Every manufacturing company has one main goal – to produce exactly the amount of product to meet demand. No more. No less. This requires manufacturers to maintain proper stock levels, address seasonality sales, all the while ensuring available equipment and appropriate personnel. It’s a tall order but AI-powered demand forecasting brings it down to size and delivers the results.

Yet there remains a notable gap in the adoption of AI technologies such as machine learning (ML) within the manufacturing industry. McKinsey reports that a significant 73% of enterprises continue to rely on manual or outdated forecasting methods. But when the cost is high, manufacturers can no longer hold off taking the AI plunge with demand forecasting. Chris Butcher, Data & AI Presales Solution Architect at Columbus explains how ML technology can address these issues, and importantly how manufacturers can decide where and when to use it to get most success.

Everything from optimised production and inventory levels to flexible pricing, budgeting and hiring rely on accurate decision-making. But factors such as capacity, demand and cost aren’t always known parameters, especially when influenced by natural disasters or geopolitical tensions. Variations in supplies, transportation and lead times only add to these uncertainties, which can greatly influence supply chain performance with widespread effects on production scheduling and inventory planning.

What can technology offer to address this challenge?

Here’s where real-time data integration can enable manufacturers to gather and analyse data for more precise forecasting that can better handle the “unknowns”. ML plays a crucial role in this by improving the accuracy of demand forecasting, especially when it comes to avoiding the traditional challenges associated with planning such as long delivery times, high transport costs, and high inventory and waste levels. With assistance from ML technologies, manufacturers can increase their value generation, heighten customer satisfaction and sustain a competitive edge.

The common pitfalls of traditional demand forecasting

- Time-consuming forecasts that limit quick adjustments

- Inaccurate forecasts that cause costly overstocking or understocking

- Failure to factor in external events and market changes, which reduces the ability to adapt to unforeseen circumstances

- High costs of maintaining a demand planning team and expensive forecasting tools

To live the impossible dream!

ML, when integrated into supply chain management systems, addresses all of these issues by leveraging advanced algorithms, data analytics and pattern recognition to provide more precise and actionable insights for manufacturers to navigate uncertainties.

ML-based forecasting can substantially reduce errors by up to 50%, allowing manufacturers to do the impossible – anticipate demand with enough time to manufacture the right stock and get as close as possible to producing the exact amount needed to meet future demand.

So how can manufacturers get started on their AI journey?

1. Build resiliency into supply chains with strategic partnerships

Effective demand forecasting is vital for procurement and supplier management. For instance, manufacturers can use ML-generated insights on future demand patterns to collaborate closely with suppliers and ensure the timely availability of raw materials and components.

This minimises lead times, reduces the risk of production delays due to shortages and allows for negotiation of favourable terms with suppliers. This can help manufacturers, especially those looking to regionalise their operations, create more resilient supply chains. Accurate forecasts also enable organisations to order materials in appropriate quantities, which can prevent overstocking and reduce carrying costs.

2. Trim waste to boost savings

Yet it’s not just carrying costs where ML-based forecasting can bring financial reductions. Accurate forecasts enable efficient resource allocation, meaning raw materials, labour and equipment are used effectively, which can minimise waste and allow manufacturers to maintain efficient production processes.

The numbers don’t lie! According to McKinsey, applying intelligent forecasting to supply chain management can reduce errors by between 20% and 50% – and translate into a reduction in lost sales and product unavailability of up to 65%. But that’s not all. Continuing the virtuous circle, warehousing costs can fall by 5 to 10%, and administration costs by 25% to 40%.

3. Don’t forget the untapped revenue opportunities

ML-based demand forecasting can be a vital way for manufacturers to grow revenue. By aligning production with anticipated demand, manufacturers can strike a balance between holding enough stock and meeting customer requirements. This can significantly help improve cash flow and operational efficiency. But that’s not all.

ML-based demand forecasting ensures products are available when customers are ready to purchase. This optimised product availability can capture more sales opportunities and maintain high customer satisfaction levels. Additionally, accurate demand forecasting allows manufacturers to plan for peak demand periods, optimising sales even during seasonal trends and holidays.

Are you data ready? Laying the data groundwork matters

Before AI can delivery results, manufacturers need to get themselves data-ready. Many organisations believe their processes are in order. In reality, shortcuts and workarounds exist. Unless these are identified and fixed, technology may end up reinforcing inefficiency rather than solving it.

It can be tricky to collect sufficient historical data and ensure its quality, particularly for new products or emerging markets. But even well-established companies and products often do not have historical data, or this data is not reliable and accessible. The same applies to KPIs, as activity isn’t the same as purpose. Organisations need the right KPIs to track meaningful outcomes. But that’s not the only hurdle. Choosing the right ML algorithm and optimising its parameters can be complex, while the interpretability of these models may be limited.

Before you start, dig deep for quick AI wins on the factory floor

Production lines aren’t playgrounds, they’re where the work is done. So the key is to start small and focus on use cases that may not directly affect production itself but still impacts workers.

Manufacturers can take the time to ask the right questions upfront to understand where the business value is. Organisations can look at where they can take cost out of the business or tackle issues that cause downtime, delays or wasted effort. It might be something as simple as making time recording more efficient.

Manufacturers that start with relatively low-cost, quick wins, can show that AI works in practice. It might be a slow approach at the beginning, but it ensures organisations are able to speed up later. A small proof of concept not only tests readiness for AI but also builds trust amongst the workforce which is key to securing buy-in.

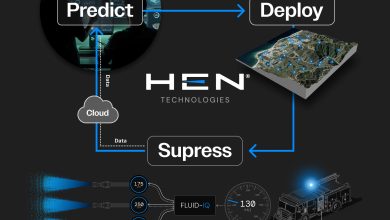

Turn predictive insight into manufacturing advantage

It might not be a crystal ball but demand forecasting with the support of machine learning gives global supply chain leaders the accuracy and flexibility they need to stay one step ahead of customer demand. Amid demand uncertainties, using a machine learning model has the greatest influence on supply chain performance and can make the difference in today’s competitive manufacturing landscape.