Real progress AI has been recording across sectors and domains, PCB routing is no exception of such tremendous improvements. Employing AI to power and facilitate the complex yet proven workflow of identifying electrical connectivity between parts boosts methodical assembly throughput and precision within high volume PCB design. Our PCB is one of the leading representatives when it comes to such AI cohesive work flow. For more information about high volume pcb, visit their website.

The Role of AI in PCB Routing

AI systems utilize advanced algorithms to analyze design rules, component placements, and routing constraints. By doing so, they generate efficient routing solutions that ensure optimal performance and reliability. This automated approach not only reduces the time required for PCB design but also minimizes the potential for human error, leading to higher quality products.

The Role of AI in PCB Routing

AI systems utilize advanced algorithms to analyze design rules, component placements, and routing constraints. By doing so, they generate efficient routing solutions that ensure optimal performance and reliability. This automated approach not only reduces the time required for PCB design but also minimizes the potential for human error, leading to higher quality products.

Key advancements include:

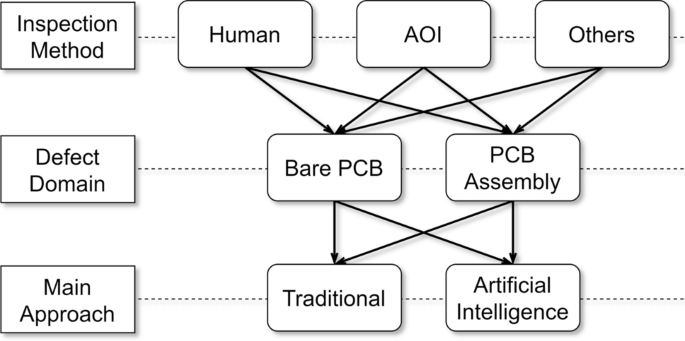

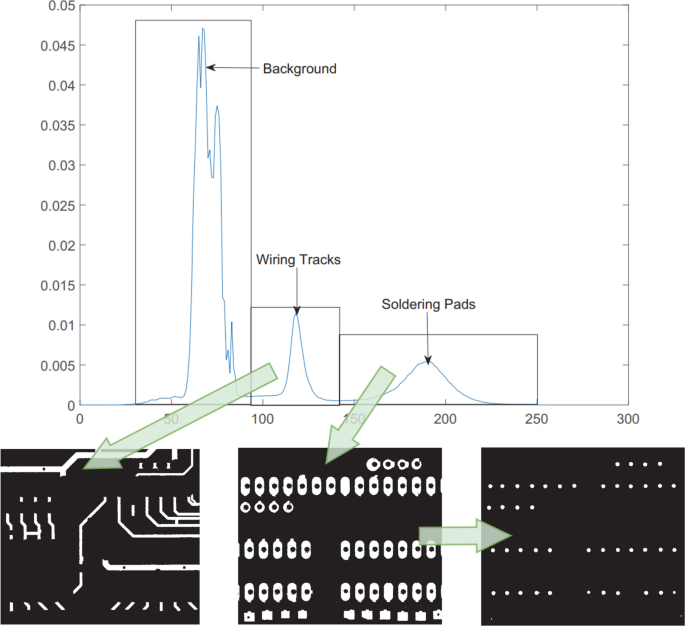

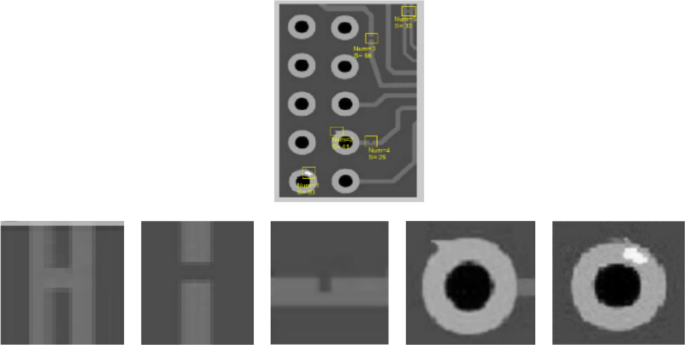

- Improved Inspection Accuracy: AI based inspection systems are more effective in identifying flaws in PCBs and are much more accurate than the manual forms of inspection that may involve a human eye which has a certain percentage of error because of the limitations in human eyesight and they also possess machine learning algorithms that increase from data gathered from previous inspections.

- Enhanced Defect Detection: AI-based systems can reportedly recognize and categorize more kinds of defects, including those that are less conspicuous or may be unnoticed by human inspectors or by automated systems of less complex AI.

Benefits of High Volume PCB Assembly for AI Projects

- Rapid Prototyping: AI-driven PCB routing enables quick iteration and testing of designs, which is crucial for the fast-paced development cycles in AI projects.

- Cost-Effective Solutions: High volume PCB assembly allows for the production of small batches, reducing waste and lowering costs for AI startups and researchers.

- Custom Designs: The flexibility of high volume production means that custom PCBs tailored to specific AI applications can be created efficiently.

Key Features of AI-Enhanced PCB Assembly

- Advanced AI Algorithms: Automate complex routing processes, ensuring optimal electrical connections and efficient use of space.

- High Precision: AI enhances accuracy, reducing the likelihood of errors and improving the overall quality of PCBs.

- Scalability: From small prototypes to larger production runs, AI-driven PCB assembly can scale to meet the needs of various AI projects.

- Cost Efficiency: High volume assembly reduces costs, making high-quality PCBs accessible to smaller projects and startups.

- Comprehensive Support: From initial design consultation to final product delivery, AI integration ensures a seamless experience.

Why is AI-driven PCB assembly crucial for AI designs?

The adoption of AI in the flow of manufacturing processes required within the assembly of PCBs has significantly transformed how printed circuit boards are produced. This characteristic is particularly valuable in AI, as the nature of the input data and the result highly depends on the accuracy and stability of the method used.

Quote from a Company Spokesperson: Incorporating AI into our PCB assembly system facilitates production of very efficient and accurate outcomes, which are especially useful in cases where precision is a critical factor, such as in AI equipment necessitation, according to Lee, the CEO of OurPCB- an industry-leading provider of PCB assembly solutions.

Q1: How does AI improve the quality of PCB assembly?

AI enhances PCB assembly by automating complex routing processes, increasing precision, and minimizing errors.

Q2: What are the benefits of high volume PCB assembly for AI projects?

High volume PCB assembly offers rapid prototyping, cost-effective solutions, and the ability to produce custom designs tailored to specific AI applications.

Q3: Can AI-driven PCB assembly handle large-scale production runs?

Yes, AI-driven PCB assembly services are scalable, accommodating both small prototypes and larger production runs.

Q4: How does AI-driven PCB routing work?

AI algorithms analyze design rules, component placements, and routing constraints to generate efficient and accurate routing solutions.

Q5: What makes AI-driven PCB assembly a reliable choice for AI developers?

The integration of AI, experienced teams, and a commitment to quality make AI-driven PCB assembly services a trusted provider for AI developers.