Speed and adaptability are important in robotics development. Engineers and product teams face pressure to test and refine designs quickly without compromising precision. In this environment, additive manufacturing, often referred to as 3D printing, has become an essential tool. By allowing teams to create custom parts on-site or on demand, 3D printing supports rapid iteration, quick validation, and reduced risk throughout the robotics development cycle.

The process of building a robotic system involves more than code and sensors. Functional prototypes, testable enclosures, structural components, and mounts all need to be evaluated in real-world conditions. Traditional manufacturing often cannot keep up with this pace, especially in the early stages of design. With additive manufacturing, development teams can shorten turnaround times while maintaining tight control over both design and materials. You can learn more about the range of 3D printing technologies available at https://www.upsideparts.com/3d-printing

Faster Iteration in the Early Stages

Building early models of robotic systems often requires experimentation. Joints need to be adjusted, arm lengths revised, and component placements tweaked based on test results. Each of these changes would require a new mold or custom machining if handled by traditional processes. That is expensive and slow.

3D printing eliminates that barrier. A revised CAD file can be sent directly to a printer. Parts can be printed overnight, tested the next day, and updated again without outside vendors or long waits. This quick loop of design, testing, and revision helps robotics teams catch issues early and refine their designs without the delays of conventional tooling.

Functional Testing with Accurate Parts

When testing a robotic design, accuracy matters. A poorly fitted enclosure or oversized joint can throw off results or introduce problems that were not part of the original design. 3D printing, especially with resin technologies, offers precision and surface quality that allow for reliable testing without waiting for final production methods.

This is useful not only for concept evaluation but also for validating how the design holds up in simulated or real environments. Whether it is a wearable robot part that must fit the human body or a structural frame used in field conditions, 3D printed parts provide the confidence needed to move to the next stage. For more detail on how resin printing can support high-detail applications, visit https://www.upsideparts.com/3d-printing/standard-resin

Customization for Specialized Systems

Many robotics projects do not involve high-volume production. Instead, they focus on highly specific applications that require unique part shapes or low-run builds. 3D printing makes it easier to create components that match specific design needs without being tied to off-the-shelf parts or molds.

This customization allows robotics teams to design parts that reduce weight, fit unusual geometries, or integrate functions like cable management into structural pieces. It also supports experimentation with different materials to test performance, flexibility, or resistance to impact and heat.

Simplifying the Transition to Production

Moving from a prototype to a functional system often requires small production runs or bridge manufacturing. In the case of robotics, that might mean ten or twenty working units for pilot projects, field testing, or demonstration. 3D printing makes this step more straightforward, since it allows teams to continue using the same designs and materials developed during prototyping, without scaling up to full factory tooling.

By using additive manufacturing during this phase, teams maintain control over production without committing to expensive or inflexible methods. The consistency between prototype and field unit also makes it easier to track performance and reliability.

Supporting Innovation Across the Robotics Field

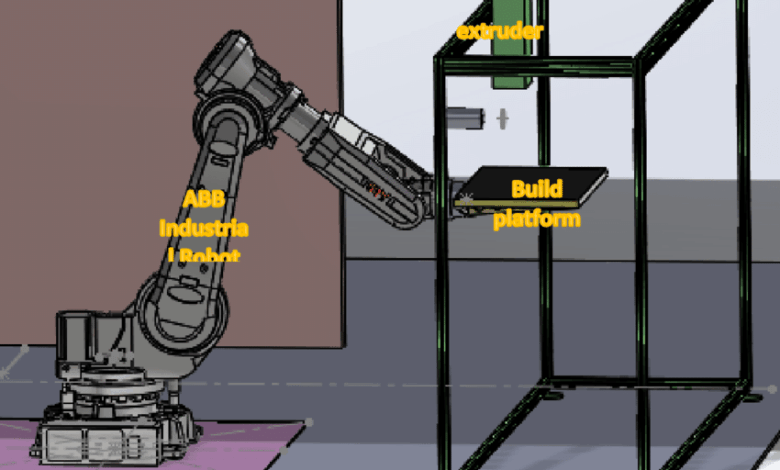

As more robotics applications emerge in sectors like healthcare, logistics, agriculture, and manufacturing, 3D printing offers a consistent advantage. Whether teams are building automated arms, service robots, or autonomous platforms, the ability to test and revise components in-house, often within hours, gives developers the edge they need to keep moving.

Additive manufacturing does not replace all other production techniques. But it does remove many of the common bottlenecks that slow down early design and field testing. In doing so, it supports faster innovation, reduces waste, and helps robotics concepts become reality with fewer delays.