— Breakthrough tray-control technology sets a new performance benchmark for high-volume ground-meat production –

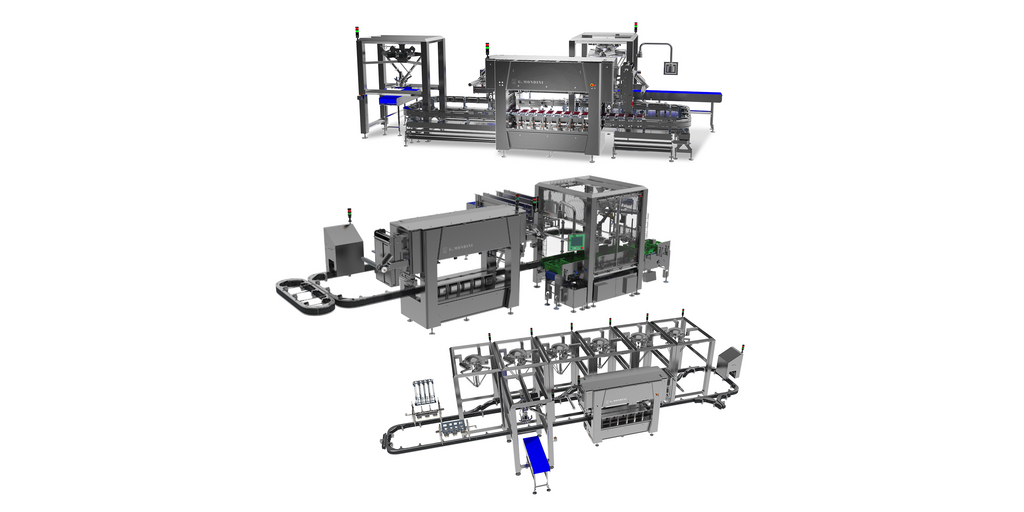

TAUNTON, Mass.–(BUSINESS WIRE)–#automatedpackaging–Harpak-ULMA announced a new application of the Mondini Trave Sinfonia® tray-sealing platform designed explicitly for high-volume ground-meat production. The solution delivers a higher-output, fully automated alternative to conventional tray-sealing methods — setting a new performance benchmark for producers.

Sinfonia can effectively double throughput compared to typical mechanical grind-line tray sealers, increasing output from roughly 120 packs per minute to as high as 200 packs per minute. Sinfonia’s software-controlled magnetic-transport architecture delivers this dramatic performance advantage by moving trays on independent shuttles with micron-level accuracy. The innovative design eliminates belts, pusher arms, and other friction-based components that typically constrain sealing speed, especially in low-oxygen MAP applications.

Although the Sinfonia system was introduced in 2023, this marks its first application for grind-line environments, where tray control, contamination, and mechanical indexing have long limited achievable speeds.

“The competitive ceiling for grind-line tray sealing is around 120 ppm. With Sinfonia, we can engineer a 200-ppm grind line—almost a 100% throughput increase,” said Carlo Bergonzi, Product Manager, Tray Sealing at Harpak-ULMA. “Sinfonia fundamentally changes what’s possible in ground-meat tray-sealed packaging,” he added. “By controlling each tray independently, we remove the mechanical constraints that typically dictate line speed. The result is a faster, cleaner, and far more stable tray-sealing process that simply isn’t achievable with conventional systems. Given the momentum behind meat-brick formats across major retailers, this application directly addresses the performance conversations we’re hearing from processors as they head into IPPE 2026.”

The new configuration integrates portioning, dual denesting, retractable conveyor loading, and a 14-up sealing array — enabling each processing station to run at its optimal rate without being limited by fixed-pitch conveyor mechanics. With the new Sinfonia application, producers gain a consistent, contamination-resistant tray path and simplified changeovers in a compact footprint. In contrast, competitive systems rely on mechanical indexing systems that cannot independently control tray motion. Comparable throughput levels are not currently achievable using traditional technologies.

For more information, visit www.harpak-ulma.com/equipment/trave-sinfonia/ or call (508) 884-2500. Experience a live demonstration at one of Harpak-ULMA’s Customer Experience Centers in Boston, Atlanta, or Costa Mesa, Calif. —call (508) 884-2500 to make arrangements. Visit Harpak-ULMA at IPPE, Jan. 27–29, 2026, in Atlanta at Booths BC43109 & BC45111.

About Harpak-ULMA

Harpak-ULMA Packaging is the North American arm of ULMA, a $1B industry leader in complete automated packaging line solutions for food, medical, and industrial products. Harpak-ULMA provides smart, connected packaging systems, including tray sealing, thermoforming, horizontal ffs, vertical ffs, flow wrapping, multihead weighing, robotic loading and unloading systems, metal detection, x-ray, checkweighing, labeling, vision inspection, cartoning, sleeving, case packing, and palletizing. These systems form the backbone of complete, integrated lines that reduce customers’ total cost of ownership, address the challenges of an aging, scarce workforce, and improve maintenance and operations via Harpak-ULMA’s extensive service offerings, 24/7 support, and competitive parts sourcing with same-day shipping. In addition, Harpak-ULMA represents G. Mondini tray sealers and Cabinplant’s advanced weighing systems and complementary processing solutions in the United States and Canada. Since joining the Rockwell Automation Partner Network in 2018, Harpak-ULMA has leveraged Rockwell’s controls and information platforms to deliver greater efficiency, uptime, throughput, and package quality — while reducing waste.

Contacts

Joshua Allen at [email protected]