Amidst a growing automation market and paroxysm around (hype)rautomation, the impact of automation scale grips the attention of the C-suite. Why is scale important?

The pandemic has shined the light on a basal enterprise need – resiliency. One way to achieve it is through automation. One component of an automation strategy is RPA. In the plethora of choices available to a business executive, finding the right set of technologies, piecing them together efficiently and driving operational efficiency and resiliency is more important than ever before.

“The need for business resilience drives focus, impacts spend & ALSO the definition of value. Value that is clearly aligned to the customer strategy is more important than ever before versus pushing bots or professing citizen development as the ultimate nirvana.”

DEBUNKING SCALE

Scale is one of the most misused word with automation (replaces ‘FTE reduction’ of years past). Customers struggle to define it, as often discussed in my independent customer only group called Vocal (Voice of the Customer in the Automation Landscape).

At times, scale is referred to as number of bots in an organization which while inaccurate for determining scale, is in fact a good determinant of adoption. Adoption today stands at approximately 80% of the 18k customers in the RPA market have less than 10 bots.

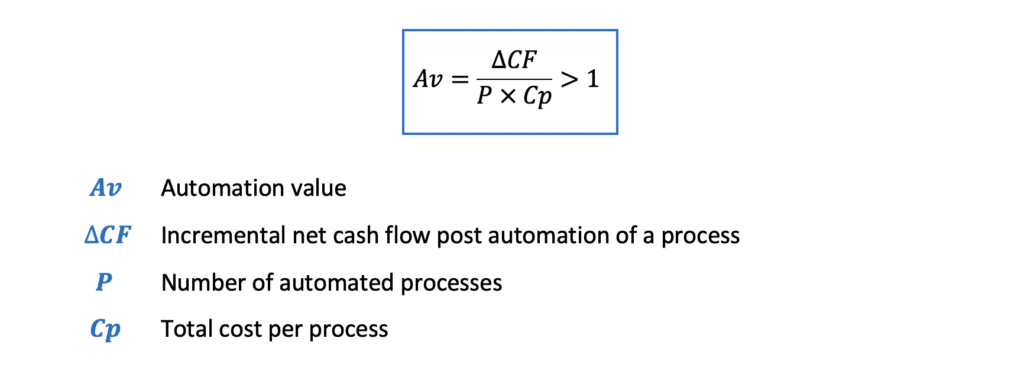

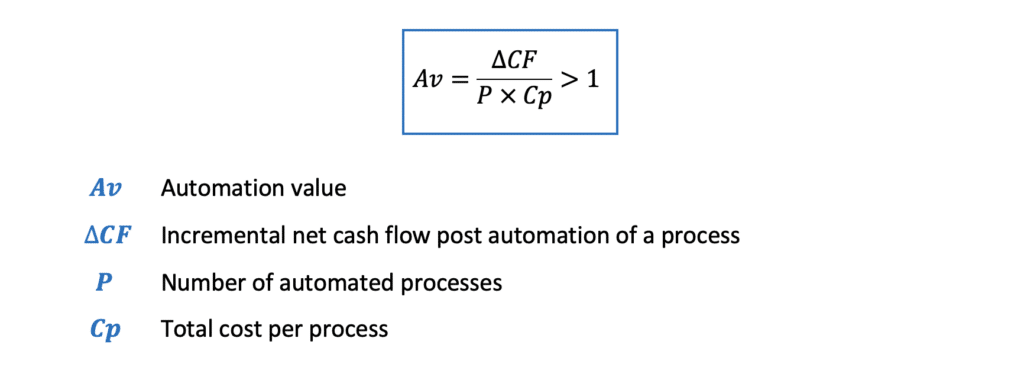

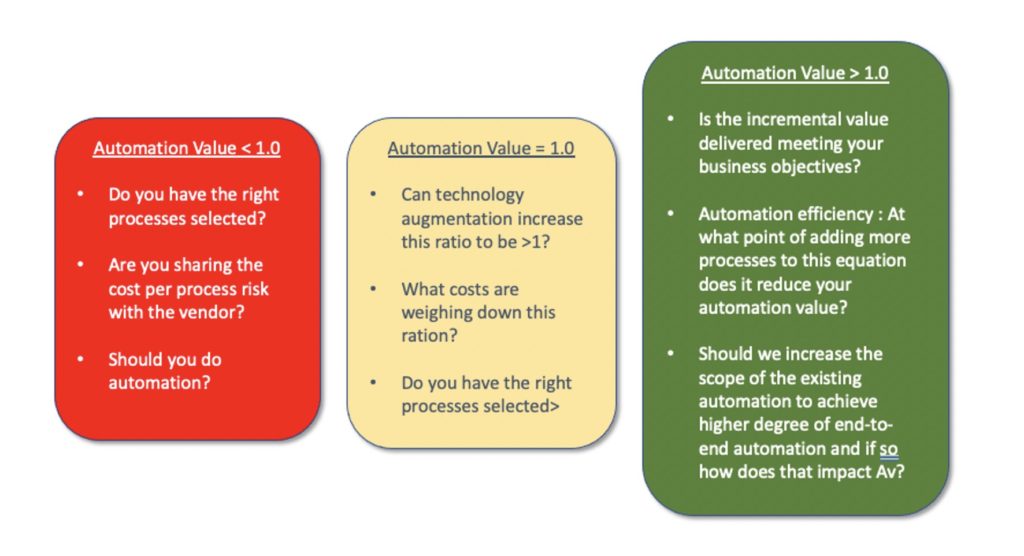

Scale is an outcome, not a solution. A better measure of scale would be Automation Value, defined below. But what are the components that drive a scaled automation program?

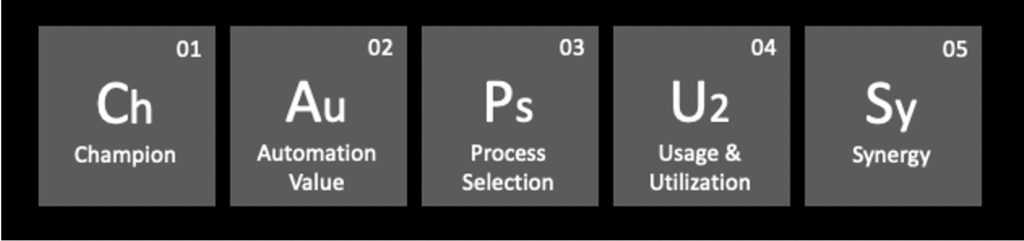

CAPUS and INTRODUCING AUTOMATION VALUE

Five key elements are required for a successful automation program.

Champion

All automation programs begin with a Champion who has the passion and ensures that every department & business unit is educated on the value of automation as a whole, not just the components like RPA, process mining etc. The champion therefore needs to have an understanding of infrastructure, security, governance, orchestration and integration and how to weave together various automation technologies to achieve your specific business objectives. The Champion often identifies, develops and nurtures the demand for automation, ensures flawless execution using a centralized of federated or hybrid COE model and is the fountainhead of driving a culture that embraces automation.

Automation Value

Often organizations struggle with ways to determine automation success. FTE reduction, hours returned back to the organization, number of bots, or derivative metrics (ie if this happened, must be because of the bots) are often considered. To determine true business value, one has to consider automation value.

More on automation value below.

Process Selection

