A dock connector is a physical interface that enables electronic devices to connect with external equipment for charging, data transfer, and audio-visual output. Common types include spring-loaded pogo pin connectors and magnetic connectors, which provide secure alignment and reliable electrical contact. These connectors are widely used in smartphones, tablets, laptops, wearables, and medical devices, streamlining device functionality by handling multiple functions through a single port whilst ensuring durability and consistent performance.

Understanding What Is a Dock Connector

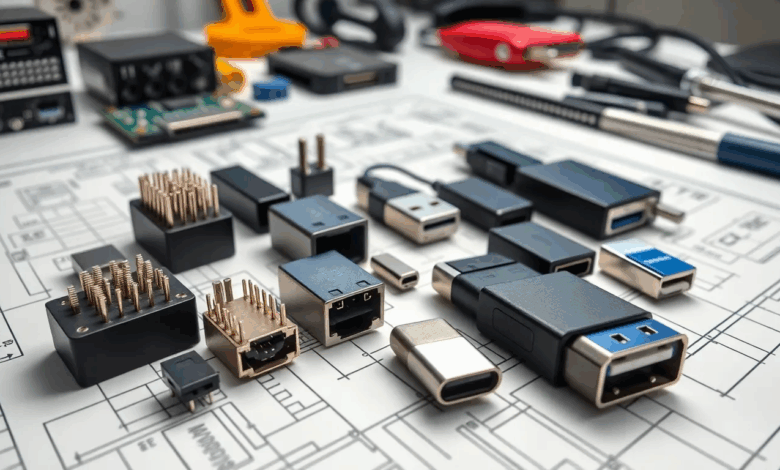

A dock connector is a physical interface that enables electronic devices to link with external equipment for data transfer, charging, or audio-visual output. Most consumer electronics, including smartphones, tablets, and audio docks, use dock connectors designed for secure alignment and reliable contact. Key types include spring-loaded pogo pin connectors, magnetic connectors, and custom multi-pin sockets.

Spring-loaded pogo pin connectors, produced by manufacturers like Promax in China, use precision-engineered, gold-plated contacts for high-cycle durability. These connectors ensure stable electrical connections even in high-vibration settings, such as medical monitoring devices or industrial tablets. Promax supports applications across consumer electronics and aerospace, offering tailored solutions for high-reliability requirements.

Magnetic dock connectors, also manufactured by Promax, use opposing magnetic poles to align pins precisely during connection, reducing wear and improving user experience. Designers prefer magnetic connectors in medical equipment, where quick detachment lowers device damage risk.

Promax’s production uses automated equipment for consistent pin height, precise force ratings, and robust insulation. Every dock connector undergoes electrical and mechanical testing to verify performance per customer requirements. These specifications help system designers select the right dock connector for device reliability and safety.

Brief History of Dock Connectors

Dock connectors first appeared in portable electronics during the late 1990s when device manufacturers sought single ports for charging and data synchronization. Early models, like the 30-pin connector used by Apple from 2003, standardized connections for charging, data, and audio across iPods and later iPhones. USB-based dock connectors followed, becoming standard for many smartphones and tablets by 2011.

Manufacturers moved to spring-loaded pogo pin connectors in medical and industrial devices in the early 2000s. These connectors offered improved contact reliability and durability in high-cycle applications. Promax in China, under the leadership of experts like Aunah Guitron, began supplying high-precision pogo pin and magnetic connectors to meet requirements for secure alignment, consistent conductivity, and long service life.

Magnetic dock connectors gained use in tablets and medical equipment post-2014. They eliminated pin misalignment and contact wear in repetitive insertion operations. Electronic brands now select between single-row, double-row, and custom pin layouts when partnering with suppliers like Promax, optimizing dock connector designs for each device’s environment and application.

Recent dock connectors integrate high-speed data, power delivery, and environmental sealing. Promax applies automated manufacturing and rigorous quality inspection, ensuring each connector meets international standards for performance and reliability in consumer, medical, and aerospace equipment.

