Manufacturing Execution Systems (MES) have long been positioned as the digital backbone of modern factories. They orchestrate production workflows, enforce quality checks, synchronize machines with enterprise systems, and provide real-time visibility into operations. Yet despite their strategic importance, MES deployments continue to suffer from a persistent, under-discussed challenge: configuration.

Configuring an MES, particularly modern platforms such as SAP Digital Manufacturing, remains a highly manual, expert-driven process. Setting up routings, work centers, machine integrations, quality checkpoints, and master data can take weeks. Errors introduced during configuration often surface only after go-live, leading to rework, production delays, or inconsistent data across ERP, PLM, and shop-floor systems. As manufacturers scale across plants, products, and geographies, these configuration bottlenecks become a structural constraint on digital transformation.

Recent advances in Generative AI and large language models (LLMs) indicate a new direction, transforming the MES setup from a trial-and-error process into a guided, data-driven capability.

Why MES Configuration Has Become the Hidden Constraint

Most manufacturing leaders recognize the value of MES but underestimate the complexity of setting it up correctly. Configuration is not just about filling fields in a UI. It requires:

- Translating unstructured inputs (process documents, SOPs, emails, spec sheets) into structured system data

- Applying domain-specific rules that vary by plant, product, and regulatory context.

- Ensuring consistency across interconnected systems (ERP, MES, PLM, SCADA)

- Anticipating downstream effects of configuration decisions

Traditional approaches depend on static templates, documentation, and a limited group of subject matter experts. These methods lack scalability. Templates fail in the presence of edge cases, documentation becomes outdated, and experts create bottlenecks.

This leads to a recurring pattern of extended setup cycles, repeated errors, significant dependence on tacit knowledge, and delayed realization of MES value.

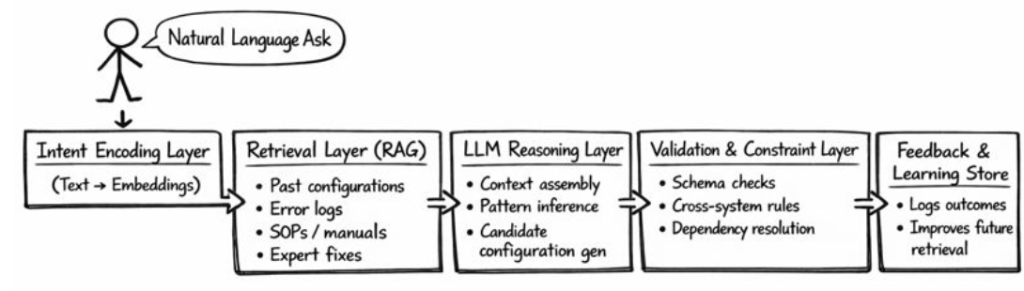

Enter Generative AI as a Configuration Co-Pilot

Large language models are highly effective at processing unstructured information, identifying patterns, and generating context-aware recommendations. Applied to MES configuration, these capabilities facilitate a transition from manual rule-following to intelligent assistance. Rather than requiring users to possess in-depth system knowledge, an LLM-driven approach enables them to articulate their needs in plain language:

- “Add a new work center for assembly line B.”

- “Create a routing with quality checks after operation 20.”

- “Why is this machine not linking to the work center?”

Behind the scenes, the model maps these natural language requests to valid system configurations by learning from historical setups, system logs, configuration rules, and expert-approved patterns.

Importantly, this approach does not constitute unrestricted automation. The model functions within the boundaries of MES schemas, validation rules, and established best practices. It proposes configurations, identifies inconsistencies, and provides explanations for configuration choices before implementation.

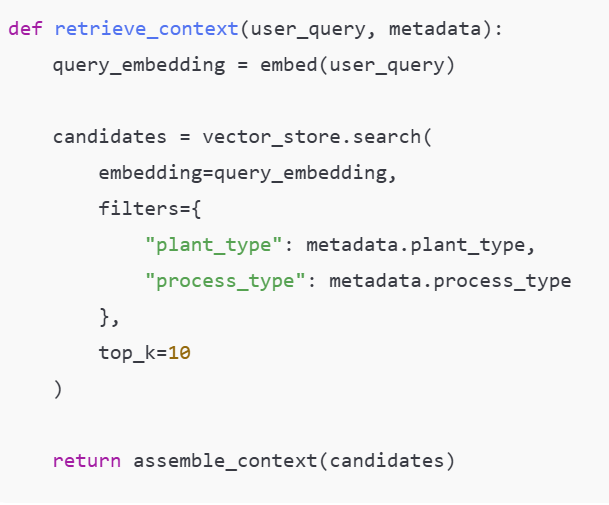

Turning Past Experience into Scalable Intelligence

A significant advantage of this approach is its ability to leverage existing factory knowledge, which is often difficult to operationalize. Every MES rollout generates a wealth of data: successful configurations, failed attempts, error codes, support tickets, and expert fixes. Traditionally, this knowledge remains fragmented across documents, emails, and individual memory. LLM-based systems can ingest this material and convert it into a reusable knowledge layer. When a new configuration request appears, the model can:

- Identify similar historical cases.

