Robot employment agency MusashiAI today announced the commercial availability of two new robot workforce products to their product suite that include the autonomous visual quality control inspector and an autonomous forklift driver that is powered by a disruptive mobile robot fleet management system.

Live trials of the technology were announced and conducted in December 2019 in Musashi Seimitsu’s factory with the robot employment agency claiming that in less than 6 months of testing, the results had exceeded expectations and overcome technological barriers known so far in the autonomous industrial robotic market.

Ran Poliakine, co-founder of MusashiAI said: “The goal of the joint venture with Musashi Seimitsu has always been to work towards our vision of Industry 4.0, where human workers do human jobs and are not trapped in manual industrial jobs. The interest from Musashi Seimitsu coupled with our latest finalised proof of concept trials with a world-leading manufacturer and three leading Israeli logistics companies is a great sign of confidence in our technology and the gifts it brings to the future of humanity. I am excited about the company’s next steps.”

Since COVID-19, automation and robotics have become increasingly popular especially with businesses in the manufacturing and logistics department looking for solutions to keep up with their workloads despite having a reduced workforce and having to adhere to social distancing measures.

MusashiAI is joined by other companies who are looking to innovate in this area while investors are quickly realising the potential of automation and robotics across a variety of sectors with recent examples being Pudu Robotics raising more than $15m and autonomous mobile robot provider OTTO Motors raising $29m.

MusashiAI is a joint venture between Japanese based Musashi Seimitsu, which is a Honda Motor Corporation affiliate company, and Israeli based SixAI who claims to be the world’s first robot employment agency.

The companies each bring their own unique expertise to the joint venture with Musashi Seimitsu having 33 manufacturing plants across four separate continents under its name and SixAI having a track record of creating significant value in AI-Robotics companies and its intellectual property.

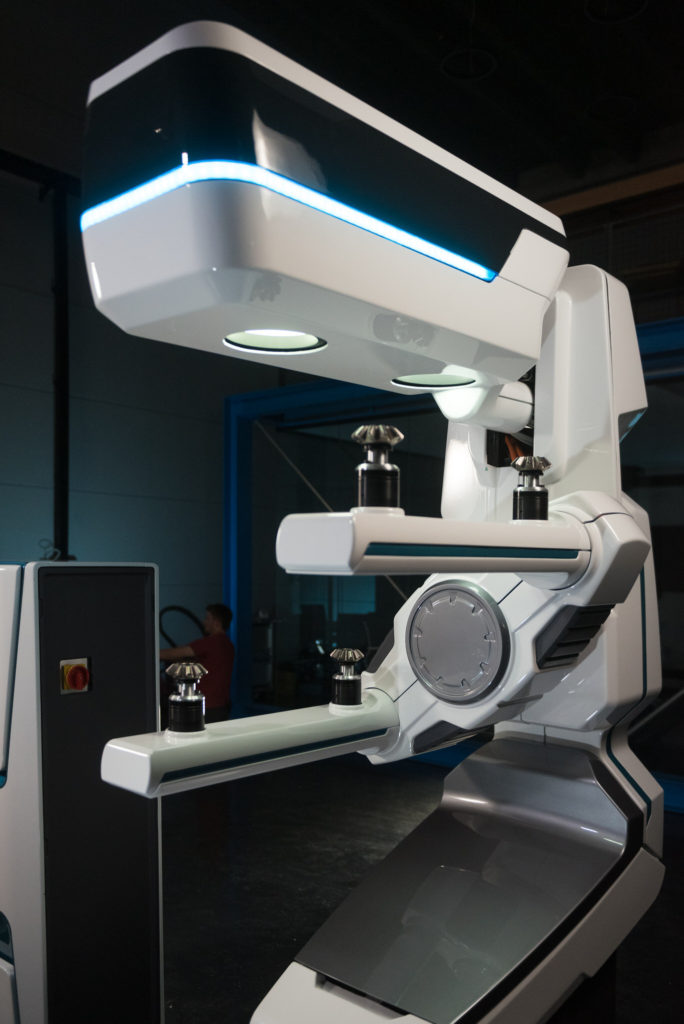

The robot employment agency explained that human workers have been employers’ pick for the visual quality control inspection of final industrial products because robots have not been able to surpass or even match the human ability to detect and identify surface defects quickly and accurately.

Poliakine added: “Globally, nearly 30 million people work in gruelling visual inspection jobs. Many of these people suffer chronic health conditions from this work, such as carpal tunnel syndrome. No doubt a large number of them have been furloughed because many industrial settings are unsafe now due to the coronavirus. These people are not key workers, but what they do is essential. Businesses will need their final products inspected, and we are offering the world a solution which can shield employees from this deadly virus and the chronic health problems associated with their work, and the major economic danger of stalling business for much longer.”

The new product launches from robot employment agency come after the recent reveal of them securing a POC for their autonomous Quality Control Inspector with one of the world’s largest bearing manufacturers.

The company claims that they will be conducting three POCs for the autonomous forklift drivers and central management system with leading Israeli retail and FMCG groups starting Q4 of 2020 and will be the first agreements where the robots are going to be tested outside of Musashi Seimitsu’s facilities.

The robot employment agency explained that existing robotic solutions for visual quality inspection of surface defects in manufacturing lines typically have low accuracy rates and detection speeds.

However, with the completion of their live trials, MusashiAI has said they have confirmed that their autonomous robotic visual inspector exceeds the speed, accuracy, and stamina of humans in a ‘world-first’ robotic capability advance.

“To our knowledge, current market incumbents do not offer visual quality control inspection robots which surpass the skills of human workers. Moreover, the majority of the visual inspectors available on the market inspect full assembly parts or geometric defects. Our visual inspector detects tiny surface defects, which is a far more complicated and labour-intensive task,” added Poliakine.

The robot employment agency noted that their freshly introduced autonomous forklift driver is navigating and directing itself using the companies proprietary fleet management system.

The proprietary fleet management system employs sophisticated perception and decision-making software which in combination with inexpensive industry-standard HD cameras can predict incidents and as a result can lower the risk and probability of accidents happening.

The company explained that the autonomous forklift navigates routes amongst humans through a technology that combines cameras with a birds-eye view and a central processing unit.

The trials confirmed that logistics tasks previously limited to human forklift drivers can now be autonomously performed by the newly introduced autonomous forklift robots while potentially increasing efficiency, being cost-effective, and meeting safety standards.

Poliakine explained what the vision behind the new robot products added to their suite was by saying: “These robots are designed with people in mind – the vision is that they integrate easily onto the production floor where there will still be some human workers, but release other works from this particular drudgery. They are friendly looking and easy to deploy wherever they are needed. Our OPEX model means clients can deploy robots when and where they need them, without extensive CAPEX.”

The robot employment agency explained that an advanced form of deep learning which parallels the way the human brain absorbs and assimilates information was developed, making redeploying and switching their robots between tasks easier and will make them better prepared for the various socially-distanced industrial settings to come.

MusashiAI wrote that they have the ability to customise their robots to suit the needs of individual customers which can make the companies product suite of robotics more appealing to potential customers due to increasingly complex situations and work processes due to COVID-19.