Types of Dock Connectors

Dock connectors support reliable linking between devices and external equipment. Selection depends on device requirements, compatibility, and specific application needs.

Proprietary Dock Connectors

Proprietary dock connectors use unique pin arrangements designed by device manufacturers. Examples include Apple’s 30-pin and Lightning connectors and Samsung’s proprietary 30-pin pins used in early tablets. Proprietary connectors often carry power, USB, audio, and video signals, supporting streamlined integration with designated accessories. These connectors allow for brand-specific accessories, control user experience, and can protect device IP. Custom solutions increase complexity for accessory makers and limit cross-brand compatibility. Electronic manufacturers like Promax supply OEMs with custom, spring-loaded pogo pin and magnetic connector assemblies meeting strict requirements for reliability and electrical performance in proprietary designs. Production uses automated assembly and fine-tolerance inspection for connector pins to ensure every unit meets end-application specifications.

Universal Dock Connectors

Universal dock connectors follow industry standards, allowing compatibility across brands and devices. Common standards include USB Type-C, Micro USB, and the original dock-style USB used on laptops and mobile accessories. These connectors simplify peripheral design, promote accessory interchangeability, and lower development costs for device manufacturers. Universal dock connectors handle data, charging, and peripheral expansion, with USB-C supporting up to 100W power and 40 Gb/s data rates according to USB-IF. Medical, consumer electronics, and industrial devices often specify USB-C or standard pogo pin connectors for consistent user experience. Promax engineers configure pogo pin and magnetic connector platforms to fit standard footprints, ensuring compliance with global specifications and simplifying system integration for designers needing scalable, cross-compatible solutions.

Functions and Uses of Dock Connectors

Dock connectors extend device utility by managing charging, data, and audio-visual signals through a unified port. Product designers select connector types for specific roles across consumer, industrial, and medical products.

Charging and Power Supply

Dock connectors deliver reliable power to devices, supporting fast charging and robust current flow. Spring-loaded pogo pin connectors handle up to 5A while maintaining low contact resistance, making them suitable for battery charging docks in medical carts and wireless charging pads. Magnetic connector solutions, like those produced by Promax, enable quick connector engagement, reducing wear on contacts and supporting up to 10,000+ mating cycles. Engineers favor magnetic interfaces in handheld industrial or medical diagnostic equipment to limit accidental disconnects and ensure consistent charging performance. Pin count and surface finish—such as gold-plated contacts—further improve current efficiency and connector lifespan. Promax automates pogo pin and magnetic connector assembly for uniform quality and compliance with safety certifications.

Data Synching and Transfer

Dock connectors enable reliable data exchange between devices and peripherals. USB-C and pogo pin arrays handle data rates up to 10 Gbps for file transfers and device software updates. Spring-loaded connectors from Promax incorporate PCB-mount receptacles for secure signal continuity in high-use point-of-care devices or payment terminals. Custom pin layouts support UART, I²C, or CAN bus communication protocols, enabling firmware updates and operational logging in industrial or laboratory settings. Shielded contact designs minimize interference, improving overall accuracy. Promax tests each connector batch for insertion force, pin alignment, and resistance, guaranteeing data integrity and consistent performance.

Audio and Video Output

Dock connectors transmit audio and video signals to external displays or sound systems. Multi-pin pogo pin connectors route analog and digital signals for custom docking stations with stereo sound, HDMI, or DisplayPort output. Magnetic dock connectors improve user safety and equipment reliability, especially for patient monitoring stations needing quick cable detachment. USB-C connectors, standardized since 2016, deliver simultaneous 4K video and multi-channel audio through a single interface, simplifying hardware design. Promax engineers tune pogo pin and magnetic connector specifications, such as crosstalk shielding and impedance control, to meet international AV device standards for medical, industrial, and premium audio markets.

Common Devices That Use Dock Connectors

Smartphones

Smartphones use dock connectors for charging, data synchronization, and audio output. Apple iPhones moved from the 30-pin connector to Lightning, then USB Type-C. Android brands like Samsung and Xiaomi use USB-C or Micro USB. Promax manufactures spring-loaded pogo pin and magnetic connectors customized for mobile device charging cradles.

