For decades, supply chain systems have been adept at telling you what happened. A shipment was delayed. A component went out of stock. A supplier failed to meet a delivery date. These descriptive analytics have been useful for reporting and accountability, but they rarely prevent the next disruption.

Some systems moved into diagnostic analytics, explaining why an event occurred. For example, due to a shipping route issue, a production shortfall, or a surge in demand. This context is valuable, but it still arrives after the fact.

In an environment where disruption is constant and lead times are shrinking, “what” and “why” are no longer enough. The next frontier is prescriptive analytics. These systems go beyond reporting on the past or explaining the present. They recommend the best course of action and surface it in time to act.

What Prescriptive Analytics Looks Like

Prescriptive analytics uses AI and advanced modeling to simulate scenarios, evaluate trade-offs, and propose optimal actions. In manufacturing, this could involve identifying the most cost-effective supplier mix for an upcoming build by factoring in price trends, geographic risk, and lead-time reliability.

In logistics, it might involve dynamically re-routing shipments in response to weather disruptions or port congestion. In procurement, it could mean proactively sourcing alternate components when early warning signs of a shortage appear.

The difference between predictive and prescriptive is critical. Predictive analytics might warn that a shipment is likely to be delayed. Prescriptive analytics goes one step further. It recommends actions to avoid the delay, such as switching carriers, expediting via air freight, or shipping from an alternate warehouse.

Why the Data Foundation Matters

Prescriptive analytics is only as strong as the data it runs on. In many organizations, the raw material for decision-making, such as supplier data, inventory levels, part specifications, and compliance statuses, is scattered across ERP systems, procurement platforms, spreadsheets, and vendor portals.

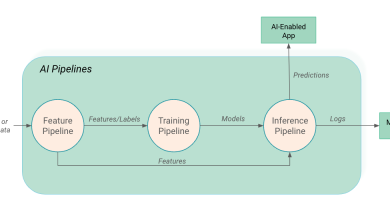

Without cleaning, harmonizing, and validating this information, even the most advanced recommendations can fall short or lead to missteps. Leading organizations are now using AI to standardize formats, fill in missing attributes, and resolve duplicates, ensuring that models operate from a single, accurate source of truth. When the foundation is solid, prescriptive systems can offer confident recommendations, and decision-makers can trust them.

From Recommendations to Automation

Early prescriptive tools were designed to support human decision-making. They gave operators the insights needed to choose the best course of action in real time. This alone enabled faster, more informed responses.

The next step pairs prescriptive analytics with automation. Once decision logic is proven and risk thresholds are set, the system can execute certain actions without human intervention:

- If a supplier’s lead times increase beyond a set limit, the system triggers an RFQ to approved alternates.

- If the inventory of a high-risk part drops below a threshold, it places an order with the most cost-effective qualified supplier.

- If a component is flagged as approaching end-of-life, the system automatically triggers an engineering review and generates a list of qualified substitutes. It then initiates early procurement to secure remaining stock before prices spike.

Automation does not replace human oversight. It manages routine tasks, allowing teams to focus on more complex and strategic decisions.

From Firefighting to Future-Proofing

This shift is more than a technology upgrade. It fundamentally changes how supply chains operate. Instead of reacting to problems as they arise, organizations can prevent or mitigate them before they escalate.

Planners, buyers, and logistics managers spend less time reconciling conflicting data and more time evaluating strategic options. Meetings shift from reviewing past failures to aligning on proactive strategies.

When disruptions occur, whether due to geopolitical events or climate-driven disasters, the organization is already in motion. As early warning signals are detected, contingency plans are triggered. This shortens recovery times, stabilizes costs, and protects customer commitments.

Scaling Prescriptive Intelligence

The value of prescriptive analytics grows as it is applied across more areas of the supply chain. Many organizations initially prioritize high-impact functions, such as sourcing and logistics, and then expand into demand forecasting, production scheduling, compliance management, and sustainability efforts.

Imagine a fully connected prescriptive system: demand forecasts update in real time; production schedules adjust based on material availability; logistics routes shift dynamically; compliance checks run continuously in the background.

The technology is already in use within leading organizations. The challenge now is scaling its capabilities, building trust in AI-driven recommendations, and establishing governance to ensure responsible automation.

A Competitive Imperative

In the past, supply chain excellence meant keeping costs low and moving goods efficiently under stable conditions. Today, stability is the exception. The advantage now lies in agility: anticipating change, adapting quickly, and recovering faster than competitors.

Prescriptive analytics is at the core of that agility. It enables organizations not only to understand their supply chains in real time, but to act on that insight with speed and precision. Those who adopt it will operate on a different time horizon than those still relying on backward-looking reports.

The lesson is clear: in the era of smart infrastructure, the shift from “what happened” to “here’s what we do next” will separate leaders from laggards. AI is the engine powering that transformation.