The next predicament that most maintenance groups face regularly concerns the order in which activities should be dealt with first. Work orders tend to accumulate and the establishment of priorities can easily be skewed by individual preference and convenience such that the critical need may fall by the wayside. A computerized maintenance management system, or CMMS, may be used to add order to this chaotic process. Nonetheless, although highly sophisticated tools have been established, human judgment can influence the choices. The trick is adapting how to use the system to show priority based on data and not a preference.

The Importance of Clear Priority Standards

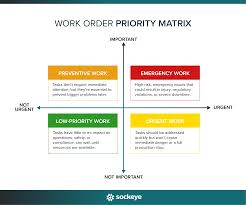

To have things function effectively in maintenance scheduling there must be uniformity in definition of priority regarding the high, medium, and low. In absence of these guidelines, technicians or managers can arbitrarily attain values depending on their own view rather than operational requirements. Lack of clarity in such cases normally leads to less serious problems being given urgent priority at the expense of more important assets. Developing standards as written and consistent with institutional objectives is a way of ensuring transparency in the process.

When such standards have been agreed by the team they decrease unnecessary discussion and promote accountability. No one can miss an explanation why a particular job is termed an urgent one or a routine one. This common ground is particularly significant when the various departments are making requests. By eliminating personal judgment in this process the CMMS could be set up to automatically enforce these standards to be applied in a consistent manner to all new work orders.

The Role of Asset Criticality

Prioritization must always take into consideration the necessity of an asset to company undertakings. A less serious fault in a backup unit is not urgent as compared to the similar fault in a machine which runs daily production. The assessment of the asset criticality in advance enables the CMMS to pre-populate that in the scheduling consideration. It is less prone to bias since much attention is paid at all times to the most effective ones.

After assets are categorized, CMMS may be able to put weighted value on distinct types of failure. As an example, anything that potentially poses safety risk on a key machine will take priority by far as compared to a cosmetic enquiry upon a less important machine. The less these parameters are set in advance, the more there is always space to have the subjective decisions made when other requests are coming in the system.

The Value of Data Driven Decision Making

CMMS software has reporting capabilities that point out the past trends like frequency of downtime, repair costs, and labour hours. These measures assist the maintenance leaders in the identification of the areas of resource allocation most effective. With the help of these data, the work orders will be prioritized less likely to be based on favoritism or habits.

Using this data also builds credibility with senior management. Rather than trusting their intuition, managers of maintenance will be able to justify the movement of one order ahead of another based on evidence provided by the system. This does not only remove any bias but also builds confidence with regard to the approach of the maintenance department. In the longer run, a data-driven approach renders the whole work order process more predictable and defensible.

The Importance of Regular Review

The finest set ups in work order management software need constant scrutiny. Businesses evolve, assets get replaced and new compliance is introduced. Teams do not review their methods of setting priorities and risk slipping back into old habits where bias comes back into play. Maintaining an audit maintenance interval of priority settings will guarantee a fit of priority settings with the changing objectives.

These appraisals are to have the contribution of the technicians and managers. As technicians are frequently on the front line, so to speak, they witness first-hand how priority levels affect the day-to-day operation process, and managers are able to assess whether the results line up with the overall company objectives. This level of cooperation is effective because it prevents any changes in the system that might form loopholes and lead to personal judgment to dominate over the set standards.

A bias in work order prioritization can compromise workplace safety, reliability of the assets, and workplace efficiency. Organizations can achieve objective scheduling by establishing definitive criteria, establishing asset criticality, data-driven choice of options and regularly monitoring system defaults. The outcome is that the most vital work is prioritized and is taken care of first not because it has a powerful request but because the system shows this to be most vital.