In highway construction, most stories begin with concrete, steel, and earthmovers. At a Georgia-based heavy civil and transportation contractor firm, known for its work on GDOT and federally funded projects, one story begins somewhere less visible. Inside models, dashboards, and logic trees that quietly decide how every dollar and design decision behaves over the life of a roadway.

That quiet work belongs, in large part, to engineer Harshit Sheladiya, who serves as an Assistant Project Manager / Consultant within the company’s Transportation Division. On paper, his role blends project planning, estimation, and field coordination. In practice, it has become a fulcrum for how the firm thinks about value, risk, and long-term performance on some of Georgia’s most scrutinized corridors.

From Cost Analyst to Technical Nerve Center

When Harshit joined the organization, his responsibilities looked familiar. He would build estimates for urban roadway, bridge, and drainage projects; coordinate between design consultants, GDOT officials, and environmental agencies; and support field teams with constructible plans and sequences.

Instead of treating cost estimates as static documents, he began building predictive models that linked design choices, production rates, and risk factors to long-term outcomes. Over time, his position evolved from a conventional cost analyst to a lead technical advisor on GDOT value-engineering initiatives. His remit expanded to include lifecycle performance assessments and design–build viability.

In effect, he became a bridge between the spreadsheets and the jobsite, translating data into design changes that mattered on the ground.

Reimagining Drainage and Earthwork, One Corridor at a Time

Two programs highlight how this shift played out. On the City of Johns Creek’s Jones Bridge Road Widening initiative, a major TSPLOST-funded corridor, Harshit led the design review and value‑engineering process with a focus on drainage modernization. By integrating advanced ADS technology and reworking sub‑surface layouts to better match real ground conditions, he helped optimize the system in a way that not only enhanced water quality and public safety for more than a million residents. The optimization also enabled approximately $2.2 million in documented cost savings.

A parallel responsibility came through the Fulton County Waterline Relocation Project, where he directed complex cross‑utility coordination and ensured CEI compliance under engineering oversight. His approach reduced conflicts, minimized rework, and kept the project aligned with federal and municipal expectations.

Across these and related assignments, his combined contributions yielded more than $25 million in validated savings. This strengthened the contractor’s reputation with GDOT and multiple municipal agencies, while also reinforcing a shift toward performance‑driven delivery.

In a separate City Infrastructure Enhancement Program, he worked on hybrid drainage and earthwork sequencing that re-ordered how crews approached the site. Instead of treating earthwork, utilities, and drainage as strictly linear steps, he helped design an interlocking sequence that allowed parallel work fronts while maintaining safety and quality controls. This accelerated delivery while keeping inspection standards intact.

A New Kind of Value Engineering: Digital, Iterative, and Live

Harshit’s most distinctive contribution at the organization sits at the intersection of engineering judgment and digital intelligence.

On the Georgia Department of Transportation’s SR‑9 Widening and Reconstruction Project ( a $35 million federal‑aid program), Harshit helped pioneer Georgia’s first integrated framework that merged Value Engineering (VE) with Advanced Data‑Process (ADP) analytics. Prior to this shift, GDOT contractors relied on traditional manual spreadsheets and isolated QC logs. These systems offered no unified data visibility or real‑time feedback loops between design, field execution, and compliance.

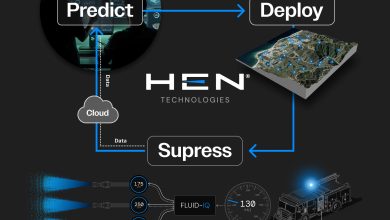

The new cloud‑based decision‑intelligence platform unified engineering optimization, cost‑function modeling, predictive analytics, and live data capture into a single operational environment. The system did several things at once:

- Used predictive analytics to understand production rates, equipment idle time, and likely bottlenecks.

- Embedded value-engineering logic trees to test alternative details and staging options against cost, schedule, and performance criteria.

- Fed data into live dashboards tracking compliance with federal requirements, including disadvantaged business enterprise (DBE) participation and reporting standards.

Instead of limiting VE to design‑stage reviews, Harshit enabled continuous optimization throughout construction using machine‑generated data and digital field sensors. This approach supported FHWA’s broader “Digital as‑Built” and “e‑Construction” modernization initiatives.

The outcomes were measurable and unprecedented for a GDOT contract of comparable scope: approximately 3% cost avoidance (around $1.05 million), a 12% reduction in equipment idle time, a 5‑percentage‑point gain in DBE compliance, and notable reductions in carbon emissions through recycled asphalt use. These results established a new performance benchmark for state–federal transportation projects.

Beyond One Company: Templates Others Can Use

Crucially, Harshit’s work did not remain locked inside a single contract file.As results accumulated, elements of the VE + analytics framework were adopted as reference models for other GDOT and federal-aid roadway programs. Templates originally designed for one corridor evolved into repeatable digital-construction analytics modules integrated into agency dashboards. Training protocols shifted to emphasize real-time data, lifecycle thinking, and sustainability.

He also documented his methods internally and shared insights externally through technical papers and presentations. His expertise led to invitations from the Georgia Highway Contractors Association (GHCA) to discuss ADS integration and lifecycle cost modeling. His insights began surfacing in GDOT’s internal VE reports and were cited by transportation professionals exploring digital workflow improvements.

Leadership in a Role That Was Never Meant to Lead

Officially, Harshit’s title at the organization remains Assistant Project Manager / Consultant. Unofficially, his remit stretches far beyond what that designation usually implies.

He coordinates directly with GDOT officials to document project-specific efficiency metrics. He supports environmental approval documentation and CEI audits, ensuring that innovations in design and sequencing are matched by regulatory compliance. He mentors DBE contractors and graduate interns, passing on both technical methods and the habit of questioning default assumptions.

Projects under his guidance consistently exhibited tighter cost variance and better schedule adherence than departmental norms. More importantly, they became examples of how a mid-sized contractor could meet, and in some cases anticipate, the federal push toward “Digital as-Built” and e-construction practices.

In a field often defined by machinery and materials, Harshit Sheladiya’s work shows how much of modern infrastructure actually depends on something less visible: the ability to see patterns in data, to question inherited workflows, and to design systems where value is measured not only in what gets built today. His approach focuses on how infrastructure performs, and what it costs, over decades.

Georgia’s roads will keep expanding. Thanks to engineers like him, they may do so with a little more intelligence, a little less waste, and a much clearer picture of what “value” really means.