Introduction

Turning stainless steel threads is one of the most challenging operations in CNC machining services. Along with unpredictable tool wear and work hardening of the material, minute variations will result in out-of-spec threads that force many machinists to put up with high levels of scrapped parts, costly rework, and delayed projects. The root of the problem is that conventional techniques lack real-time data and adaptive intelligence to manage such complex dynamics proactively.

Following are five AI-informed strategies currently changing this key process. Using smart technologies, manufacturers will be able to go beyond the mere reactive problem-solving approach to predictive optimization, achieving levels of precision, efficiency, and cost-effective production in stainless steel thread production never seen before.

How does AI-powered manufacturing optimize parameters in Stainless Steel Thread Turning?

Precise thread turning is all about the right interrelationship among three parameters: cutting speed, feed rate, and depth of cut. But these are not fixed parameters since they have to adjust to material lot variations, tool condition, and even ambient temperature.

1. The Challenge of Static Parameters in a Dynamic Environment

Applying only one set of “optimal” parameters copied from a handbook is usually not enough. The immediate work-hardening tendency of stainless steel means that as a tool wears, the cutting forces and temperatures rise, which accelerate the wear, further deteriorating the thread surface finish in a negative feedback.

2. AI as the Adaptive Brain

AI and machine learning algorithms can analyze real-time sensor data, such as vibration, acoustic emissions, power consumption, to identify subtle patterns that are indicative of optimal or suboptimal cutting conditions. This, in turn, enables the system to dynamically readjust the parameters on the fly and maintain a stable and efficient cutting process throughout the tool’s life.

3. Ensuring Consistency Through Systematized Expertise

Of course, such a system requires a robust framework so it works reliably. For example, a contract manufacturing partner with an ISO 9001: 2015-certified quality management system will provide the structured data needed to train and validate the artificial intelligence models so that adaptive intelligence produces repeatable, high-quality results batch after batch.

What Role Does Predictive Maintenance Play in Extending Tool Life for Thread Turning Operations?

Figure 2: Predictive maintenance system workflow comparing traditional vs AI-optimized tool replacement strategies

Tool failure during a thread turning operation doesn’t just ruin a part, it can damage the workpiece and the machine spindle. Traditional time-based tool changes are either wasteful – replacing a tool with remaining life – or risky, a tool failing prematurely.

- The High Cost of Unplanned Tool Failure: A broken tap or insert in the middle of a deep, blind hole can lead to hours of costly rework or even a scrapped component, blowing out production costs and timelines.

- From Scheduled to Predictive Replacement: Predictive maintenance relies on sensors that directly monitor tool health. Through analysis of the trend in cutting force or vibration, for example, the AI can predict with a high degree of accuracy how much longer a particular tool has before the end of its optimal life and notify the machinist when it is time to replace it. This maximizes the tool utilization and avoids unplanned downtime.

- A Partner with a Foresight Capability: A manufacturer with a mature predictive maintenance program underpinned by such standards asIATF 16949 brings a level of foresight to production planning.This capability ensures that tooling is managed as a strategic asset, directly contributing to on-time delivery and cost predictability.

| Comparison Aspect | Traditional Time-Based Tool Change | AI-Predictive Tool Change |

|---|---|---|

| Decision Basis | Fixed schedule or production count, ignoring actual tool condition. | Real-time sensor data analysis to forecast remaining tool life. |

| Change Timing | Too early(tool is still usable=waste)or too late(tool is worn=part defects). | At the optimal point, just before performance drops. |

| Primary Outcome | High Cost: Tool waste+Quality risk | High Efficiency: Maximized tool use+Guaranteed quality |

| Visual Concept | ×Waste Zone(Too Early)→RiskZone(Too Late) | √Optimized Zone(Precise Change) |

Table 1: Graph comparing AI predictive maintenance vs traditional tool change schedules for CNC threading tools.

How Can Digital Twin Technology Simulate and Perfect Thread Machining Processes?

What if you could test and perfect a threading program without wasting a single piece of stainless steel? That is what could be possible using digital twin technology.

1. Virtual Validation Before Physical Cutting: This dynamic, virtual twin of your actual machining process simulates the operation, right from the CNC code and tool path down to material behavior and machine kinematics. The result? Engineers can catch potential problems, such as tool collision, chatter, or even minor dimensional inaccuracies, before any physical setup begins.

Reduce Setup Time and First-Article Scrap: By optimizing the process in the virtual environment, a machinist can significantly reduce machine setup time, while obtaining a right-first-time result on the first part. This is extremely useful when complex, high-value components are at stake and the cost of scrap is very high.

2. Real-World Application: One such use case is the simulation of machining a critical stainless steel valve body, whereby a digital twin was used by our engineers to identify the potential vibration during the final threading pass.They adjusted the tool support and cutting parameters in the simulation, eliminating the problem before it could occur on the shop floor, saving an estimated 15 hours of troubleshooting and rework.

