For companies with complex supply chains, 2020 has been a year of coming to terms with their blind spots, poor communication up and down the chain, and lack of resilience against challenges as they come up. Now, companies are dealing with how to recover from such historic supply chain shocks. It’s no question that COVID-19 has jumpstarted the need for organizations to achieve greater visibility into their supply chains.

To gain a greater understanding of the biggest challenges facing organizations this year, where product loss was happening in the supply chain (cold chains in particular), and how this disruption is affecting their bottom line, we partnered with Sapio Research to survey over 200 supply chain decision-makers across the pharmaceutical and food & beverage industries in the U.S.

Shockingly, pharma and food companies combined are losing an average of over $358 million every year because of product spoilage. Just as concerning is the fact that most of these companies are still relying on some form of manual processes for tracking.

Key Findings

Here is a sampling of some of the top findings in the report.

- 92% of total respondents said they could not 100% trust the product tracking data within their supply chains.

- 99% of respondents in the pharmaceutical industry used some type of manual process to get some visibility into their supply chains. 45% said they are using spreadsheets, while 35% said they are using pen and paper, and 27% are using alarm clocks.

- The top 5 supply challenges facing the pharmaceutical and food & beverage industries are:

- Product damage or spoilage (30%)

- Temperature excursions (25%)

- Unexpected delays (24%)

- Lost or misplaced inventory (21%)

- Compliance issues (20%)

- Most of the respondents in the pharmaceutical industry (87%) said they do not have 100% visibility into the condition of products in their supply chain during the last mile of delivery.

Pharma Industry is Severely Impacted

Companies in the pharmaceutical industry deal with a complex network of suppliers, manufacturers and logistics companies. These cold chain companies operate in a highly regulated, tightly controlled cold chain logistics system. To overcome these obstacles, pharmaceutical companies need a granular view of all products moving through the supply chain.

Incredibly, 99% of respondents in the pharmaceutical industry said they were using some sort of manual process to achieve supply chain visibility. Over half of the respondents (53%) in the pharmaceutical industry are not using supply chain software to achieve supply chain visibility.

According to the Sapio study, the top challenges for the pharmaceutical industry include:

- Product damage or spoilage (34%)

- Temperature excursions (28%)

- Unexpected delays (25%)

- Lost or misplaced inventory (21%)

- Compliance issues (20%)

Due to the lack of cold chain visibility, pharmaceutical companies reported a loss of $95 million on average in medical product spoilage. For companies that have 1,000 or more employees, the loss increased to $179 million. An additional 6% of pharmaceutical industry respondents claimed that lost $500 million – $1 billion due to product spoilage.

Food & Beverage Industry Also Challenged

Close to $71 million is lost every year due to fresh food spoilage that’s caused by cold chain failures. This number increased to $179 million for companies who have 1000 or more employees. 3% of food & beverage respondents claimed to have lost $1 billion or more annually from fresh food spoilage caused by cold chain failures.

One of the causes of supply chain blind spots could be tied to the outdated methods that organizations use to track shipments. 79% of food & beverage respondents reported using a manual process to achieve supply chain visibility. 44% of respondents still used spreadsheets, 43% still used pen and paper, and 27% used alarm clocks.

The top challenges for the food & beverage industry include:

- Product damage or spoilage (28%)

- Temperature excursions (28%)

- Unexpected delays (28%)

- Lost or misplaced inventory (19%)

- Compliance issues (19%) – tie

- Inaccurate data (19%) – tie

This lack of supply chain visibility has a dramatic impact on both food waste as well as on access to fresh foods for those who most need it.

Using AI/ML to Address Weak Points in Supply Chain

These failures in supply chain visibility can create a rippling effect across the entire organization, negatively affecting customer experience, product quality, regulation compliance, and inventory management.

The implications of these findings are significant given their impact on both operations and finances. Furthermore, given the changing expectations across the supply chain that require agility and speed in order to deliver as efficiently as possible, the stakes are only getting higher. Fortunately, the COVID-19 pandemic has acted as a springboard for modernization in the cold chain, putting the industry 18-24 months ahead of schedule on digital transformation.

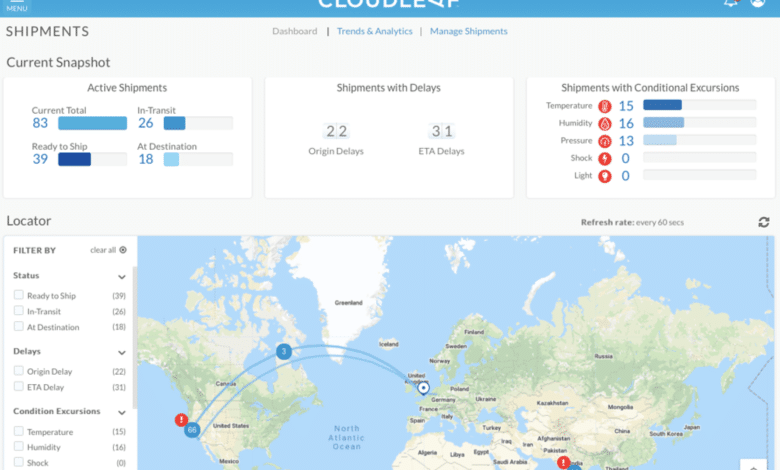

Organizations will look to newer data strategies beyond the current descriptive analytics. IoT sensors, digital twins, artificial intelligence (AI) and machine learning (ML) enabled technology will help process fragmented operational data sets across the organization, real time sensor data streams and contextual data from planes, trucks, customs, weather, traffic etc., to provide predictive and prescriptive analytics, which use historical data to predict failures and provide recommended actions before an incident occurs based on previous actions.

Leveraging AI/ML for prescriptive remediation can help avoid the millions of dollars companies are losing and deliver a better experience to their customers. By processing billions of real-time events every second, they provide companies with the greater context of insight around their products traveling through the supply chain, including real-time location data, traffic, weather, condition, utilization data, anomaly and risk detection.

Reliable end-to-end visibility is a capability that cannot be compromised in the highly regulated pharmaceutical and food and beverage industries. The ability to know everything that’s going on will soon be the defining factor for success in supply chain management, and those who don’t embrace real-time supply chain management will find it even more difficult to catch up to those who do with growing losses in finances and operations.

Those who do will be equipped to not only overcome their most costly gaps in visibility but take it a step further to revolutionize their supply chain monitoring to drive greater efficiency, productivity, better business outcomes and customer delight.