AI-driven forecasting is redefining supply-chain resilience, improving telecom readiness and national infrastructure stability.

Three days before a Category-4 hurricane made landfall along the Gulf Coast, a predictive AI model quietly triggered a surge order across regional warehouses. When the storm passed, thousands of displaced residents lined up to replace damaged phones and SIM cards — and found shelves stocked. What once required weeks of reactive recovery now unfolded in real time.

This was no coincidence. It was the result of a machine-learning–driven forecasting system built to safeguard America’s communications backbone — a lifeline designated by the Department of Homeland Security as critical infrastructure. By turning data into foresight, the platform ensured continuity of connectivity when it mattered most, embodying a new principle of national resilience: anticipate, don’t react. The lessons from this initiative extend far beyond one network. They form a national blueprint for AI-enabled, disaster-ready supply chains that directly strengthen U.S. economic and security interests.

The Problem: Systemic Fragility in Critical Supply Chains

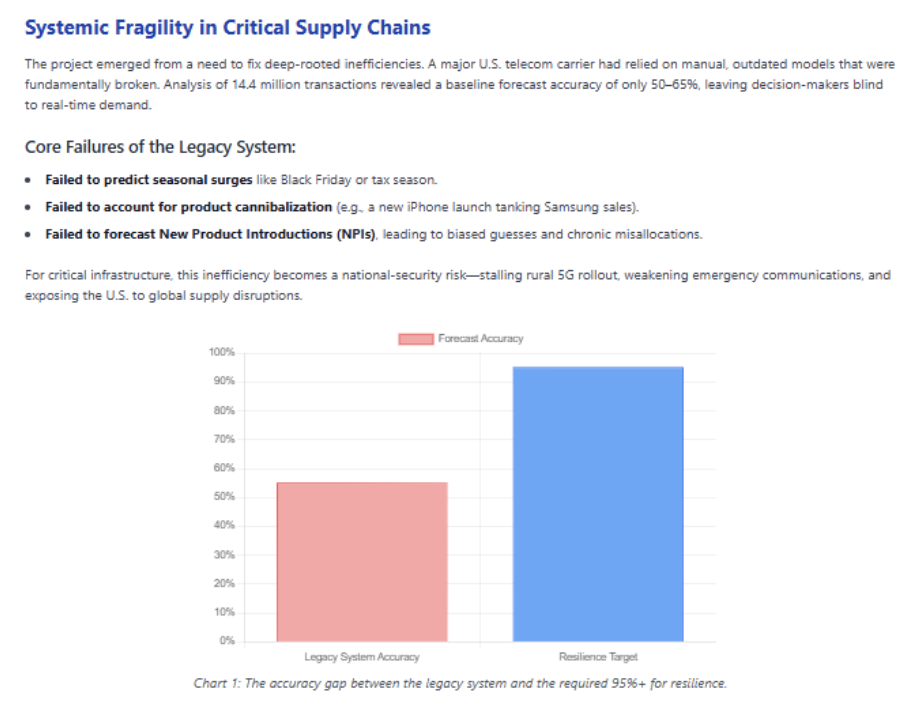

Figure 1. Forecast Accuracy Gap: The accuracy gap between the legacy system (~60%) and the required 95%+ for resilience.

The hurricane response exposed deep-rooted inefficiencies. A major U.S. telecom carrier’s legacy forecasting models were broken—analysis of 14.4 million transactions showed only 50–65 % accuracy (Figure 1). The system failed to predict seasonal surges like Black Friday or account for product cannibalization, causing empty shelves or costly overstock. Forecasts for New Product Introductions (NPIs) were biased guesses, perpetuating waste. For critical infrastructure, such inefficiency poses a national-security risk—stalling rural 5G rollout, weakening emergency communications, and exposing the U.S. to global supply disruptions.