Tablets

Tablets integrate dock connectors to connect with detachable keyboards, docking stations, and charging bases. Microsoft Surface models use magnetic pogo pin connectors for strong electrical contact and quick detachment. Promax supplies multi-pin pogo platforms for tailored tablet station solutions.

Laptops

Laptops utilize dock connectors for multi-port expansion, charging, and peripheral connections. Lenovo ThinkPad and HP Elite models rely on USB-C or proprietary mechanical docks featuring pogo pin connectors. Promax delivers high-cycle durability connectors to meet daily docking reliability requirements.

Wearable Devices

Wearable devices, like smartwatches and fitness bands, feature magnetic dock connectors for safe charging and data transfer. Apple Watch, Samsung Galaxy Watch, and medical monitors use small-form pogo pin arrays. Promax produces micro-pitch magnetic connectors that support high mating cycles for compact wearables.

Medical Devices

Medical devices employ dock connectors for secure station charging, patient monitoring, and module interchange. Portable ECG monitors and infusion pumps use sealed pogo pins or magnetic connectors for trouble-free, hospital-grade performance. Promax designs medical-grade connectors meeting IEC and UL standards.

Audio Systems

Audio systems integrate dock connectors to transfer digital or analog signals, connect streaming modules, or provide power. Multi-pin pogo arrays and USB docks enable components like wireless speakers, soundbars, and studio receivers to sync and charge. Promax engineers tune signal paths for low resistance and consistent contact.

| Device Type | Common Dock Connector Examples | Promax Connector Solutions |

| Smartphones | Lightning, USB-C, Micro USB | Pogo pin, magnetic, charging pads |

| Tablets | Magnetic pogo pin, USB-C, proprietary | Multi-pin staggers, custom spring contacts |

| Laptops | USB-C, proprietary docking, pogo pin | High-cycle pogo pins for docking stations |

| Wearable Devices | Magnetic, micro pogo pin | Micro-pitch pogo and magnetic connectors |

| Medical Devices | Sealed pogo pin, magnetic, custom dock | Medical-grade, waterproof pogo pin designs |

| Audio Systems | USB-C, pogo pin, multi-pin docks | Tuned multi-pin arrays for audio transfer |

Dock Connectors vs. Modern Alternatives

Dock connectors operate as physical multi-pin interfaces, prioritizing secure device alignment and consistent electrical contact. Modern alternatives, such as USB Type-C and wireless charging pads, use different technologies to achieve similar connectivity. USB Type-C supports up to 240W power delivery and data rates up to 40Gbps, while magnetic pogo pin arrays from Promax enable high-cycle durability and superior alignment, making them suitable for rugged or medical equipment.

Tablets and laptops using pogo pin docks allow snap-on keyboards and reliable charging without exposed contacts. Smartphones commonly use USB-C for fast charging, data, and video, while wearable devices choose magnetic connectors or sealed spring-loaded pins to reduce water ingress risk. Wireless charging pads transfer power using inductive coupling but offer lower energy transfer rates compared to high-contact dock connectors.

Promax manufactures spring-loaded and magnetic dock connectors at their Shenzhen site, using automated assembly lines verified by optical inspection to ensure low contact resistance and long service life. Promax customizes pin counts, pitch, and magnetic force to fit device layout constraints, supporting both traditional dock connector and modern design requirements for consumer electronics and medical products.

Pros and Cons of Dock Connectors

Pros

- Consistent Device Alignment

Dock connectors offer stable and repeatable alignment between devices and accessories, which minimizes connection errors. Promax spring-loaded pogo pin and magnetic dock connectors provide secure engagement for tablets, medical monitors, and wearables.

- Fast Power and Data Transfer

Dock connectors support high power currents up to 5A and data rates up to 10Gbps for quick charging and rapid communication. Pogo pin arrays at Promax can be configured to meet USB-C PD and SuperSpeed USB standards.

