Woodworking is one of the oldest trades we have. For centuries, people have passed down tools, skills, and techniques to shape wood into homes, furniture, and culture. Even now, the craft still comes down to the human hand. But there’s a new tool stepping into the shop: artificial intelligence. We tend to think of AI as chatbots or data analysis, but its impact is going much further. It’s starting to show up in physical industries, and it’s already clear that it will change how we work with tools, how businesses manage production, and how old trades evolve without losing what makes them timeless.

SAFER WORKSHOPS & LONGER LASTING EQUIPMENT

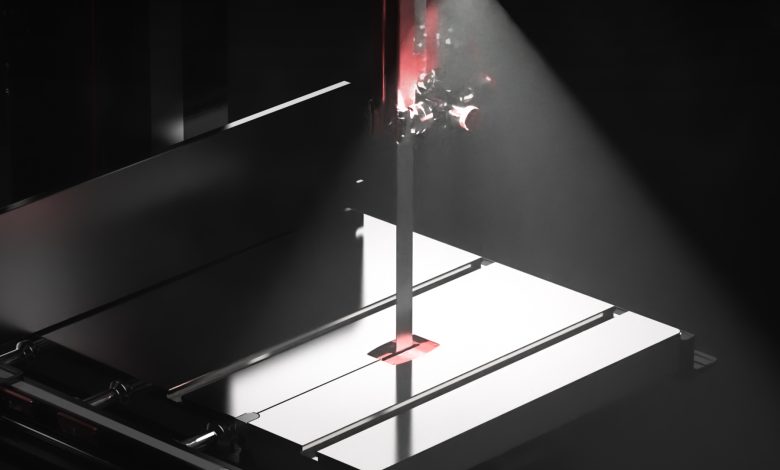

Anyone who has worked around table saws or planers knows how fast things can go wrong. One lapse in focus can lead to injury. This is where AI can be a game-changer. Vision systems can spot danger before the human eye can, creating a new standard for shop safety. Imagine a working with a saw that doesn’t just stop after contact but predicts unsafe movement and cuts power before it happens. For older woodworkers, it adds a peace of mind; for younger ones, it sets a new benchmark for safety from day one.

The same goes for predictive maintenance. AI can sense when a machine is stressed or about to fail. Instead of waiting for breakdowns or accidents, workshops could stay ahead of problems. That means fewer injuries, less downtime, and more confidence for both the worker and the business. With these smart analytics, the system can alert operators before a malfunction occurs, scheduling maintenance during off-hours rather than in the middle of production. For small shops, this kind of foresight protects valuable equipment and keeps projects on schedule. For larger facilities, it means safer, more efficient operations at scale.

QUICKER SET UP FOR EVERY PROJECT

Ask any woodworker what eats up their day, and they’ll tell you: set up. Aligning fences, adjusting blades, calibrating angles, running test cuts; the process can take longer than the actual build. AI has the potential to shrink that wasted time. By analyzing the material, understanding the cut, and automatically fine-tuning the machine, AI can take the guesswork out of setup. It gets you from planning to working faster.

CNC machines already automate complex cuts, but with AI, they can do more: optimize cut paths, check for errors in real time, and even recommend design tweaks. Less trial and error, more accuracy, and a smoother workflow for everyone in the shop. Beyond just saving minutes or hours, this kind of automation can help ensure precision from the very first pass. AI-driven systems could remember preferred settings for specific woods or projects, adjusting instantly when you switch from oak to maple or from ripping to dado cuts. Cameras and sensors could verify alignment down to fractions of a millimeter, guaranteeing repeatability that even experienced hands struggle to achieve manually.

CUT DOWN ON WASTE IN THE WORKSHOP

Wood is expensive and wasting it hurts financially and environmentally. AI can help by laying out cut patterns that use every inch efficiently. At scale, it can forecast demand and line up supply chains so businesses only use what they need. That’s not just about saving money. It’s about building a trade that’s more sustainable for the long term. The woodworker’s touch stays the same, but the process around it becomes smarter.

SUPPORTING CREATIVITY NOT REPLACING IT

The fear with AI is always: will it replace me? In woodworking, the answer is no. AI won’t replace the craftsman’s creativity or skill. What it will do is take on the repetitive, risky, or time-consuming parts of the job. Think about when calculators showed up—they didn’t eliminate mathematicians, they just freed them to focus on bigger problems. AI is the same.

It’s a partner, not a competitor.

In fact, AI can help preserve craftsmanship rather than erase it. By handling tedious setup, monitoring safety, or tracking material performance, it allows woodworkers to devote more attention to the artistry; the part that can’t be automated. The grain selection, the hand-finish, the subtle design decisions that make each piece unique still depends on human touch and judgment. What changes is that the tools get smarter, the workspace gets safer, and the maker has more mental space to think creatively.

The workshop of the future isn’t going to look like a factory run by robots. It will still smell like sawdust. It will still be filled with the sound of machines and people shaping wood. The difference is that AI will be there too—quietly making the work safer, faster, and more efficient.

AI isn’t an outsider in this trade. It’s the next evolution of the tools we’ve always used. From the first hand-plane to today’s smart machines, every new step has been about one thing: helping people build better. AI is just the latest, and maybe the most powerful, tool in that long line.