In the world of industrial automation, we’ve spent decades perfecting the hardware. We built bigger resonators, more rigid frames, and faster linear motors. But in 2026, the real revolution isn’t just in the power of the beam—it’s in the “brain” behind it. As a veteran in the fabrication industry, I’ve seen the shift from manual “dial-in” settings to the current era where fiber laser cutting systems are becoming self-aware, data-driven entities.

If you are still looking at your fiber laser cutter as just a high-powered torch, you are missing the forest for the trees. We are now entering the age of “Cognitive Fabrication,” where AI and laser beam machining converge to eliminate waste, predict failure, and achieve a level of laser cutting precision that was once thought impossible.

The End of “Guesswork”: AI Meets Laser Beam Machining

In the old days, a skilled operator spent half their shift adjusting gas pressure, focal positions, and feed rates based on the “sound” of the cut. It was an art, not a science. Today, that “art” has been digitized.

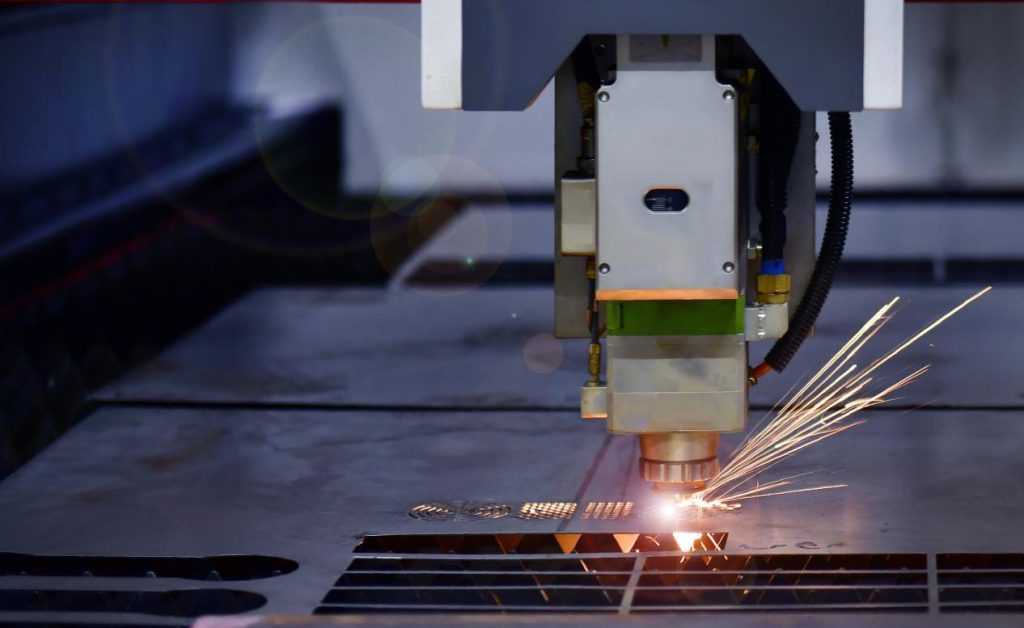

Modern laser beam machining now incorporates real-time sensor fusion. We’re talking about high-speed cameras and acoustic sensors that “watch” and “listen” to the plasma plume. When the system detects a micro-burr forming or a slight deviation in the kerf, the AI adjusts the parameters in milliseconds—faster than any human could blink. This isn’t just about speed; it’s about a fiber laser cutting machine that learns the nuances of different material batches, compensating for imperfections in the steel before the first spark even flies.

Maximizing ROI Through Intelligent Nesting and Edge Computing

For any business owner, the biggest “drain” on the bottom line is material waste. In a traditional shop, scrap rates of 15-20% were often accepted as the cost of doing business.

