Heavy and ungainly machines have ruled the factory floor for decades. These were systems that were solid and dependable. The big machines, which were very inflexible, proved to be a problem as markets changed and product requirements became more diverse. They were costly to keep up and power hungry, and they required specialist users. It is 2025, and the world of making things is now in a state of change. Now come the visionary vendors, tens of whom are laboring on smarter, smaller, and more modular tools that will serve a wide range of uses. Xlaserlab is leading this change with the second generation line of intelligent modular laser systems that takes performance and flexibility to the next level for current production.

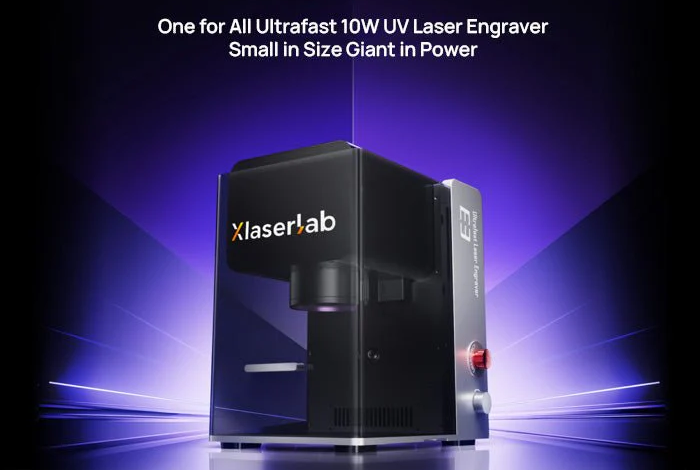

Our mission at Xlaserlab is simple, if not powerful – to make laser technology innovation more accessible for all manufacturers. Its strategy isn’t to create one huge and complicated system, but instead to make smaller modular units that can accomplish a range of tasks efficiently. Every unit is compact and lightweight will connect to other units. With such freedom at your fingertips, companies clearly have full oversight of their production setup. If a factory is scaling up or otherwise changing its workflow, it can adjust the setup rather than having to replace an entire system.

Smarter, Faster Lasers for the Modern Factory

A beautiful thing about Xlaserlab’s invention is that it scales. The company’s laser systems, on the other hand, are designed to be free-standing capsules that can mount and/or dismount as needed. For example, one module could be for laser engraving for wood, and the other for laser engraving on metal that is meant to be used in industries. Modules offer superior precision and smooth results, also on uneven materials.

It also means that these systems occupy only a fraction of the space required by legacy heavy machinery. They are small enough to plunk onto a factory floor, in a design studio, or into startup production. I think it’s a good thing for the small and mid nozzle manufacturers that need access to the same level of professional programs without dealing with all of this infrastructure.

User-friendliness was also what Xlaserlab aimed at. Both areplug-and-playy. Long installation, time-consuming setups are not on the table. Laser modules with on-the-fly synchronization. Once the laser modules have been connected, it is possible to adjust the module flash interval automatically. This reduces offline time, provides continuous production. It is easy to operate and is designed for a quick start for less experienced operators.

Another key advantage is maintenance. Should one module break or get dirty, the system keeps running. It could be advantageous in the sense that there is no downtime for the entire production line. It also spares businesses additional time and cost, as it would be lost to service disruption.

Another characteristic of these laser systems is their energy efficiency. Xlaserlab products use low electric power without loss of output. They’re made with A/C hot-and-cold cooling technology that can prevent units from getting warm and decreasing their life expectancy. For the manufacturers, the cost of operations comes down and the life-cycle of their equipment goes up.”

A modular system of the above generic type with those features is particularly useful for applications in automotive and medical engineering or consumer electronics. All of these areas need precision, but they also need flexibility. Xlaserlab’s modular units offer both. Repeatable accuracy, ease of use are giving manufacturers a competitive edge.

The company’s R&D team is still focusing on proprietary modules based on specific requirements from various fields. Some of these are more suited to super high-speed cutting, and others focus on ultra-fine engraving for the tiniest materials. The idea is to let each client build its own infrastructure, according to the resources it produces, rather than squeezing them all into a range of single size range.

As more manufacturers become digitalized and automated, the road points towards modularity. Smartmodules from Xlaserlab are suited for a digital monitoring system. Fetch Managers can remotely monitor performance, schedule maintenance and make adjustments. These small but significant improvements are the fundamentals of what the “factory of the future” will look like: efficient, compact, and smart.

Redefining Flexibility for Future Manufacturing

It’s not just the same replaced with other sameness, a resource-sucking machine industry traded for one of modules or modular systems, it’s an absolutely new reconfiguration of how manufacturing works. It affords companies the flexibility to grow and innovate on their own terms. Xlaserlab believes the future belongs to companies that can unite super high precision with flexibility. And its modular systems are in such a way that they will enhance their collaboration.

These systems are more than a convenience for up-and-coming manufacturers. They reduce the amount of energy used, save floor space, and need fewer maintenance hours. They also have the added benefit of helping businesses to scale faster and be more efficient with their production. From laser wood engraving and right up to laser engraving metal, Xlaserlab ensures that no project is let down by accuracy or quality standards.

Both flexibility and sustainability are promised with Xlaserlab, which will become a key player in the coming of age of industry. With practical, affordable upgrades across its platforms, the company helps all-sized businesses enhance their lines with minimal investment and downtime.

About Xlaserlab

Xlaserlab is the world’s largest smart laser solution manufacturer that offers precision instruments for many applications. Its modular laser engines are engineered for performance, efficiency, and flexibility. From laser engraving wood to cutting acrylic, etching metal, they have a wide range of machines that provide the best results from both large-format machinery and smaller desktop devices. It is a maker that stands behind its product by continually delivering high-quality, performance-driven random orbit sanders with true design innovation and purposeful developments for decades.