You don’t have the time to spare, especially if you’re managing equipment, assets, or a facility. Skip a maintenance chore, and suddenly, you’re slogging through costly repair bills, facing labor problems on the job site, and dealing with downtime that wasn’t built into the schedule. That’s why systems are needed. A maintenance management software solution that allows you to tackle these problems before they even begin raising their ugly heads. But is that possible? Let’s talk about it.

The Issue with Reactive Maintenance

Something (a machine, some equipment, or a tool) breaks, and suddenly, everyone’s scrambling. You’ve been there, haven’t you? The technician can’t locate the last service record. The parts aren’t in stock. So, operations are halted. In the meantime, it’s both your budget and your sanity that take a good beating. That’s where preventative maintenance software comes in.

Dependence on “fix-it-when-it-breaks” is a surefire path to wasting time, money, and patience. It’s stressful, inefficient, and unnecessary. Why deal with these hassles when easy solutions are available?

Speedier Repairs, Fewer Disruptions

Even with preventive maintenance, things still break. The difference is that when they do, you’re prepared. With digital logs, repair history can be distinguished from all other data. The technician can see what has been done in the past. They know what components were replaced, what problems were reported, and what fixes were made. This reduces diagnosis time by a good margin.

It’s also easier to keep track of parts. The software signals if the part is available. If not, you can reorder in a minute—no more writing long emails or searching for conversation threads that show “who had it last.”

This will save you many hours! Multiply that by teams or sites, and the time savings will increase exponentially.

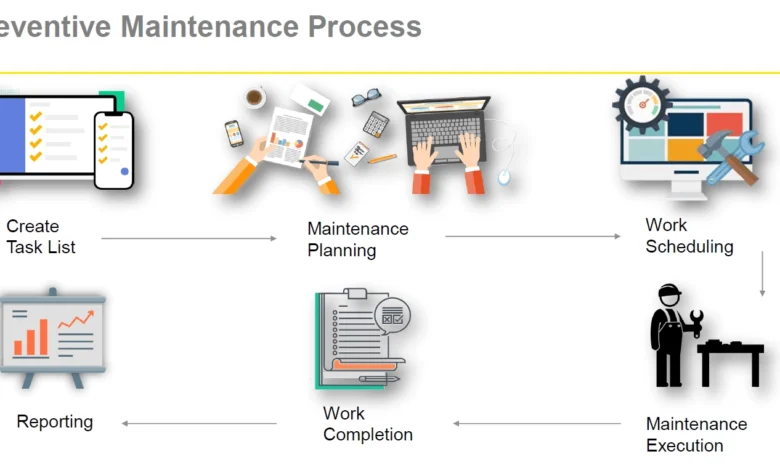

Automation for Things People Shouldn’t Be Handling

You don’t have to remember every task, mark calendars, or send manual reminders. The software does all of that. It also schedules work orders autonomously and notifies your team. It also monitors inventory and lets you know you’re running low.

In addition, preventive maintenance software is a handy inventory management tool you can carry in your pocket. Everything’s logged. Everything’s tracked. You know everything about inventory due dates, so no more guesswork. This way, your team is ahead of the curve. Equipment stays healthier. And you finally get to stop being the firefighter and be the proactive one.

Less Paper, More Clarity

Aren’t paper-based systems a disaster many times? Handwritten notes get lost. Files don’t get updated. In stressful situations, you’re scrambling to find a maintenance record that was supposed to be in that binder but isn’t.

Preventive maintenance software eliminates this mess. Everyone works on the same system, updates information, and gets real-time updates. Technicians can pull up records from their phones, and managers can access reports in seconds. And audits? They become painless. It’s all documented nicely, neatly, and in one place.

Say Goodbye to Backlogs and Hello to Efficiency

Backlogs arise from tasks falling through the cracks. More commonly, they’re the product of bad visibility and bad timing. Preventive maintenance software keeps you on top of your workload. It assigns priorities on time based on previous work and machine conditions. So, your team is not responding to chaos but dealing with an orderly queue.

It also shows you trends. The system tells you if a machine always malfunctions and requires technicians to solve the problems. This way, you act on solid evidence. Such clarity ensures fewer breakdowns, quicker repair times, and more intelligent use of resources.

Saves Time Now, Saves Stress Later

Here’s the big picture: This isn’t only about saving a few hours. It’s all about taking back your workday and sleeping better because you know your assets are not ticking time bombs. It’s preventing surprise failures and hurried fixes. Preventive maintenance software helps you do work that matters; it’s strategic, thoughtful, and deliberate, not just urgent.

Plus, time savings add up quickly if you oversee a growing team or multiple sites. Suddenly, you’re not overwhelmed with to-dos. You’re the captain of pleasantly humming operations.

Final Thoughts

Maintenance isn’t appealing, but it is essential. It is time to upgrade if you still use sticky notes and spreadsheets or make gut-instinct decisions. Time is money. But, more importantly, time is peace of mind. And preventive maintenance software gives you both.

So, the question you have to ask yourself is—what would you do with an extra ten hours a week? Because, with the proper setup, it’s not just a dream but a regular Tuesday.