SHANGHAI, Oct. 16, 2025 /PRNewswire/ — Today, Agibot officially launched its next-generation industrial-grade interactive embodied robot, Agibot G2. Built to industrial standards, this robot integrates high-performance motion joints, high-precision torque sensors, and an advanced spatial perception system. It combines rapid learning and deployment capabilities with multimodal voice interaction functions, and is adaptable to multiple scenarios including industrial production, logistics, and guided tours – poised to reshape the application landscape of industrial-grade embodied robots.

“We envision Agibot G2 relieving humans from repetitive, labor-intensive, and safety-risk prone work, enabling people to focus on more creative tasks,” stated Dr. Yao Maoqing, Partner at Agibot, Senior Vice President, and President of the Embodied Business Unit.

Enhanced Hardware for Excellent Operation

As an upgraded version of the model released in November 2023, Agibot G2 has emerged as a global benchmark for industrial-grade embodied operations, driven by three core hardware strengths. Equipped with high-performance joint actuators and multi-type sensors, it enables full-scene omnidirectional obstacle avoidance.

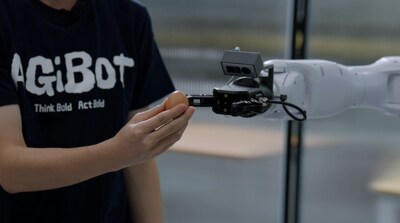

Its 3-degree-of-freedom waist design accurately simulates human movements such as bending, twisting, and side swaying. Complementing this is the world’s first cross-shaped wrist force-controlled arm – equipped with high-precision torque sensors across the entire arm, it can detect external forces in real time and achieve smooth responses via impedance control.

Additionally, a dedicated rapid deployment toolchain allows non-professional users to complete setup without specialized skills, while the dual-battery hot-swappable design and autonomous charging function support 24/7 continuous operation, perfectly matching the rhythm of factory production lines.

Interactive AI Innovation for Smarter Operations

Agibot G2 breaks the limitations of traditional industrial robots — which only perform one-way operations — and creates a more intelligent operational experience, powered by the dual drivers of “interaction + AI”.

Powered by Agibot’s in-house developed foundational large model GO-1 and world model GE-1, the G2 sees a comprehensive upgrade in handling complex and long-sequence tasks. GO-1 features a “3-layer brain” architecture — starting with VLM for perception, followed by Latent Planner for planning, and Action Expert for execution — enabling the robot to “understand a single command and complete an entire task.” GE-1 brings predictive capabilities for future scenarios in time and space, allowing it to “rehearse” actions in a visual environment to tackle extended, intricate operations.

Thanks to the NVIDIA Jetson Thor T5000’s impressive on-board computing power of up to 2070 TFLOPS (FP4), the G2 delivers real-time responses and decisions, processing multiple sensor streams locally with latency under 10 ms. This setup allows larger-scale AI models like VLAs and LLMs to run directly on the device, boosting performance and generalization while slashing development timelines — models can be trained and tested in virtual simulations before seamless one-click deployment to physical robots, cutting trial-and-error costs and time.

Interactive AI Innovation for Smarter Operations

The Agibot G2 emphasizes industrial-grade quality for reliable performance in commercial applications, passing over 130 component tests and extreme trials like temperatures from -15°C to 50°C, electrostatic protection, and emergency braking. This ensures safe, low-maintenance automation that cuts costs and boosts efficiency for businesses.

The press conference featured four live demos of real-world deployments: in auto parts production, it collaborates with humans on seatbelt lock cylinder assembly and material handling; for precision tasks, its force-controlled arms and AI learning enable quick mastery of delicate operations like RAM insertion in one hour; in logistics, the OmniHand grips diverse parcels, with autonomous navigation suiting 95% of factory floors; and for guided tours, it uses human-like body language and 360-degree sensors for engaging, safe interactions.

For logistics sorting, it has been applied to the parcel feeding and loading process – supported by Agibot’s high-degree-of-freedom tactile dexterous hand OmniHand (professional version), G2 can effectively grasp parcels of various sizes, shapes, and materials. Before the completion of the current batch of loading tasks, another Agibot G2 can quickly transport subsequent materials to the buffer area via autonomous navigation; its strong mobility and good passability enable it to adapt to over 95% of factory floor conditions.

In commercial guided tour scenarios, Agibot G2 demonstrates strong interactive capabilities: based on a customized knowledge base and full-body high-degree-of-freedom design, it features more human-like body language, making explanations more vivid and natural. Sensors around the robot enable omnidirectional perception and hazard prediction, fully ensuring user safety.

The Agibot G2 offers SDK interfaces for industry-specific customizations, and Agibot is expanding into security, inspections, education, and research to widen its applications.

Deployment in Key Sectors

Following successful scenario-based demos, Agibot G2 has begun formal deployment in key industrial sectors. Today, the Agibot G2 is officially rolling out in automotive parts manufacturing applications. Previously, it has already made inroads into core areas of consumer electronics precision manufacturing.

About Agibot

AgiBot is dedicated to driving innovation through the integration of AI and robotics, creating world-leading general-purpose embodied robot products and an application ecosystem. Built on the foundation of robot ontology and powered by the fusion of interaction, manipulation, and locomotion intelligence – “1 Ontology + 3 Intelligence”, AgiBot is the only robotics company in the industry to deliver a complete product portfolio and deploy across all major application scenarios.

View original content to download multimedia:https://www.prnewswire.com/news-releases/agibot-unveils-next-gen-industrial-grade-interactive-embodied-robot-agibot-g2-302586152.html

SOURCE Agibot