Warehouses can no longer be considered simply as storage facilities. In today’s interconnected world, warehousing is key to an efficient supply chain, bridging the gap between supply and demand. It’s a vital part of ensuring the consumer gets the product they ordered in their hands on time and without damage.

Conceptually, the journey of AI ( artificial intelligence) spans over 60 years oscillating between popularity and obscurity within scientific circles. AI as the real-world phenomenon we witness today is propelled by several breakthroughs in underlying algorithms, infrastructure with high-performance edge computing and data availability – driving its commercial traction in 2024.

It is therefore no surprise that AI has found its place in various industries from finance and healthcare-related industries, all the way to manufacturing and supply chains. Its seamless integration with existing technologies is driving the widespread adoption we are witnessing today.

The growth of warehousing

Where AI has been used extensively in enterprises across the globe, one of the areas that are seeing a resurgence and re-imagination of how things are done is the supply chain and warehousing industry. Where the sector has long been implementing automation from a hardware point of view, it is now seeing a rise in the amalgamation of robotics and AI. Next Move Strategy Consulting indicates that by 2030, the warehouse robotics market will reach just under $16 billion. Further, 77% of organisations are serious about automated warehouse systems and mapping a plan to maximise data-driven performance.

Since the pandemic, eCommerce has taken an even stronger foothold in terms of how we consume goods and as consumers we expect to receive our goods as quickly as possible, without fuss. Warehousing plays an essential part in supply chain management and the global economy. Thanks to eCommerce, demands on warehousing are growing like never before. As retailers add more inventory to meet consumer demand, the need for distribution centres and effective management of space skyrockets. Additionally, many manufacturers are diversifying their supply chains, creating opportunities for third-party logistics providers. This also increases the need for automation, people and advanced technologies like AI.

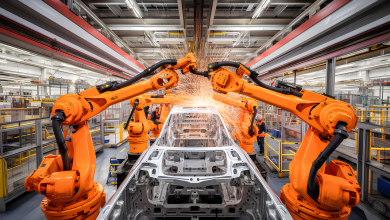

How robotics and AI go hand in hand

The global warehouse industry has been over-reliant on manual processes and irregular data snapshots which are outdated by the time they are entered into a warehouse management system (WMS). Today’s businesses need real-time data and visibility to obtain an accurate picture of their business performance and allow them to optimise their processes and space. If companies lack visibility into areas such as stock accuracy, or the movement of goods, they are less likely to operate in a cost-efficient way.

Thanks to the technological advances made in robotics and AI-powered visibility platforms, warehouse operators can now bring real-time visibility into the frame, and boost both efficiency and productivity. Allowing operators to digitally simulate the physical state and behaviour of the warehouse environment, unlocks greater visibility over stock and forecasting trends. It also allows testing scenarios in the digital environment before implementing them in the real world, to ensure changes do not disrupt intricate workflows and processes.

AI enhances warehousing capabilities

It has always been a challenge for retailers to get the right product in the right place at the right time but this has intensified in recent years due to geopolitical tensions, supply chain shortages, changing consumer preferences, and increased competition. As such, precision and efficiency are paramount.

Despite this, Gartner has reported that 60% of leaders revealed their supply chains have never been designed for resiliency. Last year, IHL Group estimated the combined cost of stock mismanagement at $1.77 trillion. This signals a greater need for streamlined processes that optimise efficiency. This can be achieved using AI.

Below are some of the key ways in which AI enhances warehouse performance.

Greater accuracy

AI can be implemented to automate routine tasks such as counting stock, saving time and minimising human error. By using AI-powered technologies, organisations can start to gather up-to-date real-time data that will help them drive their businesses forward through a better understanding of potential bottlenecks.

The amount of data in warehousing can feel neverending. That is why data processing is critical for leveraging AI in warehouse management. Quickly gaining an understanding of the movement of goods, space utilisation and most importantly, accuracy on the location of goods will allow operatives to spend time on more strategic tasks and the data that is being generated can be used to understand where the next business opportunity lies.

Optimising space

Warehouse space does not come cheap – for every £1 billion spent online, an additional 775,000 sq ft of warehouse space is needed. However, warehouse space allocation is often inefficient with underused areas going unnoticed.

AI-driven solutions can help in a variety of ways. Firstly, through advanced space mapping which uses AI algorithms to conduct comprehensive warehouse space mapping. It enables real-time data analysis on available space and inventory levels. AI can use the demand trends and storage capacity to generate optimal warehouse layouts.

Static storage arrangements waste space and cause difficulty in retrieving items. By implementing AI-powered dynamic inventory placement systems, warehouse managers can assess inventory movement patterns and change storage locations where needed. High-demand items can be accessed easily, while less popular items are stored elsewhere, maximising the space available.

Another key use case of AI is through predictive analytics, which forecasts future demand and storage needs with unprecedented accuracy. By analysing previous data and identifying patterns, AI algorithms can predict future fluctuations, enabling better planning for peak seasons.

Augmenting the human workforce

Like many others, the warehousing and logistics industry is no stranger to skills shortages. This has encouraged businesses to explore how AI can be harnessed to overcome these issues. It is important to note that implementing AI requires buy-in from teams and clarity regarding how it will be used.

While there are concerns that automation threatens human jobs, it is not as simple as that. AI can enhance human capabilities, rather than outright replacing them. For example, automating repetitive tasks like inventory management enables employees to engage in more challenging tasks and use the data to help improve decision-making. This can boost productivity as it has the potential to offer team members more strategic roles within logistics.

Additionally, safety is critical in the warehouse environment and AI can ensure reliable risk management. AI-powered processes can improve the health and safety in warehouses as tools can monitor for hazards as well as issues in any machinery, signalling to workers when there are risks.

The warehousing industry is expanding rapidly and shows no signs of slowing down. With that comes increased complexity, competition and the need for precision and accuracy. With the advancements AI offers, the industry will continue to innovate to keep pace with these challenges. AI offers visibility like never before, enabling us to operate safer, more transparent and more efficient warehouse management.