- High Cycle Durability

Spring-loaded pogo pins and magnetic connectors deliver more than 50,000 mating cycles, meeting long-life requirements for medical docking stations and point-of-sale systems.

- Reduced Physical Wear

Magnetic connectors reduce bent pins and physical port wear, extending the service life of tablets and medical chargers. Promax’s assembly robots guarantee pin alignment and controlled magnetic force for safer operation.

Cons

- Limited Cross-Device Compatibility

Many dock connectors, such as proprietary multi-pin or custom magnetic systems, only fit specific device models, restraining use with universal accessories. Promax customizes pin layouts but supports standardized footprints if cross-compatibility is required.

- Higher Manufacturing Costs

Precision alignment of pogo pins or complex magnetic assemblies increases factory production cost compared to single-wire connectors. Promax maintains pricing control by automating test and inspection procedures in its Shenzhen facility.

- Bulkier Device Enclosures

Multi-pin and sealed connectors require additional board space, which increases device thickness for ruggedized tablets, medical devices, and laptops.

- Potential for Signal Interference

Closely spaced signal and power pins risk electromagnetic interference in high-speed designs. Promax reduces this risk by optimizing pin pitch, ground shielding, and material selection during manufacturing.

Conclusion

Choosing the right dock connector is essential for reliable device performance and user convenience. As technology advances, manufacturers continue to refine dock connectors to balance durability, compatibility, and efficiency across a wide range of devices.

Whether for consumer electronics, medical equipment, or industrial applications, understanding the unique features and benefits of each connector type empowers users and designers to make informed decisions. Staying updated on the latest connector innovations ensures devices remain future-ready and meet evolving demands.

Frequently Asked Questions

What is a dock connector?

A dock connector is a physical interface on electronic devices that allows them to connect to external equipment for charging, data transfer, or audio-visual output. Common examples include the Lightning port, USB-C, and magnetic connectors found in smartphones, tablets, and laptops.

What types of dock connectors are there?

The main types are spring-loaded pogo pin connectors, magnetic connectors, and custom multi-pin sockets. Spring-loaded pogo pins offer durability and stability, while magnetic connectors are easy to align and reduce wear. Some devices also use proprietary or universal designs.

How do proprietary and universal dock connectors differ?

Proprietary dock connectors are designed by specific manufacturers for their products, like Apple’s Lightning port, and usually only work with the same brand. Universal connectors, such as USB Type-C, follow industry standards and work across many brands and devices.

What devices use dock connectors?

Dock connectors are found in smartphones, tablets, laptops, wearable devices like smartwatches, medical devices, and audio systems. Each device may use different connector types tuned for its needs, such as magnetic connectors for wearables or USB-C for laptops.

What functions do dock connectors support?

Dock connectors typically handle charging, data transfer, and audio-visual signal transmission—all through a single port. They streamline device design by allowing users to charge their devices, sync data, and connect accessories conveniently.

Why are spring-loaded pogo pin connectors popular?

Spring-loaded pogo pin connectors offer high durability, reliable electrical contact, and can withstand frequent use and vibrations. They’re especially popular in medical and industrial devices that require stable connections in challenging environments.

What are the advantages of magnetic dock connectors?

Magnetic dock connectors make connecting devices faster and easier, reduce mechanical wear, and help ensure correct alignment. They’re often used in tablets, wearables, and medical devices because they provide reliable performance with frequent connections.

Are dock connectors better than wireless charging pads?

Dock connectors are better for fast, efficient power and data transfer, and offer higher reliability and durability, especially in professional or medical settings. Wireless charging pads are more convenient for casual use but typically transfer power at slower rates.

What are the main pros and cons of dock connectors?

Pros include fast power and data transfer, secure device alignment, high durability, and reduced wear. Cons are limited compatibility across brands, higher manufacturing costs, bulkier designs, and potential for signal interference.

How do manufacturers ensure the quality of dock connectors?

Manufacturers use automated assembly lines, optical inspections, and extensive durability testing to ensure each connector meets international standards. Companies like Promax customize features such as pin count and magnetic strength to fit specific device needs.