Warehouses are busy places. But most slowdowns start at one spot: “the dock”. Trucks arrive in a problematic manner, drivers wait, crews sit idle or scramble to manage, and the whole day slips off plan. If you fix the dock, you fix a lot of problems downstream. This post explains why dock scheduling matters and how practical tools like Arrivy’s dock scheduling, live tracking, and digital paperwork turn a problematic dock gate into predictable throughput.

The Root Cause of Warehouse Bottlenecks

Think about your last bad day at the warehouse. A trailer shows up early. Your dock is full. Forklifts pile up. People start doing work that shouldn’t be done yet. That scene repeats in different forms, but the causes are often the same.

-

Delays at docks and loading bays

Ideally, drivers should arrive, dock, unload, and leave. Instead, trucks wait unnecessarily in a typical scenario. A single 30-minute wait can cost hours when it disrupts sequencing, pushes back the next load, and leaves crews without clear tasks. Waiting trucks also eat yard space and create safety hazards. The simplest truth is that idle trucks mean idle people and wasted capacity.

-

Poor scheduling of carriers and trucks

Most scheduling still relies on phone calls and spreadsheets. Someone books a slot, someone else changes it, and the updated info never reaches the team on the floor. That creates double bookings, unexpected arrivals, and empty windows that could’ve been used. When you manage truck arrivals by habit instead of rules, you leave capacity on the table.

-

Lack of real-time visibility into shipments

If you don’t know whether a truck is five minutes or two hours away, you can’t stage staff properly. Managers end up moving people, calling drivers, and running back to the gate. That reactive activity is expensive and exhausting. Live visibility gives you time to prepare for such scenarios.

-

Ripple effects on supply chain fulfillment

A late inbound load inconveniences dock workers, delays picking, affects outbound schedules, and can miss retailer cutoffs. That missed window then forces rush shipments, overtime, and angry calls from customers. Fix the dock and you remove a major source of those ripple effects.

Why Dock Scheduling Is the Hidden Key to Warehouse Efficiency

You can call it dock scheduling, appointment management, or truck appointment systems. The idea is simple: treat dock time like any other scarce resource and manage it. When you do that, you improve costs, labor use, and customer reliability.

Coordinating carriers, shippers, and warehouse teams

A shared schedule means everyone knows what to expect. Carriers see available times and pick a slot that fits their route. Shippers can plan pickups that match outgoing loads. Warehouse teams can schedule staff to match arrivals. That single shared plan stops dozens of small interruptions before they start.

For example, instead of five trucks showing at once at 9 a.m., carriers book 30-minute slots spread out through the morning. Your crew has time to unload and clear the bay before the next truck arrives.

Reducing detention fees and dwell times

Detention fees are a real cost, and they rise quickly. When trucks wait less, detention fees fall, and drivers are happier. Shorter dwell times also mean trucks can return to the road sooner, which improves your carrier relationships and reduces transport costs.

Smoother inbound and outbound logistics

When dock times are predictable, incoming trucks get unloaded into the right lanes and outbound trucks leave on schedule. That steadiness reduces rush jobs and helps you meet promised delivery windows.

How Supply Chain Warehouse Management Software Solves Bottlenecks

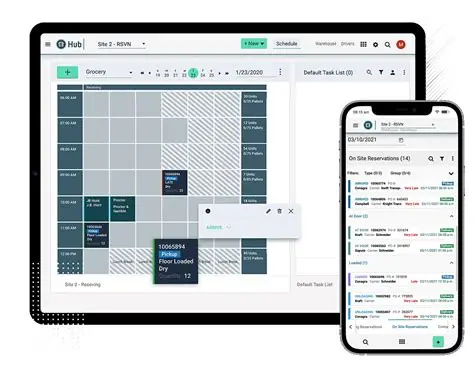

A supply chain warehouse management software makes booking, tracking, paperwork, and analytics work together. Here’s how that plays out in practice.

Integrated dock scheduling & truck appointment systems

A proper dock scheduling system publishes available slots and enforces rules: which bay, truck size, equipment needed, and buffer times. Carriers can book from a link on a phone. Your team sees the confirmed calendar. And delays and cancellations are handled automatically, removing manual steps that cause mistakes.

Real-time Shipment Check-in and Communication

As trucks arrive, drivers can check in digitally at the warehouse entrance, and the system updates dock staff in real time. This cuts down on phone calls, speeds up dock preparation, and keeps everyone aware of who’s on-site and ready to load or unload.

Delay alerts, quick rescheduling, and slot reopening

Arrivy sends immediate delay alerts so dock staff and carriers stay updated. Planners can drag-and-drop bookings on the calendar, and the system enforces buffers, team availability, and bay rules during rescheduling. When a booking is canceled, the slot reopens instantly for others to book and follows the calendar’s rules.

Digital documentation & compliance tracking

Paper forms slow down the dock and usually get lost. Contrarily, digital forms capture bills of lading, damage photos, signatures, and compliance checks, all attached to the appointment. Digital records speed audits and quicken billing. They also reduce disputes with carriers and customers.

Analytics and performance dashboards

“If you track it, you can improve it.”

Dashboards that show on-time arrival rates, average dwell time, and dock utilization highlight recurring problems. Those metrics tell you where to add staff, shift schedules, or change yard flow.

For example, a report shows Dock 3 is 30% busier on Mondays. You shift staff or reassign loads and see the average dwell time drop the next week.

