In the world of precision engineering and advanced manufacturing, even the smallest details can determine the success of a product. One such detail is the cutting and shaping of tubes—a process that plays a critical role in industries ranging from aerospace and automotive to medical devices and energy systems. Modern tube cutting technology has advanced dramatically in recent years, delivering a combination of speed, accuracy, and consistency that traditional methods simply cannot match.

The Growing Importance of Tube Cutting

Tubes are fundamental components in countless applications. They are used for fluid transport in hydraulic and pneumatic systems, structural integrity in aircraft and vehicles, and precision conduits in medical instruments. Because of their widespread use, the ability to cut tubes to exact specifications is central to ensuring product quality, safety, and performance.

Traditional cutting methods—such as manual saws or abrasive tools—often resulted in burrs, uneven edges, and dimensional inaccuracies. For industries that require high tolerances, these limitations created significant challenges. Today’s tube cutting technologies, however, address these issues head-on by combining automation, computer control, and advanced cutting methods.

Key Innovations in Modern Tube Cutting

1. Laser Tube Cutting

Laser-based systems have become the gold standard for high-precision applications. Using computer numerical control (CNC), lasers can cut complex shapes, holes, and slots directly into tubes with exceptional accuracy. They deliver smooth edges without burrs and reduce the need for secondary finishing processes.

· Advantages: High precision, speed, and the ability to handle intricate designs.

· Applications: Aerospace structural components, automotive exhaust systems, and medical-grade instruments.

2. CNC Tube Cutting Machines

Computer-controlled machines have replaced manual approaches in many sectors. CNC tube cutters use rotating blades, lasers, or water jets under precise digital control, ensuring repeatability and consistent output across high-volume production runs.

· Advantages: Automation, reduced human error, and improved efficiency.

· Applications: Mass production in automotive, heavy machinery, and consumer goods.

3. Abrasive Water Jet Cutting

For materials that are sensitive to heat, water jet technology provides a non-thermal cutting process. High-pressure streams of water mixed with abrasives cut through metals, composites, and ceramics without altering their structural properties.

· Advantages: No heat-affected zones (HAZ), suitable for exotic materials.

· Applications: High-performance aerospace materials, energy pipelines, and specialized industrial equipment.

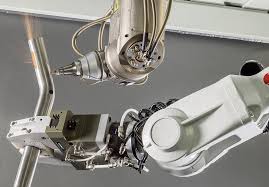

4. Advanced Clamping and Fixturing Systems

To achieve precise cuts, modern tube cutting systems use advanced clamping mechanisms that hold tubes securely in place. This minimizes vibration, improves accuracy, and reduces tool wear.

The Role of the Tube Cutter

At the core of these technologies is the tube cutter itself. Whether it’s a precision laser, a CNC-controlled blade, or a water jet nozzle, the cutting tool determines the final quality of the component. Modern cutters are engineered to handle a variety of materials—steel, aluminum, titanium, composites—with high durability and adaptability.

Sophisticated tube cutters also integrate with CAD/CAM software, allowing engineers to design complex parts digitally and translate them directly into manufacturing processes. This digital workflow ensures that prototypes and production runs meet exact specifications with minimal waste.

Benefits for Precision Engineering and Manufacturing

The integration of advanced tube cutting technologies brings multiple benefits to industries that demand precision:

· Higher Accuracy: Achieving tolerances within microns for critical applications.

· Reduced Waste: Optimized cutting paths and automated nesting minimize material loss.

· Faster Production: Automation enables higher throughput without sacrificing quality.

· Versatility: Capable of handling different diameters, thicknesses, and materials.

· Lower Costs: Reduced labor requirements and fewer secondary finishing processes.

For industries such as aerospace, where safety and precision are non-negotiable, or medical device manufacturing, where components must meet stringent regulatory standards, these benefits are transformative.

Looking Ahead: The Future of Tube Cutting

The next wave of advancements is focused on further automation, integration, and intelligence. Future systems are likely to feature:

· AI-driven optimization: Predictive algorithms that adjust cutting parameters in real time.

· Smart monitoring: IoT-enabled cutters that report performance, wear, and maintenance needs.

· Hybrid technologies: Combining laser and water jet cutting for greater flexibility.

· Sustainability focus: Energy-efficient machines designed to reduce environmental impact.

As manufacturing shifts toward Industry 4.0, tube cutting will become increasingly interconnected with other processes, creating fully automated, digital production lines that maximize efficiency and precision.

Conclusion

Modern tube cutting technology is reshaping the landscape of precision engineering and manufacturing. From advanced laser systems to CNC-controlled machines, innovations are enabling faster, more accurate, and more cost-effective production. At the heart of this progress lies the evolution of the tube cutter, which has transformed from a basic manual tool into a sophisticated, digitally integrated system.

As industries demand ever greater precision and efficiency, these technologies will continue to evolve—ensuring that tube cutting remains a cornerstone of modern engineering excellence.