- Recommend settings that worked previously.

- Highlight common failure points.

- Surface overlooked system features relevant to the task.

As a result, each configuration setup informs subsequent ones, allowing configuration knowledge to accumulate rather than dissipate.

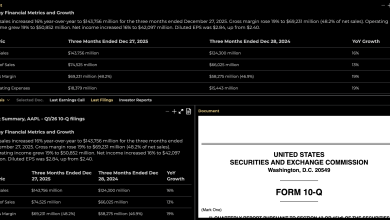

Measurable Impact on Speed, Quality, and Adoption

Empirical results from real-world testing show that model-assisted MES configuration can deliver tangible gains:

- Setup time reductions of ~30–60% for common tasks

- Higher configuration accuracy, with correct setups increasing from roughly 60% to 90% in controlled comparisons.

- Fewer user errors and rework cycles, especially among less experienced users.

- Increased feature utilization, as users discover capabilities that they previously avoided due to complexity.

Notably, user confidence increases when the system provides explanations for recommended configurations. This transparency fosters greater willingness among engineers and planners to experiment, test changes, and adopt standardized approaches. This represents a subtle yet critical shift, transforming MES from a rigid system requiring cautious handling into a collaborative platform that supports informed decision-making.

Bridging the Skills Gap on the Shop Floor

Manufacturing faces a well-documented skills challenge. Experienced MES architects are scarce, while new engineers and IT staff often require months to become productive. LLM-driven configuration support acts as an embedded mentor.

New users can learn through practical engagement, such as asking questions, receiving step-by-step guidance, and observing how configurations correspond to actual system behavior. Experts, in turn, allocate more time to architecture, optimization, and governance and less to repetitive setup tasks.

This redistribution of effort does not remove the necessity for human oversight. Final approval, complex edge cases, and strategic design continue to require expert involvement. However, the overall system becomes more resilient and less reliant on a limited number of individuals.

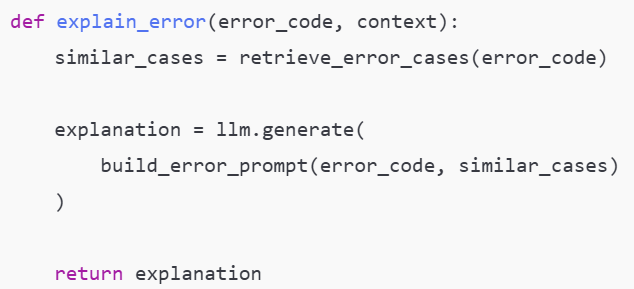

From Reactive Troubleshooting to Proactive Validation

Another overlooked benefit is error handling. MES error messages are notoriously opaque. Decoding them often requires expert intervention and multiple support cycles.

By correlating error codes with past incidents and fixes, an LLM-based assistant can translate system errors into actionable guidance:

- What caused the issue?

- Where to look in the configuration?

- How similar problems were resolved previously?

This approach transforms troubleshooting from a reactive process into a guided resolution workflow, thereby reducing downtime and support demands.

What this means for Digital Manufacturing. The implications extend beyond MES configuration efficiency. Generative AI introduces a new interaction model for manufacturing systems, in which complexity is managed through intelligence rather than reliance on documentation.

For manufacturers pursuing Industry 4.0 or smart factory initiatives, this approach offers several strategic advantages:

- Faster global rollouts with more consistent configurations

- Reduced dependence on scarce specialists

- Improved data quality across integrated systems

- Greater agility when processes, products, or regulations change.

Over time, these principles may be applied beyond MES to ERP configuration, integration mapping, and operational decision support.

Proceeding with Realism

It is important to be clear-eyed about limitations. LLMs do not “understand” manufacturing in the same way humans do. They infer patterns. Poor data, outdated documentation, or ungoverned model updates can lead to incorrect recommendations. Strong validation layers, expert review, and continuous feedback loops are essential. When applied responsibly, generative AI serves as a force multiplier, rather than a substitute for engineering judgment.

The Path Forward

MES has consistently promised operational visibility and control, yet usability at scale has remained elusive. Embedding generative AI into configuration workflows enables manufacturers to address this gap.

The future of digital manufacturing will be shaped not only by advanced machines or faster networks, but by systems that enhance human productivity. Intelligent configuration assistance represents a tangible step toward this goal, transforming the burden of MES setup into a strategic accelerator. A study in the IJAM Journal shows that LLM-driven MES configuration offers a clear way forward.

—Authored by Prahlad Chowdhury, Managing Solution Architect, Fujitsu America Inc