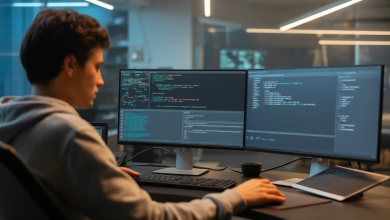

I’ve seen firsthand how artificial intelligence has been rapidly changing the manufacturing industry, touching everything from supply chain predictive analytics to design for manufacturability analysis to workflow automation. And with the explosion of ChatGPT and large language model technologies, there’s a newly invigorated energy around the potential of AI to solve some of manufacturing’s biggest challenges: Supply chain speed, visibility, and operational efficiency.

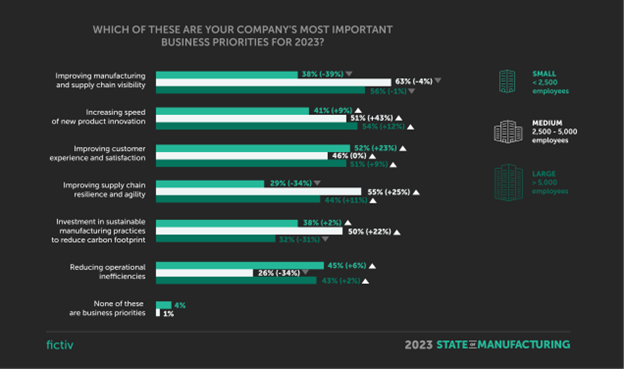

Research backs this up. In the 2023 State of Manufacturing Report, 97% of manufacturing leaders expect AI to impact product development, and 85% have already adopted or plan to adopt AI solutions.

Keep reading for what I believe are some key ways manufacturing leaders can leverage AI today to automate workflows, improve customer experience, and increase supply chain visibility.

Optimizing Workflows

If you’re like most manufacturing and supply chain leaders, you’re laser-focused on ways to improve margin, lower costs, and improve supply chain operational efficiency. AI has enormous potential to help here.

Because of the fragmented nature of many global supply chains, there is a ton of manual work involved in managing procurement via hundreds or even thousands of tier 2 and tier 3 suppliers. Activities like sourcing new suppliers, onboarding suppliers, requesting quotes, reviewing design for manufacturability feedback, requesting order status updates, troubleshooting order issues, and triaging disruptive supply chain events — all of these tasks combined add up to a significant amount of friction and drag in the sourcing and manufacturing process that has a real impact on the bottom line.

That’s where AI comes in. AI technology today can automate many of these manual tasks to dramatically accelerate and streamline the procurement process. For example, AI algorithms can instantly price a part for manufacturing, saving days or weeks on quoting today. Similarly, AI can analyze the manufacturability of a part, streamlining the communication between a supplier and an engineer. AI-powered predictive analytics can also help with demand forecasting, inventory management, and supplier risk management.

AI should not replace the people involved in many of these processes, but it can improve human productivity in manufacturing significantly and drive lean operations at a time when manufacturing companies need to improve profitability.

Improving Customer Experience

Many manufacturers already use AI for everything from quality control and inspections to 3D printing, but leveraging AI to improve customer experience is also promising. Rich language modeling continues to evolve by enabling more contextual questions, redirecting common customer questions to automated systems, and communicating product developments and improvements as they happen. This means customers who expect speed, efficiency, and relevance can get their issues addressed quickly or escalated to the right team. As an AI-assisted option, it’s no replacement for human interaction but is a supplement to foster better customer relationships.

For many companies, digital manufacturing leveraging AI accelerates design, material selection, quality feedback, and shipping processes. Additionally, customer expectations keep rising, and demand for relevant, personalized experiences has reached critical mass. Leveraging AI to deliver the right information at the right time is more critical than ever.

Increasing Supply Chain Visibility

Increasing supply chain visibility is top of mind for manufacturing leaders (56% of large manufacturers identify improving supply chain visibility as a top business priority). By aggregating data and generating insights over time, AI can connect disruptions ranging from geopolitical instability to weather patterns and economic volatility to predict risk and surface solutions that help mitigate those risks.

AI-driven systems provide end-to-end visibility into the supply chain by integrating and analyzing data from multiple sources. This transparency allows companies to identify bottlenecks, inefficiencies, and potential risks across the supply chain. With a clear understanding of the entire ecosystem, organizations can make informed decisions that enhance overall resilience.

AI tames large volumes of data and turns it into insights. It can help you save energy, reduce waste, and improve efficiency. It’s like having a manufacturing guru offering insights that lead to better resource utilization. AI can quickly catch product flaws and manufacturability issues, and flag errors before they lead to a total project breakdown.

What’s Next for AI in Manufacturing?

AI transforms manufacturing by introducing intelligence and automation into various processes. The result is a more agile, efficient, and innovative manufacturing ecosystem that can adapt to the dynamic challenges of the industry. I anticipate that eventually, we’ll be able to input our requirements conversationally and even upload other assembly components and allow AI to provide not only geometrical suggestions but also material suggestions based on application or use case. It will be exciting to see where AI will take manufacturing in 2024.