The swirling winds of AI are set to sweep through many facets of our lives, from healthcare to education, finance to transport and manufacturing. For businesses and workers, AI in its varied forms is already changing the job landscape and is a golden opportunity for reform and increased productivity.

Opportunities for improved output and new ways of working are no less apparent than in electronic engineering, with rigorous and trustworthy AI-based solutions rushing to the fore to mitigate talent shortages in technology and engineering. These market challenges continue to hamper businesses across multiple industries. One such industry – infrequently heard about in mainstream media headlines before this decade – is the semiconductor vertical, which has risen in global strategic importance.

Market Context

When Covid-19-enforced lockdowns and isolation kickstarted consumer demand surges for electronic products, such as televisions and computers, semiconductor chips became an even more indispensable and lucrative resource across the world, leading to fierce competition. The U.S. leads the world in developing and selling semiconductors, accounting for 45% to 50% of global billings. Manufacturing is the preserve of Asia, however, with Taiwan and Korea accounting for 83% of global processor chip production and 70% of memory chip output.

While chip production and global supply chains have always been difficult to predict, into 2023 tensions between the U.S. and China over chip manufacturing and supply have continued to grow, pointing to the political significance of the technology. Recently, the EU announced the European Chips Act, a $47BN package of public and private investments that aims to secure its supply chains and double the EU’s global market share in semiconductors from 10% to 20% by 2030.

Alongside the ever-present, long-term demand for electronic products, electronics engineers – who design schematics for them – now have crucial roles to play. And with pools of skilled labour running dry and becoming increasingly expensive, there has never been a greater need for AI to mitigate labour shortages and reduce the time it takes to design and create electronics.

Problem and Solution

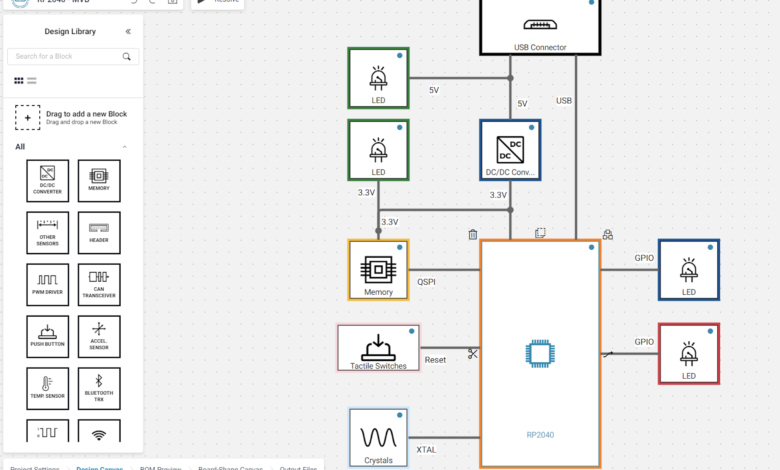

We are Munich-based deep tech company CELUS, and we’ve developed specialised AI-based software for engineers. The CELUS Engineering Platform provides a radical and now-essential tool for efficient and almost entirely automated designs of circuit boards, which reside within all electronic products. These contain hundreds or thousands of tiny hardware components, each with its own specifications, functionality, price and availability.

Until now, circuit boards have been designed involving many manual steps, relying on engineers’ experiential knowledge and research of necessary components, spending onerous hours trawling through datasheets that can contain up to 600 million components. Design cycles leading up to final design and component selections have always been complex, time-consuming, and iterative, with the risk of often unavoidable human error is always prevalent.

An individual component would need to be researched and paired with other specific components to make a design function, and yet engineers needed to manually discover if this component was available from both manufacturers and distributors. This was a huge time drain.

Now, AI can automate much of the previously manual process, leading to 90% reductions in design times and helping engineers navigate chip supply chain issues.

But what does CELUS actually offer, and what specific problem is solved? In short, the CELUS software system utilises AI to generate schematics, produce printed circuit board (PCB) floor plans, and develop a bill of materials (BOM). As for the problem, information on components and their availability have historically been digitally held by manufacturers and distributors but were shared with engineers as PDF datasheets, only to be transferred back into digital form by engineers themselves for their specific needs. A woefully inefficient transaction needlessly costs time.

Benefits of the CUBO(™) concept

One of CELUS’ unique solutions here is the CUBO(™) concept which smoothens the component data flows between distributors, manufacturers and engineers. CUBOs contain detailed information for component design, including electrical computer-aided design (ECAD) data, a BOM, port and connection information, and specifications for usage. The resulting designs are able to be repetitively reused by users – which is a common practice by engineers – with the CUBO functionality defined by select keywords and characteristics. In essence, the CUBO is almost a mini-circuit itself and operates to show how components interact with each other, allowing engineers to document their designs for better re-designs in the future.

Within minutes, all engineers – with varying skills from junior to senior level – can create circuit diagrams that work, with lists of appropriate parts and a base-level layout for a prototype in ECAD formats. This can be apportioned by team leaders who choose how to deploy their workers. The capabilities and productivity of whole teams of designers can skyrocket with CUBOs as every engineer gets access to maximum IP and design intent information. Data is not siloed into specific datasheets but is stored entirely and securely in the cloud, providing easy access to all.

CELUS and Labour Shortages

In yesteryear, knowledge of component specifications and well-functioning design schematics was held only by the most skilled workers with years of industry experience, but CELUS’ AI opens the door to mass productivity for engineers. The timing could not be better. The looming twin challenges of variable demand for electronics (and semiconductor chips) and restricted labour to produce the necessary supply are being met, or certainly mitigated, by AI.

Less experienced engineers can take up the mantle for previously dense and complex tasks (which still require some legwork). Skilled workers then have time to plan, innovate and execute new and creative designs, with project leaders factoring in this availability. Nonetheless, companies are still facing dramatic shortfalls in skilled worker numbers. A survey conducted by SD Worx showed that 59% of employers across the EU were experiencing a shortage of skilled workers. The U.S. is also looking to be short of 6 million technology workers.

CELUS has recently published its platform CELUS Open Space which is available to every design professional globally. It is currently available in beta mode but will be fully operational later this year. The CELUS Engineering Platform uses automation to improve the development speed of circuit design and increase workforce productivity. The data behind the platform, created in collaboration with component manufacturers, ensure high degrees of trust among customers. A dedicated content team also feeds the CELUS database to give engineers the baseline for their designs.

For the success of automation to continue – and to alleviate labour strains – AI must continue to be improved with an eye towards perfection. AI deployed in electronic engineering is still in its infancy. But in an age of global demand for skilled workers and specialised materials, the successful utilisation of machine learning will deliver unprecedented efficiency improvements to engineers and businesses.

To find out more from CELUS, reach out here: https://www.celus.io/en/contact