Why Is AI for Quality Control Essential for Ensuring Thread Accuracy in High-Volume Production?

In a high-volume manufacturing environment, manual inspection of threads is slow, subjective, and prone to human error. AI-powered vision systems are redefining quality assurance.

1. 100%Inspection at Production Speeds

Advanced camera systems integrated with AI algorithms can perform 100% inspection for every thread produced, measuring key parameters like pitch, major diameter, and flank angles to micron-level accuracy in milliseconds.

2. Closed-Loop Feedback for Instant Correction

The true power of AI quality control comes in when the creation of a closed-loop system is possible. In the event of a deviation detection, the system can actually signal the CNC machine automatically to make compensatory adjustments for the next part so that a batch of non-conforming components are not produced.

We have explored the transformative impact this technology has in much greater detail in our guide to AI in precision machining. The resource explains how real-time data feedback is creating a new paradigm of zero-defect manufacturing. For a comprehensive foundation in core principles and techniques including traditional best practices that these AI strategies enhance, we recommend reading the ultimate guide to CNC stainless steel thread turning.

How do Smart Manufacturing Principles Transform Stainless Thread Production Efficiency?

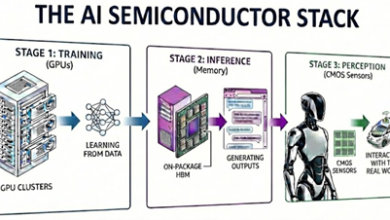

While these are individually powerful AI strategies, it is under the umbrella of Smart Manufacturing and Industry 4.0 that their full potential gets released.

Integration of AI parameter optimization, predictive maintenance, digital twin, and AI quality control on one data platform is what defines a truly smart factory. And the system ensures complete visibility into the production process, with insights gained in one area informing activities in another.

- Developing a Sustainable Competitive Advantage: The approach yields unparalleled efficiency gains-from less waste to lower energy consumption, and from reduced consumables to optimized resource use. A commitment to this philosophy, borne out in certifications like ISO 14001, proves indeed that peak efficiency and sustainability do go hand-in-hand. Seamless integration with new technologies means that getting familiar with a partner’s full spectrum of capability will be important for any manufacturer committed to building a future-proof operation-from advanced prototyping right through to high-volume production.

Conclusion

Mastery in stainless steel threading is less a matter of a machinist’s skill or good tooling than of intelligent technologies being leveraged to gain that decisive edge. AI-driven strategies discussed here, such as adaptive parameters, predictive maintenance, digital twins, automated quality control, and systemic integration, enable the manufacturer to make this journey from fighting costly rework to predictable premium-quality outcomes. Engaging in these approaches is not an upgrade but a strategic move toward leading the next generation of precision manufacturing.

FAQs

1. What is the single biggest challenge in stainless steel thread turning, and how can it be overcome?

A1: Work hardening generates the problem of rapid tool wear and poor surface finish. Solution: Premium coated tools should be used, such as TiAlN, ample coolant, with AI-optimized cutting parameters to maintain stable forces and avoid creating a hardened layer.

2. How do I select the right tooling for stainless steel thread turning?

A2: Selection based on material grade, type of thread, and volume. Key factors: substrate-prefer micro-grain carbide, coating-e. g., TiAlN, geometry. Predictive for high volume maintenance to monitor wear for scientific tool change scheduling.

3. How does Digital Twin technology help reduce setup time in thread machining?

A3: A Digital Twin virtually represents the process. It enables tests of CNC programs, fixtures, and toolpaths in advance to find collisions or issues. This cuts the debugging time on the machine and the inspection time, potentially reducing set-up by 50%.

4. What are the advantages of AI Quality Control over manual inspection for threads?

A4: AI offers superior speed, consistency, and accuracy. It enables 100% inspection at production speed, detecting minute deviations in pitch or form with repeatability to the micron level, suppressing human error and empowering corrections in real-time.

5. Will these AI strategies considerably raise production costs?

A5: Yes, there is an upfront investment, but evaluate based on total cost of ownership. Typically reducing scrap and prolonging tool life, along with maximising uptime, AI yields a really strong ROI. Preventing just one spindle crash through predictive maintenance can save more than the cost of the system.

Author Bio

Johnathan Crane is the Senior Manufacturing Consultant at LS Manufacturing. The company specializes in helping medical, aerospace, and industrial equipment OEMs overcome some of the most difficult precision machining challenges imaginable-be it mastering stubborn stainless steel threads or reducing rework costs-through its precision CNC machining services, sheet metal fabrication, and injection molding.Certified under AS9100D, ISO 9001:2015, and ISO 14001, this enterprise ensures that client projects achieve precision, reliability, and cost-effectiveness from prototype to production.