From Data Chaos to Decision Intelligence

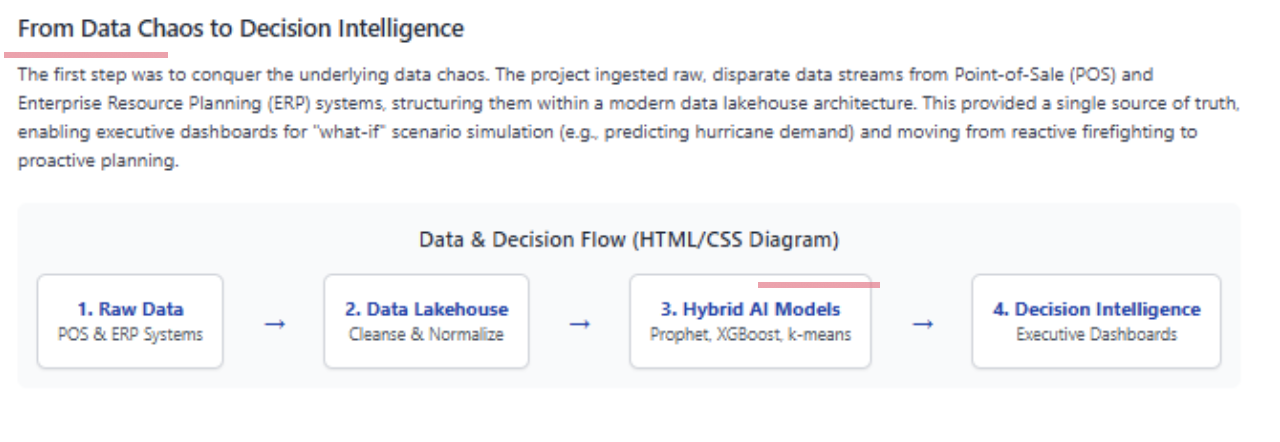

The first step in building a resilient system was to conquer the underlying data chaos. The project ingested raw, disparate data streams from Point-of-Sale (POS) systems and Enterprise Resource Planning (ERP) databases across a vast retail network. This data was cleansed, normalized, and structured within a modern data lakehouse architecture.

This architecture provided a single source of truth, transforming fragmented data into a coherent asset. Robust data anonymization protocols and strict access controls were implemented to ensure compliance with consumer privacy standards and FCC data-handling guidelines, building security into the foundation of the platform.

The ultimate goal was not just forecasting, but decision intelligence. Executive dashboards were developed to translate complex model outputs into actionable insights. These dashboards enabled the kind of scenario simulation that made the hurricane response possible. Planners could run “what-if” analyses for natural disasters, major promotions, or supplier disruptions. The AI could predict a 40% demand surge for replacement devices in specific regions, enabling the proactive pre-positioning of inventory days before a crisis. This capability to move from reactive firefighting to proactive, scenario-based planning marked a fundamental shift in the supply chain’s operational philosophy, embedding resilience directly into the decision-making process.

The AI Forecasting Blueprint: A Hybrid Machine Learning Architecture

A hybrid machine learning architecture replaced “gut-feel” forecasting with scalable, automated intelligence (Figure 2).

Figure 2. AI Forecasting Blueprint: End-to-end data-and-decision flow illustrating data ingestion, lakehouse processing, hybrid ML models, and executive dashboards that transform fragmented inputs into intelligent, resilient planning.

- Time-Series Engine (Prophet) We used Meta’s Prophet, trained via Apache Spark, for its superior handling of strong seasonality and changepoints. This allowed for generating highly granular forecasts for hundreds of thousands of individual store-SKU combinations, a scale impossible with manual methods.

- Non-Linear Modeling (XGBoost) An XGBoost regression model was deployed—chosen over deep learning models like LSTMs for its performance and interpretability on tabular data. It accurately quantified the complex, non-linear impacts of promotions and product cannibalization.

- New Product Forecasting (K-Means) A k-means clustering algorithm addressed the “cold start” problem for NPIs. It grouped new products with historical “look-alike” products based on a multi-dimensional feature vector (price, brand, specs), eliminating human bias and providing a statistically grounded baseline.

Automated Python pipelines ensured the models continuously learned from new data, creating a living supply chain nervous system.

