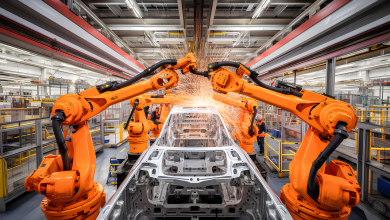

Efficient CNC machining isn’t just about advanced equipment or technical know-how. For engineers, product designers, and manufacturers, keeping machining costs under control without sacrificing quality is essential, especially in today’s competitive markets. Businesses in sectors like aerospace, automotive, and electronics consistently seek ways to maximize value for every dollar spent on precision components. XTJ CNC, understands this well and provides tailored services that focus on cost efficiency. Below, we clarify what drives CNC costs, practical steps for savings, and how to select the best partner for your next machining project.

Key Takeaways

- Cost-effective CNC machining requires understanding and managing factors like part complexity, material choice, tolerances, batch size, and lead time.

- Simplifying part designs and using standard tolerances can significantly lower CNC machining costs without compromising functionality.

- Choosing readily available and easy-to-machine materials, such as 6061 aluminum or engineering plastics, delivers budget-friendly CNC machining projects.

- Optimizing production processes—like batch processing, toolpath optimization, and reducing setups—unlocks additional cost savings in CNC machining.

- Selecting an experienced, transparent, and locally accessible CNC machining partner ensures sustained cost efficiency and reliable service.

Understanding CNC Machining Costs

CNC machining costs stem from a blend of factors, labor, equipment, materials, overhead, and setup time. The total expense doesn’t just reflect time on the machine: it covers programming, fixturing, tooling, inspection, and sometimes post-processing. Shops like XTJ CNC in Carmel, Indiana, structure quotes based on part complexity (think tight tolerances, intricate features), order volume, and material requirements. For smaller batches or prototypes, setup and programming usually dominate the cost, while production runs spread those costs across more parts, lowering per-piece pricing.

Labor rates, local economic factors, and equipment sophistication (such as 5-axis vs. 3-axis mills) also make a difference. Understanding these drivers helps buyers and designers make smarter choices early in the product development cycle.

Key Factors Influencing CNC Machining Expenses

Several factors can cause CNC machining prices to rise or fall:

- Part Complexity: The more complex the geometry, the more programming, specialty tooling, and precise fixturing needed. Multi-sided work and undercuts also increase cycle time.

- Material Choice: Harder or exotic materials like titanium cost more to machine than aluminum or plastics due to higher tool wear and slower cutting speeds.

- Tolerances and Finish: Tighter tolerances and fine surface finishes mean slower cutting, additional inspection, and possibly extra operations, all of which increase costs.

- Batch Size: Setups take time. Small runs absorb more cost per part, while large batches reduce unit cost through setup amortization.

- Lead Time: Expedite fees or tight deadlines push costs higher if overtime or prioritized scheduling is required.

XTJ CNC works closely with clients in Carmel and throughout Indiana to analyze these factors, offering clear estimates before work begins. Transparent communication upfront helps avoid budget surprises and ensures expectations are met.

Design Tips for Reducing CNC Machining Costs

Making smart design decisions at the outset delivers significant savings. Consider the following tips:

- Avoid Unnecessary Features: Limit complex curves, deep pockets, and undercuts unless essential for function. Simpler parts are faster and cheaper to machine.

- Standardize Tolerances: Only specify tight tolerances where necessary. General tolerance standards can be more cost-efficient.

- Simplify Assemblies: Where practical, combine multiple small parts into a single machined component to reduce individual setups and assembly steps.

- Consistent Wall Thicknesses: Design walls with consistent thickness: variable thicknesses are harder to machine accurately, increasing the chance of scrap or added inspection.

- Choose Stock Sizes Wisely: Match part size to standard bar, plate, or rod dimensions to minimize raw material waste and reduce time spent on roughing.

XTJ CNC can review customer CAD files and recommend modifications that achieve functional goals while keeping machining costs in check.

Material Selection for Budget-Friendly CNC Projects

Material costs affect both purchase price and machining time. Not every project requires aerospace-grade alloys or specialized plastics. Here’s a look at smart material choices:

- Aluminum: Frequently used for its machinability and strength-to-weight ratio. 6061 is widely available and affordable for most parts.

