing modules enable users to submit a photo or scan of pantry items, and receive tailored recipes in seconds.

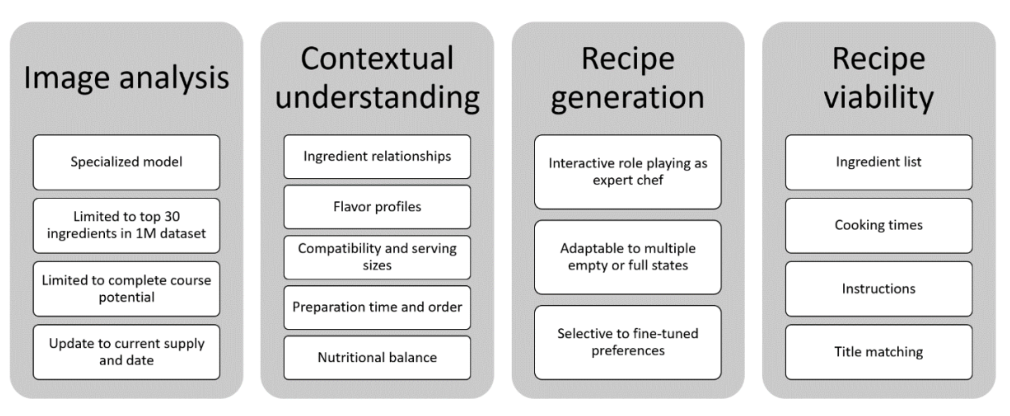

A modular AI cook application typically follows this pipeline:

- Ingredient detection: Identifies and labels available ingredients using specialized models and dataset references.

- Context evaluation: Assesses ingredient relationships, flavor profiles, serving sizes, preparation order, and nutrition.

- Recipe creation: Simulates expert chef reasoning to create recipes adapted to preferences and constraints.

- Validation: Checks ingredient lists, cooking times, instructions, and the relevance of the title.

Steps of a modular AI cook application based on the API pipeline approach

Source: The Multimodal And Modular AI Chef: Complex Recipe Generation From Imagery | arXiv

Multimodal AI platforms can now reverse-engineer recipes from photos. For instance, the “inverse cooking” system built by Facebook AI researchers combines neural networks that identify ingredients in a dish and then generate a plausible recipe. It’s an efficient model for both professional chefs and home cooks seeking inspiration from social feeds or fridge contents.

Research on prompt optimization for recipe generation found that phrasing affects recipe coherence, ingredient pairing, and clarity. Well-structured prompts produce complete, realistic instructions. With stronger data models and prompt control, AI-generated recipes are now practical and inventive.

These technologies move beyond convenience. They enable recipe design that reduces waste, dynamically adapts menus, and supports nutritional customization. AI in cooking has become a productivity layer that expands creative choice rather than limiting it.

The Rise of AI-Powered Systems for Order Management

Image: Baristas using smart assistance by PeopleImages | Shutterstock

AI is making an impact behind the counter, where speed, quality, and consistency matter with every cup. Food and beverage preparation now relies on a mix of connected hardware, sensors, and predictive algorithms to support staff and improve service.

Victoria Arduino’s Eagle One VIS, for example, includes a Virtual Intelligent Scale that calculates correct coffee doses and tracks extraction consistency. The barista enters a target weight, and the system adjusts automatically. This limits error, reduces waste, and ensures steady quality.

In Starbucks stores, real-time assistance is provided through Green Dot Assist. This conversational AI tool provides real-time support for baristas using in-store tablets. Workers can ask for recipe details or preparation steps and receive answers instantly without leaving the workstation.

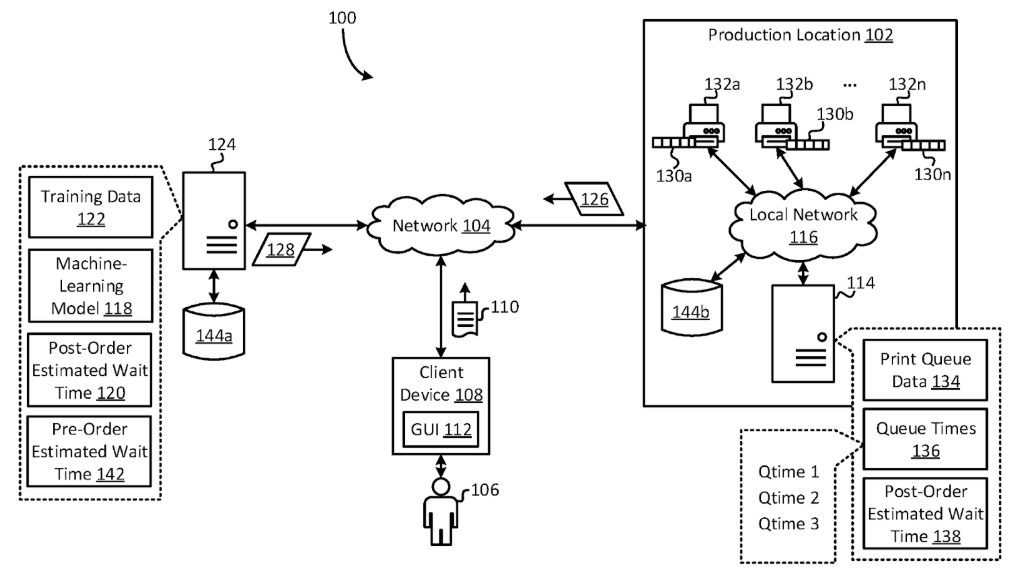

A more technical challenge is estimating wait times for complex beverage and food orders. At Starbucks, we developed and patented a machine-learning and print-queue-based system for this purpose. As depicted in FIG. 1 of our patent, the setup operates in several coordinated steps:

