How vertical integration and AI-driven analytics are changing the economics of greenhouse gas detection

Methane is the second most significant greenhouse gas contributing to climate change, with a global warming potential roughly 80 times that of carbon dioxide over a 20-year period. The gas escapes from oil and gas operations, landfills, and agricultural facilities, often undetected until satellite measurements reveal the scale of the problem. Reducing methane emissions represents one of the fastest pathways to slowing global warming, but reduction requires detection, and detection at scale has remained prohibitively expensive.

The challenge is not just technological capability – sensors exist that can detect methane with high precision. The real challenge is economics and intelligence. Existing solutions cost enough that operators deploy them sparingly, creating gaps in coverage that allow emissions to go undetected for extended periods. Even where sensors are deployed, the sheer volume of data they generate demands artificial intelligence to transform raw readings into actionable insights. Without AI-powered analytics, operators are left sifting through noise, unable to distinguish routine fluctuations from genuine emission events.

A landfill might have monitoring at its perimeter but lack the dense sensor network and intelligent software needed to identify exactly where leaks originate. An oil field might detect large releases but miss the cumulative impact of dozens of smaller ones that only pattern-recognition algorithms can piece together. The convergence of affordable sensor hardware and AI-driven data processing is now poised to close these gaps.

Lyten, a materials technology company based in San Jose, is approaching this problem from first principles. Rather than optimizing existing sensor designs, the company is leveraging its proprietary materials platform to fundamentally change the cost structure of methane detection. The vision is to make sensors affordable enough to deploy in dense networks, providing AI-enabled continuous monitoring rather than periodic sampling.

The Vertical Integration Advantage

Mr. Ajay Vemuru joined Lyten as Senior Director of Business Development in 2025, bringing experience accelerating customer developments in a range of emerging markets at Spirent Communications, where he grew the positioning business across the Americas. His mandate at Lyten is to bring the company’s sensor technology to market in the oil and gas and waste management sectors.

“The problem at these industries is there is no continuous monitoring that is both reliable and low cost,” Mr. Vemuru said. “Existing solutions force operators to choose between accuracy and affordability. Our vision is to eliminate that tradeoff.”

Lyten’s approach differs from competitors in a fundamental way: vertical integration. The company manufactures the advanced materials that form the sensing elements, designs the sensors themselves, and develops the AI-powered software that processes their outputs. This control over the entire technology stack – from materials to machine learning algorithms – provides cost advantages that companies assembling sensors from third-party components cannot match.

“Because we make the material, we make the sensors, everything is vertically integrated,” Mr. Vemuru explained. “That means we have much more control over the cost structure and overall performance. If we can solve the cost problem, we can deploy quality high-density sensor networks. That changes everything about how operators can manage their emissions.”

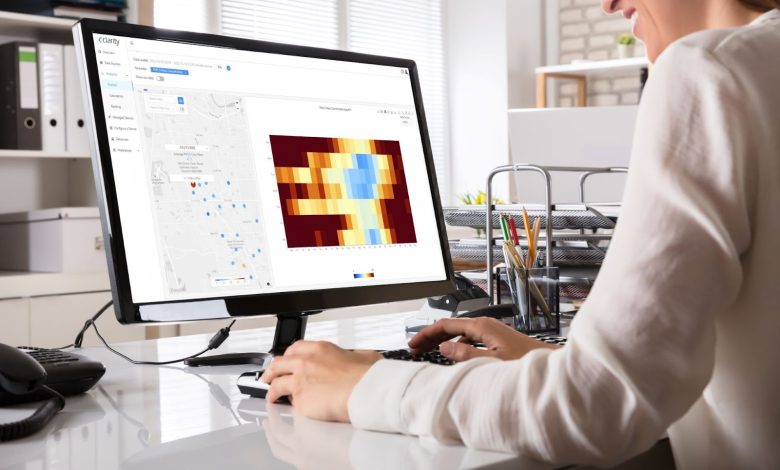

Where AI becomes critical is in what happens after the sensors collect data. Dense networks of low-cost sensors generate massive streams of environmental readings. Lyten’s software platform applies artificial intelligence and machine learning to this data – detecting anomalies, filtering out environmental noise, correlating readings across multiple sensors, and pinpointing the precise location and magnitude of emission sources. This intelligent layer transforms raw sensor data into real-time, actionable alerts that operators can act on immediately.

Regulatory Tailwinds

The timing of Lyten’s market entry coincides with a global tightening of methane regulations. New requirements in Europe mandate more rigorous monitoring and reporting of methane emissions from energy operations. Canada introduced new regulations in December 2025. In the United States, the EPA’s methane rules for the oil and gas sector impose escalating requirements through 2026.

These regulations create both compliance requirements and economic incentives. Operators who can demonstrate lower emissions may face reduced regulatory scrutiny and qualify for preferential treatment in carbon markets. Those who cannot may find their products disadvantaged as purchasers increasingly factor emissions intensity into sourcing decisions.

“Anytime there is a new regulation around climate change, we fit really well,” Mr. Vemuru said. “The regulatory environment is creating demand for exactly what we are building. Operators need continuous monitoring, and they need it at a price point that allows comprehensive deployment.”

From Detection to Action

Lyten’s initial focus is on the United States and Canada, markets where regulatory frameworks are established and enforcement is active. The company’s sensors are designed for deployment across oil and gas facilities and waste management sites, with the goal of providing operators with AI-driven continuous visibility needed to identify and address emissions sources rapidly.

“Our vision is to give operators all the tools they need to limit methane emissions,” Mr. Vemuru said. “That means detection, localization, and alerts. When you have a dense network of low-cost sensors powered by AI analytics, you can pinpoint exactly where emissions are occurring and respond immediately rather than discovering problems weeks or months later.”

The climate monitoring market remains competitive, with established players and well-funded startups pursuing various approaches to the methane detection challenge. Satellite-based monitoring offers broad coverage but limited precision. Drone-based surveys provide detail but require active deployment. Ground-based sensors offer continuous monitoring but have historically been too expensive for dense deployment. AI is the connective tissue that makes each of these approaches more powerful – and for ground-based networks, it is the key to turning affordable hardware into an intelligent monitoring system.

Whether Lyten’s vertical integration strategy can deliver AI-enhanced sensors at price points that change deployment economics will determine its success. Mr. Vemuru’s track record of launching new solutions targeted towards automotive and robotics market suggests the commercial execution capability is in place. The opportunity is substantial for whoever solves the affordability challenge. The potential to reach new and evolving markets with affordable, AI-powered technology could transform how industries approach emissions management. The climate impact could be even greater.