Quantified Impact: Resilience Measured in Key Performance Indicators

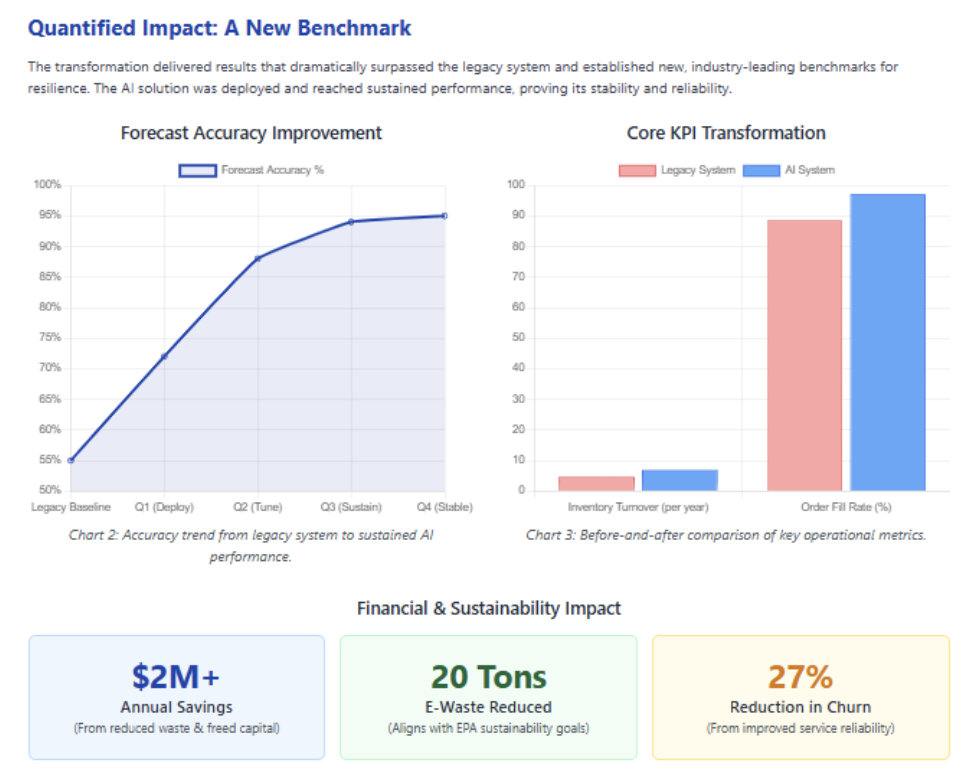

The transformation delivered results that dramatically surpassed the legacy system’s performance and established new, industry-leading benchmarks for resilience.

- Forecast Accuracy: Accuracy improved from a baseline of 55-60% to a sustained 95%, equivalent to a ~5% Weighted Mean Absolute Percentage Error (WMAPE). This level of precision far exceeds the Institute of Business Forecasting’s industry baseline of ~30% SKU-level error for one-month-ahead forecasts, providing an unprecedented crystal ball into future demand.

- Service Levels and Disaster Readiness: The order fill rate increased to 97.1%, decisively exceeding the Institute for Supply Management’s high-performer threshold of >95%. This metric is not merely an operational KPI; it is a direct contributor to public safety. A high fill rate for essential components like SIM cards and devices ensures that a carrier can rapidly meet the sudden, high-volume demand spikes that follow natural disasters, directly supporting compliance with the FCC’s Mandatory Disaster Response Initiative (MDRI).

- Inventory Efficiency and Sustainability: Inventory turnover—a key measure of how efficiently capital is deployed—accelerated by 51%, from 4.5x to 6.8x annually. This moves telecom device logistics closer to the 8-11x norms reported for leading U.S. retail and consumer electronics firms. By reducing overstock, the project also prevented an estimated 20 tons of electronic waste annually, aligning with the Environmental Protection Agency’s (EPA) Sustainable Materials Management goals.

- Operational and Financial Resilience: Stockouts were reduced by nearly 30%, a significant improvement over the persistent 8% national retail average. Service reliability improved, reducing churn by 27% and retaining revenue. Overall, the project generated over $2 million in annual savings by reducing waste and freeing up tied-up capital—resources that can be redirected toward strategic national priorities like network expansion and security hardening.

Figure 3. Forecast accuracy and sustainability gains — 95% accuracy, 97.1% fill rate, $2M savings, 20 tons e-waste cut.

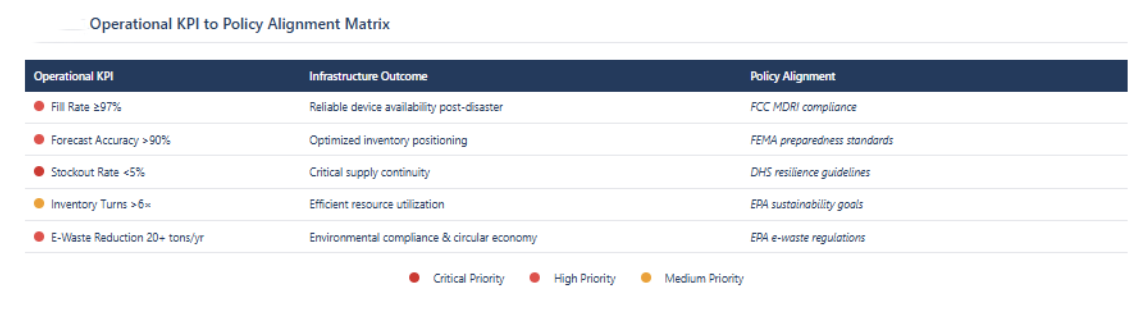

National Policy Alignment: Strengthening Federal Initiatives

The impact of this project resonates powerfully with a wide array of current U.S. federal policies and investment priorities, demonstrating how technological innovation in the private sector can amplify public goals.

- FCC 5G Fund and BEAD Program: The significant operational savings directly enable capital to be reallocated to network infrastructure projects. This supports the explicit mission of the FCC’s 5G Fund for Rural America and can accelerate buildouts under the monumental Broadband Equity, Access, and Deployment (BEAD) Program, ensuring no community is left behind in the digital divide.

