Air knife systems are one of these technologies that are perfect for businesses that need to be both efficient and environmentally friendly. They enable businesses to take significant steps toward accomplishing their sustainability goals by substituting energy-intensive procedures. The use of air-based cleaning and drying technology is arguably the most sought-after innovation in creating this greener, cleaner production. Mechanical errors, hygiene issues, and labeling issues might result from condensation from freezers or excess water from rinsing stations. In this case, air knife systems are essential.

Overview

Air Knife systems offer a more energy-efficient alternative to compressed air or manual drying methods. This efficiency results in discernible cost savings during high-output seasons like summer. Moisture can lead to conveyor belt blockages, package sliding, and sensor problems. Product drying at key transfer locations keeps line efficiency high and minimizes downtime from cleanup or mechanical issues.

Most of these solvent-based cleaning agents simply disappeared, negating the need for blow-off or other drying methods. Although it was still in its early stages, the printed circuit board industry initiated the transition to aqueous and semi-aqueous-based parts cleaning technologies.

water-based paints, varnishes, adhesives, inks, and other solutions used in many different manufacturing industries. Due to the Montreal Protocol and worldwide industrial commitment to environmental stewardship regulations, the hitherto specialist industry of air knives became an industry.

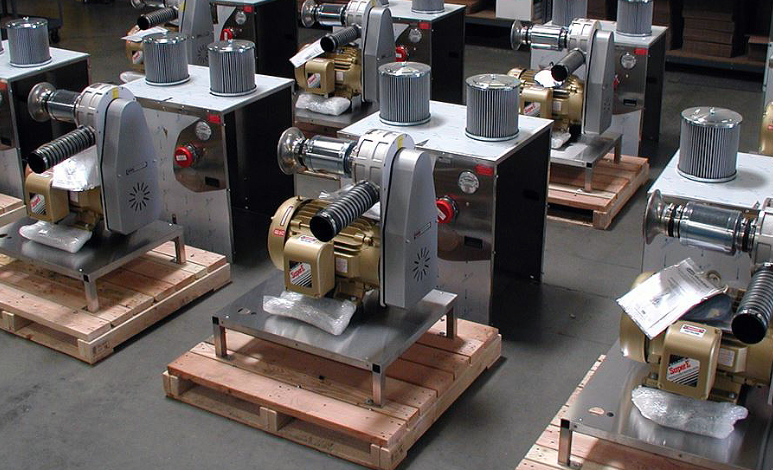

Air knives on a production line usually have discharge air slots or holes between 0.001 and 0.25 inches (0.025 and 6.350 mm) and lengths between 0.25 and 200 inches (6.4 and 5,080.0 mm). One to twelve air knives may be required for a stationary air knife setup, depending on the needs of the application. To produce the necessary exit air volume and velocity, air is blasted through the air knife slits by an air generator, such as an industrial blower or air compressor.

There are several application, environmental, efficiency, and duty cycle considerations to examine when choosing between compressors and blowers. Compressed air, which is the least effective when utilized for air knives that release into free air, can be combined with primary plant air. Because the piping sizes that supply the air knives can be as small as 1½4 in (6.4 mm), they are ideal for compact spaces. The cost savings on electricity significantly surpass the efficiency advantage over compressed air, even though larger supply pipes and blower-powered air knives are needed.

In conclusion

There are many different industries, situations, and uses for air knives. Air knife designs that can release invisible, high-velocity air streams come in a wide variety of shapes and sizes. These include low-precision “garage built” devices and the most exotic metals utilized in air knives for class 100 clean rooms.

When it becomes essential to minimize noise and control moisture surrounding a conveyorized air knife installation, several production facilities have installed air knives inside an enclosure. These enclosures eliminate any liquid that could be dangerous, contain water, and reduce air knife noise.

Many manufacturing plants have placed air knives inside enclosures when it becomes necessary to reduce noise and manage moisture around a conveyorized air knife installation. These enclosures reduce air knife noise, hold water, and remove any potentially hazardous liquid. The most common component of an air knife is a structure, typically composed of steel, aluminum, or plastic, that contains a plenum chamber and has a distinctive knife-edge-like design on one side consisting of two blades connected together.