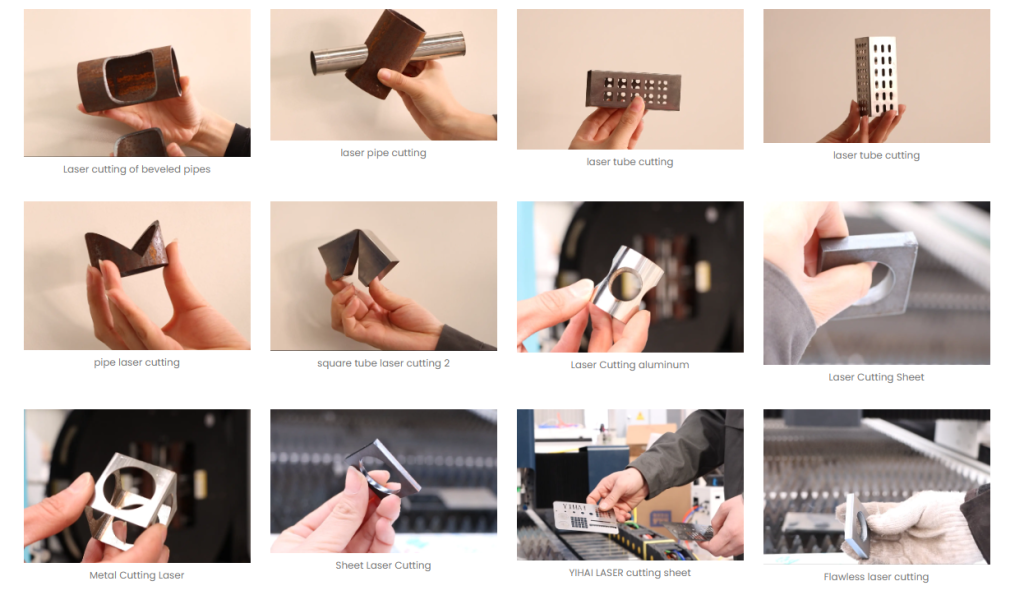

By integrating advanced algorithms into the fiber laser cutting system, we are seeing a “Nesting Revolution.” Modern software doesn’t just fit shapes onto a sheet; it calculates thermal paths to prevent heat-warping and uses “common-line cutting” to save every possible millimeter of material. When you combine this with the sheer velocity of a 20kW or 30kW steel plate laser cutting machine, the ROI shifts from years to months. You aren’t just cutting metal; you are optimizing your entire cash flow.

The Structural Backbone: Why the Laser Cutting Machine Bed Matters

On a tech-heavy site like AI Journal, we often obsess over the software. But in the world of high-speed photonics, hardware is the “physical layer” that enables the code.

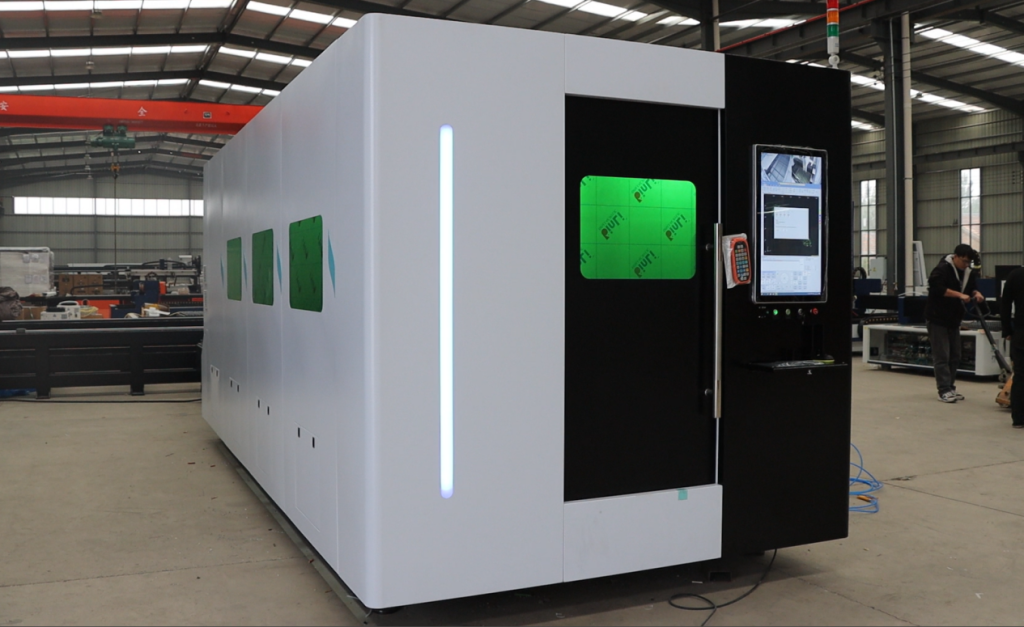

If your laser cutting machine bed isn’t engineered to dampen the extreme vibrations of high-G acceleration, all the AI in the world won’t save your edge quality. We’re seeing a shift toward hybrid mineral-casting beds and reinforced hollow structures that provide the thermal stability needed for 24/7 industrial automation. A stable bed is what allows the laser to maintain its micron-level focus while moving at speeds that would make a race car jealous.

The Rise of the “Dark Factory”: Automation and Connectivity

The ultimate goal for any forward-thinking manufacturer is the “Dark Factory”—a facility that runs with the lights off, fully autonomous.

We are closer than ever. By connecting a tube laser for sale or a flat-bed system to a centralized ERP via IoT, the machines can now manage their own maintenance schedules. Predictive maintenance algorithms analyze the “health” of the laser source and the optics, ordering replacement parts before a breakdown occurs. This level of industrial automation ensures that the machine is always at peak performance, turning “downtime” into a relic of the past.

Sustainability: The Green Side of High-Power Lasers

There’s a misconception that high-power lasers are energy hogs. In reality, the move to fiber laser cutting machine technology has been a massive win for sustainability.

Fiber lasers have a wall-plug efficiency that is 3 to 4 times higher than old CO2 systems. When you add AI-optimized cutting paths that reduce “dry run” time and material waste, the carbon footprint of each part drops significantly. For companies looking to meet 2026 ESG standards, upgrading to an intelligent fiber laser cutter is one of the most effective ways to “green” the supply chain without sacrificing productivity.

Conclusion: Betting on Light and Logic

The fabrication floor of the future isn’t about brute force; it’s about the synergy between light and logic. Whether you are cutting intricate patterns for laser cut fabric or heavy-duty components with a steel plate laser cutting machine, the winners will be those who embrace the “Smart Factory” mindset.

Choosing a system from a brand like YIHAI LASER isn’t just about buying a tool—it’s about investing in a platform that evolves. As we continue to push the boundaries of what industrial automation can achieve, the laser will remain the ultimate instrument of precision, turning digital designs into physical reality at the speed of light.