- Aggregate data from multiple “production stations” (e.g., cold beverage, hot beverage, food prep) by analyzing “print queues” from on-site printers (labeling systems linked to each station).

- Calculate queue times for each station by parsing queued items and summing their estimated preparation times, which may be dynamically adjusted based on item complexity or modifiers (e.g., added syrup, alternative milk).

- Determine the overall order wait time by selecting the maximum estimated wait time across all production lines, ensuring customers receive an accurate estimate based on actual kitchen workloads.

FIG. 1 shows a block diagram of an example of a system according to some aspects of the present disclosure.

If a cloud-based machine learning model is unavailable, the system falls back to a local estimation process. This fallback method relies on live queue data and applies adaptive multiplier and buffer factors that account for parallel processing or typical delays. The goal is to keep the estimate timely and accurate, even during network outages.

AI does more than assist with drink preparation or queue management. These systems can also track roasting data, monitor inventory, and analyze supply chains. Every datapoint, from bean sourcing to cup delivery, feeds into a larger feedback loop that links production insights directly to what the customer experiences.

Behavioral and Operational Data: Driving Efficiency and Insight

The most valuable resource in the modern food industry is data. Every purchase, review, and preference informs recipe development and marketing strategies, while real-time production metrics and order fulfillment histories optimize daily operations.

Diageo’s FlavorPrint technology is an example. Acquired through Vivanda, FlavorPrint creates a digital profile of taste by analyzing answers to a short questionnaire and comparing them to a database of flavor patterns. It predicts which beverage types each person is likely to enjoy. The tool adds value across both marketing and product development by tying sensory data to consumer choice.

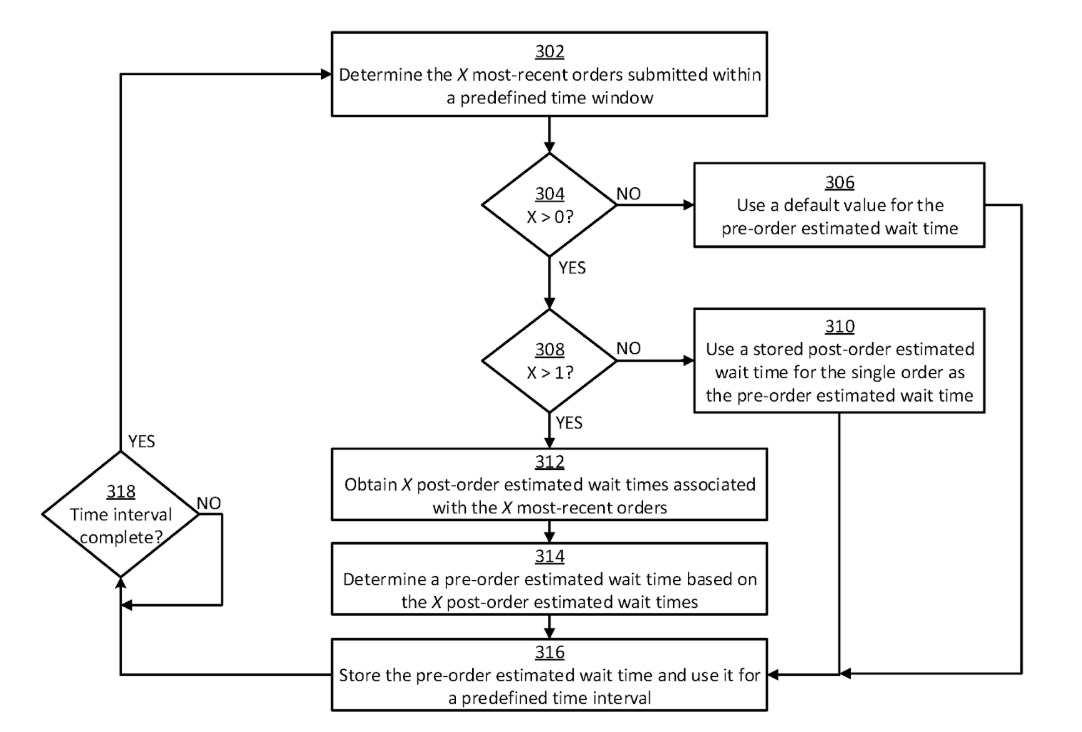

When it comes to operational efficiency, advanced AI platforms synthesize point-of-sale data, live production metrics, and fulfillment history. Our patented system, for instance, streamlines order management and resource allocation by continuously aggregating and analyzing recent order and wait-time data.