Key Features to Look For in Dock Scheduling & Supply Chain Software

Key Features to Look For in Dock Scheduling & Supply Chain Software

Don’t buy features you won’t use. Focus on tools that solve your pain points.

Appointment booking portals for carriers

Drivers need a fast, mobile booking link without any login hoops. Look for software that offers clear times and instant confirmation. That stops the phone calls that distract your ops team.

Live tracking dashboards for warehouses

Your ops team needs a single screen that shows each dock, who’s arriving, and what’s in progress. Drag-and-drop adjustments and simple filters let you fix small conflicts quickly.

Analytics for capacity planning

You should be able to run a report that shows peak hours, dock utilization, and carrier performance. Those numbers help you plan labor and decide when to add capacity.

Benefits for Supply Chain Fulfillment

When the dock works properly, the whole chain benefits. You see faster truck turns, higher throughput, lower costs, and better relationships.

Shorter truck turnaround times

Faster turns mean trucks do more trips a day. That makes carriers happier and can lower your freight charges.

Increased dock throughput

Staggered, enforced slots let you move more loads without adding bays. That’s expansion without construction.

Lower logistics costs

Fewer detention fees, fewer rush shipments, and less overtime reduce costs quickly.

Happier carriers and customers

Predictable gates make drivers and customers happier. That means less stress, fewer complaints, and more repeat business.

Choosing the Right Supply Chain Management Provider

A good provider does three things well:

- Core dock scheduling

- Tight integrations

- Flexible multi-site control

Ensure that your pick offers all the following:

Dock scheduling capability is a must-have

Dock scheduling should be central. The software needs to understand bays, gates, and real-world constraints.

Integration with WMS/TMS systems

Appointments must sync with orders and route plans. Open APIs or native connectors prevent duplicate data and manual errors.

Flexibility for multi-warehouse operations

If you run more than one site, manage them from one dashboard while complying with each site’s rules. That gives you visibility and the ability to shift capacity where it’s needed.

Industry Use Cases

3PLs managing multiple customers at the same warehouse

3PLs can let clients book within preset rules while keeping a master schedule. That prevents conflicts and preserves service levels across customers.

Manufacturing, transport, and logistics operations

Tie appointments to production schedules so inbound materials arrive when needed and finished goods leave on time.

Retail and e-commerce warehouses

Publish limited slots during peak seasons. Avoid the “too many trucks at once” problem during promotions and sales.

Quick Wins You Can Start This Week

- Share a carrier booking link with your top five carriers. Track calls and cancellations for two weeks.

- Put one dock on a live calendar and measure average dwell time. Run the same measure after two weeks and compare.

- Require a photo and signature for every appointment to speed claims and billing.

- Pull a weekly report on average dwell time by dock and change staffing where needed.

These small actions give measurable wins fast.

Conclusion

Dock scheduling is the hidden lever that fixes a lot of warehouse problems. Treat dock time like a resource, use live tracking, capture digital records, and measure results. Those steps reduce wait times, raise throughput, and cut costs.

If your dock slows you down, start small with one booking link, one dock, and two weeks of data. Tools like Arrivy make it easy to run that test and scale what works. When your gate stops being a headache, the whole supply chain runs better.

FAQS

How does dock scheduling reduce warehouse bottlenecks?

By giving trucks set appointment times, dock scheduling spreads out arrivals, cuts down long wait lines, and keeps loading bays moving at a steady pace.

What is a dock scheduling system in supply chain management?

It’s a digital tool that lets carriers book time slots at a warehouse dock, helping shippers, carriers, and warehouse staff coordinate truck arrivals and departures.

What are the benefits of using supply chain warehouse management software for truck scheduling?

It shortens truck turnaround times, reduces detention costs, and makes warehouse operations more predictable.

How does a carrier appointment system work?

Carriers log into a portal or scheduling system like Arrivy to reserve dock slots. Once confirmed, warehouse teams can plan labor and equipment around those appointments.

Can dock scheduling reduce detention fees and dwell time?

Yes. When trucks get a set time to load or unload, they spend less time idling on site, which directly lowers detention charges and wasted driver hours.

How does dock scheduling integrate with warehouse and supply chain management software?

Arrivy connects with inventory, order, and transport systems (e.g., MoversSuite) so shipments are tied to specific dock appointments. This keeps inbound and outbound flows aligned with the bigger supply chain.

How does supply chain software reduce warehouse bottlenecks?

Supply chain software like Arrivy creates visibility across trucks, docks, and orders, helping teams adjust schedules, allocate labor, and avoid overloads at busy times.

What should I look for in supply chain management providers?

Look for strong dock scheduling tools, real-time tracking, and integrations with WMS/TMS systems. Flexibility for multiple warehouses is also key.

How is supply chain software different from warehouse management systems (WMS)?

WMS focuses on what happens inside the warehouse (inventory, picking, packing). Supply chain software extends beyond that to coordinate transportation, carriers, and dock scheduling.

Can small warehouses benefit from supply chain software management?

Yes. Even smaller sites struggle with truck wait times and scheduling conflicts. A simple dock scheduling tool can free up labor hours and improve carrier relationships without needing major investment.

Key Features to Look For in Dock Scheduling & Supply Chain Software

Key Features to Look For in Dock Scheduling & Supply Chain Software