- Engineering Plastics: Acetal (Delrin) and nylon are easy to machine and suitable for many prototypes or low-stress components.

- Mild Steels: Good for structural parts requiring basic strength. Generally less expensive to machine than stainless or hardened steels.

- Standardized Materials: Using readily available grades simplifies purchasing and avoids delays, which can add hidden costs.

XTJ CNC helps clients evaluate their options, suggesting alternate grades or lower-cost materials during quoting to balance quality and budget. Carmel-area customers benefit from local material sourcing, helping keep freight expenses and lead times low.

Optimizing Production Processes for Cost Savings

The production process itself holds many hidden opportunities for cost savings, a shop’s workflow, technology, and expertise all matter. Here are proven tactics:

- Batch Processing: Grouping similar parts or jobs allows for efficient multi-part fixturing and less frequent tool changes.

- Toolpath Optimization: Using advanced CAM software to minimize tool lifts and travel time reduces overall machine hours.

- Reducing Setups: Designing parts that can be machined in fewer setups, or using 4-axis/5-axis machines, saves time and error risk.

- Process Integration: Combining operations (such as milling and turning on a single machine) avoids multiple handlings and reduces overhead.

- Preventive Maintenance: Well-maintained machines at XTJ CNC ensure reliable operation and high-quality output, lowering the risk of costly rework.

Process optimization is part of XTJ CNC’s core philosophy. Their experienced team assesses every job for efficiency, leveraging technology and best practices to pass savings back to the customer.

Selecting the Right CNC Machining Service

Not all machining shops are equipped, or willing, to work with a cost-conscious mindset. Choosing the right partner makes a difference:

- Proven Experience: Look for a provider with industry expertise, a solid portfolio, and technical understanding. XTJ CNC brings years of hands-on CNC experience serving sectors from medical devices to automotive.

- Transparent Quoting: Reliable quotes and full disclosure on how costs are calculated build trust and support better decision-making.

- Flexibility: A good shop accommodates both prototyping and production, adapts to design updates, and can recommend cost-saving alternatives.

- Local Benefits: Working with a regional provider like XTJ CNC in Carmel means better communication, quick turnarounds, and simple logistics for Indiana-based businesses.

XTJ CNC prioritizes customer collaboration, technical guidance, and budget-friendly solutions rather than simply competing on price. The result is sustainable long-term value, not short-term savings at the expense of quality or service.

About XTJ CNC

Business: XTJ CNC

Spokesperson: Hafiz Pan

Position: Director of Operations

Phone: 8619926417379

Email: [email protected]

Location: 506 S Rangeline Rd, Carmel, IN 46032, USA

Website: cncpartsxtj.com

Frequently Asked Questions About Cost-Effective CNC Machining

What factors influence the cost of CNC machining?

CNC machining costs are influenced by factors like part complexity, material choice, tolerances, batch size, lead time, and labor rates. Understanding these elements can help you make cost-effective decisions during the design and quoting process.

How can I make my CNC project more cost-effective?

To ensure cost-effective CNC machining, simplify part designs, standardize tolerances, choose materials wisely, and design for fewer setups. Collaborating with your CNC provider early can lead to recommendations that lower overall project costs.

What are the best materials for budget-friendly CNC machining?

Cost-effective CNC machining often uses materials like aluminum (such as 6061), acetal (Delrin), nylon, and mild steel. These options offer a balance of machinability, performance, and affordability for a wide range of projects.

How does batch size impact CNC machining costs?

Batch size strongly affects cost per part. Larger orders allow setup and programming costs to be spread across more units, lowering each part’s price. Small batches or prototypes typically have higher unit costs due to upfront requirements.

Can I reduce CNC machining costs by selecting a local provider?

Yes, working with a local CNC machining provider can help reduce shipping costs, shorten turnarounds, and allow for more direct communication. Local sourcing often leads to additional savings and smoother project management.

What is the difference between 3-axis and 5-axis CNC machining in terms of cost?

5-axis CNC machining accommodates more complex geometries in fewer setups, making it ideal for intricate parts. However, it can be more expensive per hour than 3-axis machining due to advanced equipment, though it may reduce overall project costs for complex components.