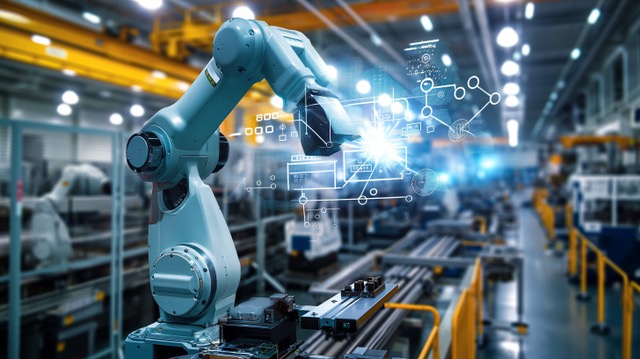

Global robotics growth is exploding – with a record-breaking 4.2 million robots being used to assemble computers and mobile devices, package millions of goods, inspect final products for quality control, and monitor performance of production lines across industries today. That number is expected to more than triple in the next five years to 16.3 million in 2030, with the value of industrial robot installations advancing beyond today’s all-time high of US$47.8 billion to over $211 billion by 2034.

Manufacturers anticipate leveraging more technology in their operations moving forward, yet deploying new technologies is still the number one challenge facing these businesses. According to an ABI report, about 86% of firms say that staff do not have the skills to utilize new technologies and 90% of companies say they don’t have the time to conduct the necessary planning to scale innovations.

Most industrial robots in manufacturing today are rigidly pre-programmed for repetitive, single tasks in controlled settings and optimizing productivity comes at the expense of flexibility, time and money. These robots are unable to dynamically adapt to real-time deviations or easily accommodate changes and fall short in its ability to respond to small changes in production tasks or variables like adding new parts or additional instructions.

Emerging AI-enabled robotic software is changing this dynamic by democratizing frameworks for users and alleviating many of the traditional automation challenges. By enhancing a robotic system’s capabilities to think like humans and adapt and respond to the changing world in real-time, robotic automation will rapidly advance and transform manufacturing.

Human-Like is a Reality

While some robotics systems are smart enough to see and act within defined boundaries, they’re often limited in perception, reasoning, dynamic motion planning and task creation to execute multiple actions in a timely manner.

Traditional robotics programming is time consuming and rigid, requiring detailed step-by-step instructions to complete a task. Programming industrial robots typically requires the use of proprietary tools and programming protocols, making it cumbersome and cost-prohibitive to update or change. Reprogramming these robots takes significant time and resources, often requiring internal or third-party robot programmers. This means longer downtime for assembly line changes, impacting production and go-to-market speed.

According to ABI, emerging AI-enabled robotic software that also accommodates low-code/no-code robot training environments enable the rapid instantiation of automation workflows that traditionally couldn’t be automated due to the complexity of the process or environment. This autonomy software empowers robotic automation to function more like humans in terms of flexibility and adaptability to changes. The software takes the reliability and repeatable characteristics of machines and combines them with human-like ability to observe, learn, reason and act with remarkable agility, emulating a human sensorimotor approach to enhance performance and automate complex tasks.

By combining state-of-the-art AI techniques — for example perceptual object recognition and autonomous generation of complex plans for task execution — with precise, yet adaptive, robot manipulator and end effector control, these new software platforms provide performance flexibility for trained tasks and task flexibility via rapid task refinement or learning of novel tasks based on worker demonstrations or chatbot instruction inputs.

AI-enabled, closed-loop autonomy software empowers robots to perceive variations or changes in the real-world environment and learn to adapt to tasks dynamically. By employing edge-AI to enable human-like robotics perception, robots can immediately self-correct in response to unexpected events, perform a large range of tasks and safely work within production lines. With this approach, robots can now comprehend variation, operate at the edge and learn new tasks to thrive in diverse production lines all without cloud connectiveness.

Workforce Flexibility

AI-enabled software fosters workforce flexibility and productivity, while increasing job safety and minimizing human risk.

Traditionally, automation is programmed for one robot to complete a limited number of simple, repetitive tasks; altering these configurations might require calling in highly skilled engineers to reprogram a robot for another task, adding extra time and money.

However, cutting-edge AI software with low-code, no-code task training capabilities enables even a line worker to train the robots quickly and inexpensively to support multi-task production lines and reducing the need for specialized engineering teams. They can reprogram and retrain the robots themselves to adapt to unexpected or changing variables of a line in less time, shorten deployment time and reduce costs overall. By allowing existing staff to program robots more efficiently, this flexibility in manufacturing improves margins.

Implementing AI-software affords smoother, faster and more reliable robotics automation — even in unstructured and cloudless environments — with lower costs from equipment damage and worker claims. Workers previously doing dirty, hazardous jobs can now shift into instructive and training roles in safer environments, leaving the robot to do the dangerous, labor-intensive work.

Automobile manufacturing is a good example of how an unstructured environment can benefit from AI-enabled closed-loop autonomy software. Part of the assembly at large automobile manufacturers involves kitting and sequencing multiple parts for a variety of car models. Automating the kit assembly process to accommodate a high-mix production model means ensuring not only accuracy but also maintaining just-in-time speed. Such orchestration is difficult to automate because it requires sophisticated planning, human intervention and high programming costs.

With AI-enabled closed-loop autonomy software, the kitting, sorting and sequencing process can now be automated to be more adaptable to change and variability. A user-friendly robot training app enables a line worker to set up a new task quickly with no coding experience needed. Once trained, the robot can autonomously execute the task with minimal downtime or human intervention. This frees up human resources and gets them to shift focus to more important aspects of the business.

Expanding Operations

Costly robotics and limited floor space often hinders small or mid-size manufacturers from using large or multiple robotic systems. Emerging AI-enabled autonomy software, however, is opening new, growth opportunities in traditionally challenging locations and giving smaller and medium-sized companies the opportunity to compete with their larger peers.

The versatility of these software platforms means it can be used to automate robotics in different robot types, factory floor sizes and industries. Edge AI-based closed-loop autonomy software requires less data to train models and manufacturers don’t need cloud connectedness which is often associated with huge amount of data transfer, high costs and security issues.

This increases the flexibility of robotic systems by enabling a single robot to perform multiple functions, thus reducing the space needed for manufacturing operations. Shifting robots from single work tasks to multi-purpose tasks means there is no need for multiple robots to complete tasks — which also reduces the hardware investment.

Higher ROI

AI-enable closed-loop autonomy software overcomes the critical barrier to high return on investment (ROI) of typical robotic automation adoption by focusing on reliable, safe and productive flexibility while supporting demanding enterprise requirements.

Software solutions that are hardware agnostic allows manufacturers to leverage a range of existing robotic platforms or cross-vendor purchases. This bridges the automation gap and boosts efficiency and scalability across different manufacturing settings, making the workflow automation more agile and driving more autonomy into operational deployments.

There are myriad benefits of implementing AI-enabled, closed-loop autonomy software:

- Speed up real-time performance

- Respond to human input and feedback in hours instead of days

- Protect proprietary information from potential leakage

- Improve skills of line workers to repurpose the tasks

- Promote efficient, cost-optimized operations with a better utilized workforce

Driven by closed-loop autonomy and advanced AI, existing robotics will accelerate in automation deployments and unlock new levels of efficiency and scalability in manufacturing. Soon, we’ll be creating a future where machines and humans work together seamlessly to tackle new challenges and growth opportunities.