A strong ‘processes to automate’ pipeline is essential for a successful program. Effective selection of highly repetitive, high value processes to automated and efficient intake, assessment and prioritization of the pipeline is critical for a successful automation program.

Usage and utilization

Deeply understand usage and utilization rates. Bot overload has caused some organization to put bots on the shelf and/or trade them back to the vendors for other services. Average utilization rate in the market was about 50% in 2018 and went up to 60% in 2019. While one should account for bot maintenance, if your bots are operating at a lower than 75 to 80% utilization, and it’s not by business design, you have to question why.

Synergy

IT and business have to come together. When implementing automation, IT is your friend and if you get it wrong it can be your implacable enemy. The CIO often owns the infrastructure necessary for the running and deployment of the robots so collaboration between IT and the business units needs to be confirmed on day one of the program.

Business AND IT synergy from the point of considering an automation program to day 1 of starting a project to jointly measuring success is of absolute importance for a successful program.

NUTS & BOLTS of AUTOMATION VALUE

Net savings generated post automation of a process can be considered as incremental cash flow, if determining the incremental cash flow is arduous.

Cost per process includes all costs associated with the automation. On average an automated process could cost anywhere between $10k to 25k depending on the complexity, including the license, infrastructure, CoE contribution, maintenance etc.

As an example, if you are running at a cost of say 10k per process, you would see a benefit in say mid-year 2 of that process (after POC, infrastructure purchases, environment setups etc.). To break even, your process has to return at a minimum of 410 hours in savings over this time of 18 months, just to break even if you consider a person making 75k/year handling that process.

This illustrates the need to pick the right processes but also sheds light on how to ask the right questions in your automation program. What is the true , at what point do you realize scale synergies ?, when should you add another process to automate in the mix? and how does that impact your Automation Value?

CAPUS and Automation Value represent a framework that allows you to evaluate the drivers and measure of success, of your automation program. It also offers a way to illuminate the the hidden costs and how those hidden costs impact your ROI – to have an effective conversation about the success of your automation program.

Scale is an outcome; its measure is Automation Value. Looking forward to your input on this and other questions that such a framework can raise, besides the ones I mentioned above.