- CHIPS and Science Act: By creating a more predictable and efficient demand signal for semiconductor-dependent devices, this supply chain model supports the objectives of the CHIPS and Science Act to bolster the domestic semiconductor ecosystem and reduce reliance on fragile global supply chains.

- Cybersecurity and Secure Software: The project’s focus on robust data governance and secure system architecture aligns with DHS’s initiatives for Information and Communications Technology (ICT) Supply Chain Risk Management (SCRM) and evolving guidelines from the NTIA on 5G Cybersecurity. A resilient supply chain is a secure supply chain.

Figure 3. Operational KPI to Policy Alignment Matrix: Maps telecom performance metrics to FCC, FEMA, DHS, and EPA frameworks.

A Model for Other Critical Sectors

The architecture and methodologies developed for telecommunications are highly generalizable, providing a scalable framework for enhancing resilience across other foundational U.S. sectors.

- Semiconductors: The same hybrid forecasting approach can predict demand for new chips and account for complex market factors, strengthening the entire domestic semiconductor supply chain from design to fabrication.

- Defense: The model’s proven ability to handle intermittent and “lumpy” demand patterns is directly applicable to managing complex spare parts logistics for military platforms, ensuring readiness without bloated inventory.

- Healthcare: This blueprint can be adapted to optimize the supply chain for critical medical equipment, pharmaceuticals, and vaccines, ensuring that life-saving supplies are available and equitably distributed during public health crises.

This replicability demonstrates that the project’s impact is a template for national modernization, offering a proven path to secure the material foundations of American security and prosperity.

Future Vision: Integrating Blockchain Traceability and AI Optimization

The AI forecasting platform is a foundation for an end-to-end, autonomous supply chain. The logical progression is to extend this platform with blockchain-based traceability. While the AI model predicts demand, a permissioned blockchain can provide an immutable, auditable record of a device’s journey from manufacturer to end-user. This would create tamper-proof provenance, effectively guarding against counterfeit part infiltration—a critical threat to network security—and providing unparalleled visibility into supplier lead times.

Figure 5. Future Vision Architecture: Integration of AI forecasting, blockchain traceability, and AI optimization to build an autonomous, secure, and resilient supply chain.

Furthermore, the current forecasting model can be evolved into a multi-echelon inventory optimization system. This AI would not only predict demand but also automatically prescribe the optimal allocation of scarce components and finished goods across the entire network—from central warehouses to regional distribution centers and individual retail stores. This would minimize total system-wide cost and maximize service levels even during severe disruptions.

Integrating these capabilities—AI forecasting, blockchain transparency, and autonomous optimization—would harden critical infrastructure supply chains as a definitive line of defense against global disruptions, fraud, and cyber threats, directly supporting NTIA’s vision for a secure software supply chain and national economic security.

Why It Matters for America’s Resilience

AI-driven forecasting is not just an efficiency tool—it is a safeguard for national stability. By anticipating supply-chain shocks, it protects communications lifelines during natural disasters, supports the equitable rollout of 5G and broadband, and reduces environmental waste. Embedding intelligence into logistics ensures that public safety, sustainability, and economic competitiveness advance together, creating a stronger, more connected United States.

Conclusion

This AI-driven supply chain transformation demonstrates conclusively that data science is not merely a tool for corporate efficiency but a foundational technology for national resilience. By delivering unprecedented forecasting accuracy, operational efficiency, and disaster readiness—as proven in the face of a Category-4 hurricane—the project directly strengthens the U.S. telecommunications sector, a vital component of our critical infrastructure.

The quantified results—95% forecast accuracy, a 97.1% fill rate, and $2 million in annual savings—provide tangible proof of concept. More importantly, the project’s alignment with key federal initiatives like the CHIPS Act, FCC 5G Fund, and EPA sustainability goals shows how private-sector innovation can accelerate national priorities. Embedding intelligent forecasting into America’s critical infrastructure planning ensures that resilience becomes a designed-in principle, not an afterthought. This blueprint offers a scalable, replicable model to secure the supply chains that power our nation, ensuring America remains secure, competitive, and prepared for the challenges of the future.

About the Author

Lakshmanaprakash Murugesan is a U.S.–based supply-chain and data-analytics professional with experience at Boost Mobile, Amazon Fresh, Amazon Prime Air, and ROHA USA. Over the past decade he has led AI-driven forecasting and multi-echelon inventory-optimization initiatives that improved resilience, efficiency, and sustainability across telecommunications and retail networks. Beyond his industry work, he contributes to thought-leadership on national infrastructure modernization, aligning advanced analytics with U.S. broadband, 5G, and supply-chain-security priorities.

Disclaimer: All data and examples are anonymized and illustrative; no proprietary or confidential information is disclosed.