FIG. 3 shows a flowchart of an example of a process for determining a pre-order estimated wait time using an averaging technique according to some aspects of the present disclosure.

As shown in FIG. 3, the system continuously gathers fulfillment times and relevant metadata from recent orders, processes this data using averaging or weighting techniques, and generates updated wait-time estimates. These predictions inform real-time workflow scheduling and resource deployment.

Across the industry, AI-powered platforms help businesses interpret operational signals, monitor shifting demand, and respond swiftly based on live analytics. This integrated approach moves decision-making from assumptions to actionable, data-informed strategies.

Future Horizons: Connected Systems and Sustainable Growth

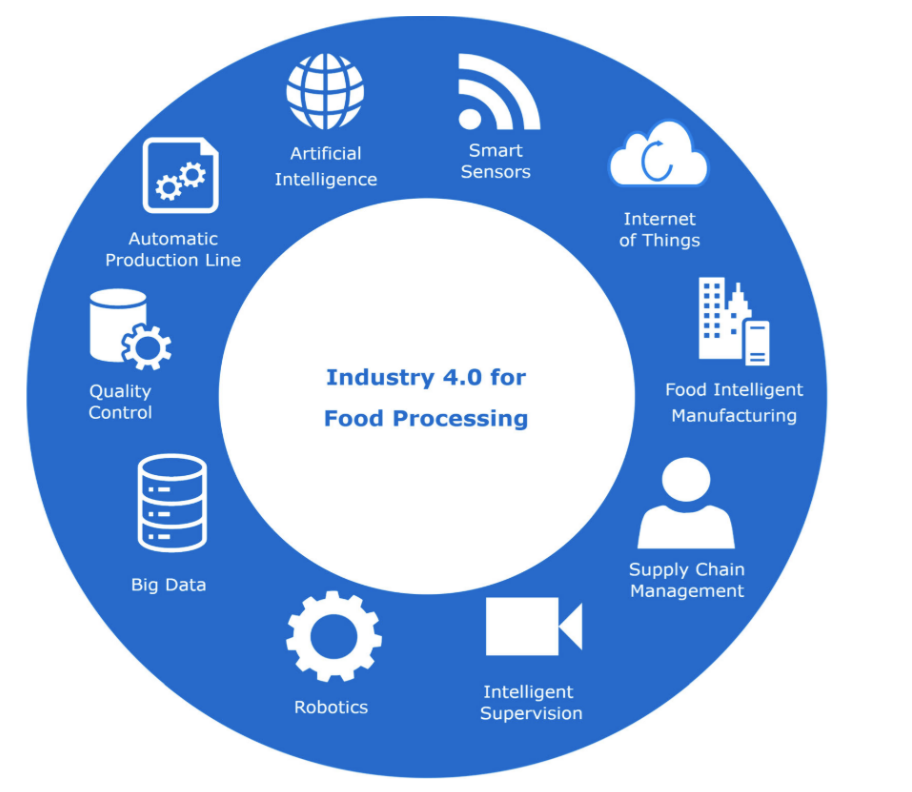

AI in food production is shifting from isolated tools to full ecosystem integration. Industry 4.0 technologies such as AI, robotics, IoT, and big data are being combined to improve precision, traceability, and sustainability.

Research on key AI applications related to food production identifies several trajectories, including:

- Robotic food assembly lines: Automated systems prepare dishes with greater precision and lower waste.

- 3D-printed ingredients: Machine-learning designs plant-based, functional foods optimized for nutrition and flavor.

- Digital twins: Virtual replicas of production sites test variables safely and strengthen quality control.

Key technology elements related to Industry 4.0 for food processing

Source: The Application of Artificial Intelligence and Big Data in the Food Industry | MDPI

Generative AI is also influencing sustainability strategies. Algorithms can evaluate ingredient substitutions that minimize environmental impact or predict spoilage to improve inventory accuracy. When connected to IoT sensors, these systems create a transparent view of the whole food lifecycle.

As these capabilities expand, new expertise will be required. The next generation of professionals must understand both data science and food technology. Policy frameworks must also adapt to ensure that innovation aligns with safety, transparency, and responsible data practices.

Final Thoughts: The Co-Creative Future of Taste

Culinary expertise has traditionally relied on experience and sensory judgment. With the integration of AI-driven systems, operational decisions can now be informed by continuous data streams, quantitative modeling, and feedback-driven optimization. Recipe retrieval and intelligent beverage systems demonstrate how digital methods can maintain consistency while enhancing creative range.

For business executives and technical leaders, the next step is to architect interoperability among AI modules, IoT devices, and production management systems. The F&B sector provides an ideal testing ground for practical AI, where measurable efficiency meets real consumer experience. The companies that lead this transformation will be those that treat data with the same care once reserved for sourcing and taste.

About the Author:

Harsh Nigam is a senior technical lead with over twenty years of experience in software development, architecture, and AI systems. He specializes in scalable, data-driven solutions that enhance efficiency and user experience. Harsh holds a Master’s degree in Computer Applications and advanced certifications in computer science.