Around one in six UK organisations have embraced AI, according to research carried out by the Department for Digital, Culture, Media & Sport.

The technology is helping many industries drive greater efficiency and productivity, improving everything from common processes to detailed data analysis and effective planning.

One such industry is construction. Traditionally a slow-moving industry when it comes to adopting new technologies, AI is making its mark in this segment, helping to deliver significant time and cost savings across major projects.

The potential is huge; it has been estimated that the construction industry can accrue more than £1 trillion in savings if modern technologies such as AI are adopted to boost productivity.

The impact of generative AI

Rising to fame in 2023 through tools like ChatGPT, Bard and Midjourney, generative AI creates new content based on the dataset that it has been given.

A step above traditional AI systems that use machine learning to analyse and predict patterns, generative AI can review vast quantities of unstructured data to come to its conclusions. For construction, this could include areas like build methodology, performance benchmark information, or even relatively simple things like inventory management.

However, if everyone is using the same dataset, creativity and uniqueness become a thing of the past. And, because these tools are based on large, deep learning models trained on vast quantities of unstructured, unlabelled data, they can only give general answers based on past data. It means that suggestions are not necessarily going to be relevant to the project in question.

By avoiding the generalist tools, like ChatGPT, and instead using AI tools that work from information that users provide directly, such as P6 and BIM models, project teams can confidently rely on the validity of the information that is being used to model different scenarios.

Reducing the risk factor

According to McKinsey research, 98% of ‘megaprojects’ are delayed or over budget. Reducing this risk and improving the opportunities for project recovery are essential for the industry to improve.

The number of extremely hot days in the UK are predicted to increase four-fold, with days exceeding 25 degrees Celsius rising from around 10 to 37 days per year. Extreme heat can make materials unusable, causing significant project delays. Metal materials, like rail tracks, can warp out of shape, making them unsafe. Bricks can also become too dry, leading to weak masonry and a reduction of the standard of the final building.

AI can even help here. Project managers can use software to create extreme weather contingency plans, based on previous years, to proactively find a solution before delays occur. This process can significantly reduce the risk of downtime, as thousands of alternative solutions can be assessed and the most effective one chosen ahead of time.

Understanding resourcing

By adding various constraints, including specific challenges like labour availability, project managers can test different scenarios to see how they will influence the project delivery date and costs.

Equipment and materials are also very specialised in many construction sites. As a result, the lead times for products can be a one or two year wait. If these parts are even a few days late, this can unexpectedly impact schedules. Exploring these different scenarios through construction optioneering will lead to schedules that can be both more efficient and less risky.

René Morkos, CEO at ALICE Technologies, explained: “It is all about adding transparency and making scheduling data more accessible, allowing project teams to consider more options and pick the right solution to drive better outcomes for the project. By inputting specific data, the solutions are tailored to each project and also repeatable for similar projects in the future.”

Products leading the way

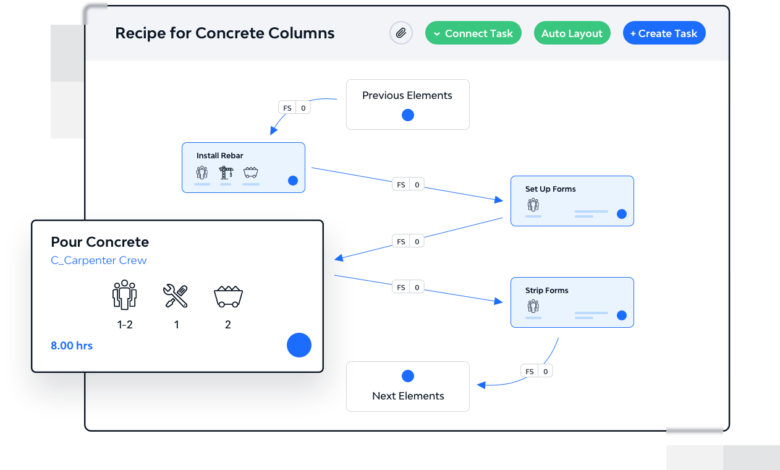

There are tried and tested AI-powered platforms available that can perform accurate calculations in seconds and offer more efficient construction programmes, with less risk, lower costs and waste reduction.

These technologies allow project managers to import P6 models and test multiple scenarios to create highly efficient solutions that can be adjusted as needed during construction.

project managers can also connect their existing 3D models with their schedule and estimates to visualise all aspects of their project in 4D. This allows the visual design to be shared with stakeholders more easily.

To maximise the rollout of AI software in the construction industry, integrating processes with traditional methods and allowing users to enhance these methods is a simple way to encourage further adoption.

René continued: “Construction is often highly inefficient. During my time in the field as a civil engineer, the inefficiencies of construction projects were clear: only around 3% of the construction site is worked on at any one time, and you see many examples of labour and resources being mismanaged. For projects with an already low margin, this has a significant impact on profits.”

AI project management tools have been proven to help to boost profits by an average of 91%. In an industry that has small margins, this can be the difference between a business investing in new technologies in the future and having a healthy margin or losing the race against competitors.