Manufacturing globally has faced a turbulent few years, with rising geopolitical tensions, soaring costs, and supply chain disruptions, now compounded by a new era of trade wars among major economies. All these elements are forcing countries here in the West to rethink their dependence on offshore production. The reshoring of manufacturing, bringing production back to domestic markets has very much re-emerged as a strategic priority, but the cost and labour advantages – that drove industries to offshore production in the first place – remain a challenge.

However, AI-powered automation is now rapidly helping to change that equation, so much so that the World Economic Forum recently deemed embodied AI to be the next frontier in manufacturing. By deploying AI agents across factory floors, manufacturers can reduce inefficiencies, lower operational costs, and enhance workforce productivity, making domestic production much more competitive. In a global economy increasingly shaped by tariffs and economic nationalism, AI could be the catalyst that enables Western nations to build resilient, cost-effective and scalable manufacturing capabilities at home.

The economic case for reshoring manufacturing

The push for reshoring is not just a political talking point—it has real economic drivers. Globally, manufacturing losses amount to an estimated $1 trillion annually due to inefficiencies, waste, and supply chain disruptions. As businesses recover from the pandemic’s supply chain shocks, raw material costs continue to rise, and both investors and consumers increasingly prioritise sustainability. This level of inefficiency is not sustainable long-term for businesses that want to remain competitive.

Additionally, governments are the ones who often suffer reputationally from costly delays, shortages, and price hikes. This is leading to governments offering incentives to rebuild domestic supply chains, particularly in strategic industries like healthcare.

AI-Powered digital workers

One of the key concerns about reshoring is workforce availability. In many Western markets, labour shortages in the manufacturing sector pose a challenge to scaling up domestic production. AI agents—digital workers that operate alongside human employees—are already being deployed to bridge this gap.

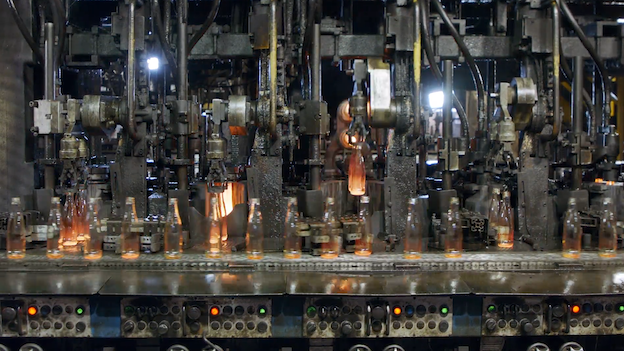

Unlike traditional automation, AI-driven systems adapt to real-time production data, dynamically optimising workflows and detecting inefficiencies. For example, AI-powered video solutions, like Cerrion, can monitor production lines using existing CCTV infrastructure, identifying inefficiencies, faults, or irregularities as they happen. They can detect anomalies, such as fallen objects on the line, automatically stopping production and alerting operators before issues escalate. By identifying problems early, manufacturers can reduce waste, minimise downtime, and prevent costly production losses.

Improved workplace safety

Beyond efficiency, AI also enhances workplace safety by reducing reliance on human monitoring in hazardous environments. Automated monitoring systems provide continuous oversight, helping to prevent accidents and improve Health, Safety, and Environmental (HSE) compliance. Additionally, these AI-driven systems can pinpoint material mishandling, detect bottlenecks, and identify process deviations more efficiently than human operators, allowing manufacturers to optimise resources, improve quality control, and drive more sustainable operations.

Overcoming cost barriers with AI workers

For many manufacturers, cost remains one of the biggest barriers to reshoring. Offshore manufacturing continues to be attractive due to lower labour costs, economies of scale, and well-established production hubs. This is why agentic AI is a game-changer. Its affordability.

The advantage of AI-driven systems, such as those outlined above, is their ability to integrate seamlessly with existing factory infrastructure, making implementation cost-effective without the need for large-scale overhauls.

AI-driven production systems can also automate repetitive tasks, reducing reliance on low-cost labour while maintaining high levels of productivity. AI-powered digital workers therefore present a tangible solution for manufacturers looking to improve productivity and resilience.

Using AI to build sustainable manufacturing

In an era where environmental concerns and economic security are equally important, AI can also help manufacturers work towards their sustainability goals without compromising profitability. From the top down, governments and regulatory bodies are increasing pressure on manufacturers to reduce emissions, improve resource efficiency, and minimise waste. Whilst for consumer-facing brands, consumers are increasingly seeking out more sustainable brands.

Energy efficiency: Smart AI-driven systems can optimise energy usage, analysing energy consumption patterns and automatically adjusting operations to reduce waste and lower costs. By implementing AI at scale, manufacturers can offset the traditionally higher labour costs associated with domestic production, making reshoring a more viable and competitive alternative to offshore manufacturing.

Carbon footprint reduction: AI-driven logistics can streamline supply chains, reducing transportation-related emissions and improving overall sustainability.

Waste reduction: AI-powered quality control systems identify defects early, minimising material waste and production errors.

Lowering barriers to AI adoption in manufacturing

Despite AI’s potential, many manufacturers hesitate to adopt it due to concerns about legacy infrastructure, cost, and trust in automated decision-making. However, recent advancements have made it significantly easier to integrate AI into existing manufacturing systems without requiring massive overhauls. The key to successful AI adoption lies in a phased and strategic approach that ensures both efficiency gains and minimal disruption to operations.

One of the most effective ways to introduce AI into manufacturing is through gradual implementation. Rather than overhauling entire production lines, manufacturers can start with targeted deployments in areas such as process or quality control. These focused applications allow companies to see immediate value, demonstrating AI’s ability to reduce downtime, improve product consistency, and optimise operational efficiency before scaling the technology further.

Building trust in AI is also crucial, which is why explainable AI is becoming a key factor in adoption. Transparent AI models provide clear insights into how decisions are made, allowing manufacturers to better understand and validate AI-driven recommendations. By maintaining human oversight and ensuring that AI systems operate within predefined parameters, manufacturers can improve confidence in automation while retaining control over critical production processes.

Scalability is another essential consideration. Today’s AI solutions are designed to integrate seamlessly with existing factory infrastructure, meaning manufacturers can deploy high-impact automation without the need for significant capital investment. This accessibility is making AI adoption more viable for businesses of all sizes, allowing them to reap the benefits of increased efficiency, reduced waste, and improved competitiveness in a rapidly evolving industrial landscape.

What’s next for AI in manufacturing?

AI offers the technological backbone to make the reshoring of western manufacturing not only possible, but also cost effective. By embracing AI-driven automation, manufacturers can bring production closer to home, reduce reliance on volatile global supply chains, and build resilient, efficient, and competitive operations for the future.

AI is no longer a futuristic concept; it is very much a practical tool that is already delivering results.