3D printing is an additive manufacturing technique commonly used in various manufacturing processes. Its additive features make that not needed—a material block or mold for making different objects. In this process, just material layers are stacked and connected. It is a high-speed process, has low-cost equipment, and makes complicated designs compared to other techniques. In this post, we will cover details of the features of 3D printing and related factors.

What is 3D printing?

- 3D printing, another name for the additive manufacturing process, is used for making 3D objects with CAD models. This process is performed with different methods where metal deposition, connection, and solidification with computer control and materials are connected in layers.

- In the 1980s, the 3D printing process was used for making functional prototypes and was best for the rapid prototyping process.

- In 2019, precision, accuracy, and materials used for 3D printing make the 3D printing process useful for industrial-based manufacturing processes.

- The main feature of 3D printing is to make complicated designs that are difficult to make manually, like hollow parts, and it reduces weight and uses fewer materials.

- Fused deposition modeling uses a continuous filament process for thermoplastic material and is a common 3D printing process.

Best 3d printing service

JUSTWAY 3D service provider is one of the famous 3D service providers in the world; they cover on-demand 3D manufacturing and other services rapid prototyping to mass production. They come with an advanced online quoting system and transform designs into high-quality prototypes and parts that meet our requirements.

. Justway has many years of experience in the precision manufacturing process, and their main objective is to be your professional and reliable custom manufacturing service expert.

Some features of their online 3D printing service are

- Instant Quotes & DFM Feedback

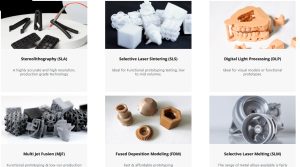

- SLA, MJF, DLP, FDM, SLM, SLS, PolyJet, SAF Technologies

- Manufacturing Low-Volume Parts

With over 250 sets of industrial-grade 3D printing equipment, print parts in 1 day.

Their 3D printing service includes

| SLA | SLS | MJF | FDM | SLM | |

| Lead time in days | From 1 days | From 2 days | From 2 days | From 2 days | From 2 days |

| Available materials | Resin / Somos | PA12 / PA12GB | HP-PA12 | PLA / ABS | Aluminum (AlSi10Mg) |

| Tolerances | +/- 0.2 mm | +/- 0.25 mm | +/- 0.25 mm | +/- 0.2 mm | +/- 0.3 mm |

| Max Part Size | 2100 x 800 x 700 mm | 400 x 390 x 390 mm | 380 x 380 x 284 mm | 1300 x 1300 x 1300 mm | 300 x 300 x 300 mm |

| Applications | Detailed visual prototypes (especially of injection molded parts). | Functional and high-fidelity prototypes. | Functional and high-fidelity prototypes. | Low-fidelity, proof-of-concept prototyping and visual design verification. | Functional and metal prototypes. |

How Does 3D Printing Work?

The 3D printing process involved different techniques, commonly used fused deposition modeling, called fused filament fabrication.

- In this process, a filament made of acrylonitrile butadiene styrene, polylactic acid, or a thermoplastic is melted and deposited in layers using a heated extrusion nozzle.

- Before starting the printing process, a 3D model of the object is made. The computer model was cut and divided into different layers. that details are given to the 3D printer, and it prints the object in slice form

- • The main feature of this process is that the complicated design is made into an easy process with the application of fewer materials than other manufacturing processes.

- It reduces extra cost for transportation since all components are made at the same locations.

- It also helps to make products quickly without extra expenses.

3D Modeling Software

- 3D printing started with 3D modeling. For high accuracy, all particles are designed in 3D modeling software.

- Some designs take time and are more complicated and effective than older methods.

- So CAD software is used for modeling in 3D designing, which helps printers to make products in detail.

- 3d printing software has features to give accurate details for design and for indusries manufacutring.

- This modeling software is part of different industries where 3D printing of different objects can be done easily. It is also important for the space industry to make complex designs of different aircraft.

3D Printing Materials

Different materials used for 3D printing areas

Acrylonitrile butadiene styrene (ABS)

- Plastic materials can be easily converted into different designs without breakage.

Carbon Fiber

- Carbon fiber is used for making objects that are strong in design and low in weight.

Conductive Filaments:

- This material is used for making circuits without using wires. It is preferred for wearable technology.

Flexible Filaments:

- Flexible filaments make bendable prints that are strong in design. This material made wristwatches and phone covers

Metal Filament:

- They are good ground materials and polymer stick materials. They are steel, bronze, and copper for creating the design of metallic objects.

Wood Filament:

- These filament ground powders are mixed with polymer glue. It is used for wooden designs and is lightweight according to the temperature of the printer.

3D Printing Techniques

different methods used for making 3D printing designs and processes that are

Fused Deposition Modeling (FDM)

- FDM is a commonly used 3D 3dprinting type.that for making prototypes and plastic models.

Stereolithography (SLA) Technology

- SLA high-speed prototyping printing that is good for complex design. The printer will work with a UV laser for making objects shortly.

Digital Light Processing (DLP)

- DLP: an older type of 3D printing process. DLP works with light sources for making prints with high speed compared to SLA processes since it dries layers quickly.

Continuous Liquid Interface Production (CLIP)

- clip high-speed process that works with vat photopolymerization. The CLIP process uses digital light synthesis methods for making objects in UV images over the cross-section of 3D design parts, causing a controlled curing process. This component is baked in a thermal bath, resulting in different chemical reactions that make the part harden.

Selective Laser Sintering (SLS)

- Powder bed fusion type, SLS fuses particles of powder through a high-power laser for making 3D designs. Laser scans layers on the powder bed and fuses; after that, lower the powder bed by a single layer and start the process until completed.

Multi-Jet Fusion (MJF)

- Mjf employs sweeping arms for depositing power and an injection arm, for applications binder on the upper part, after that agent is applied over a detailed agent for accuracy. Thermal energy is used for chemical reactions. Direct metal laser sintering is used with a process for metal powder specifically.