The operational gap AI must close

Modern produce operations generate torrents of information every day: field notes, canopy imagery, harvest and quality logs, refrigeration pings every few minutes, truck ETAs, and buyer specifications. Yet value still stalls behind pivot tables, siloed systems, and late night dashboard marathons. Information matters only when the right person can act on it in time, and in agriculture that window is measured in minutes, not hours. “AI for good” starts by closing the distance between data and the frontline decision that protects quality, reduces waste, and keeps promises to customers.

Natural interfaces, not new habits

Everyone talks about autonomous tractors and predictive crystal balls. Agriculture’s real edge is human: experienced people making fast, high-stakes calls under pressure. If AI demands new habits like extra logins, new screens, or unfamiliar workflows, it slows the very decisions it aims to improve. When the interface shows up as naturally as a quick conversation, a tap, or a photo, AI becomes a teammate rather than a chore. Picture a crew lead sending a voice note that asks, “Will Thursday’s romaine hold through Tuesday?” The response should not be a link to a dashboard. It should be a clear plan that quietly pulls from cooler temperature curves, field conditions, labor rosters, buyer tolerances, and truck routes, then recommends the next move with confidence.

Context is the catalyst

A chatbot alone will not do it. The missing layer is context. Represent crop blocks, pallets, orders, specifications, and sensors as live, connected entities that the system can reason over in real time. Ask a plain-language question and the answer anchors to the exact lot, cooler, retailer, and delivery window in play. When the model understands objects and their relationships, it can propose the safest next action, whether that means reroute, reprice, prioritize, or hold, and it can do so without spreadsheets or guesswork. Context is what turns a good demo into a decision you can stand behind.

Where “good” meets the P&L

Food loss drains roughly one trillion dollars a year from the global economy and accounts for eight to ten percent of greenhouse-gas emissions. A few points of improvement in harvest timing, grading, routing, and repricing deliver more benefit than the flashiest machine on the yard. “AI for good” is not a slogan. It is fewer rejected pallets, more product that stays in grade, and measurable climate gains.

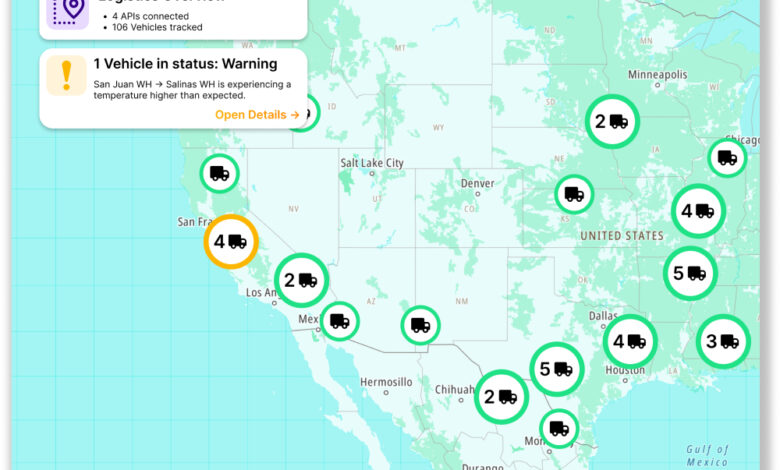

The benefits are practical and immediate. Frontline teams spend less time fighting exceptions when answers surface at the moment of choice. Clarity reduces rework and overtime and lowers stress across crews, dispatch, quality control, and buyers. Cold chain systems that watch for temperature excursions, traffic risk, and buyer windows can prevent quality drift and turn waste prevention into a daily habit. For regional growers, shippers, and retailers, scenario models that combine acreage, weather, and demand help teams rebalance faster as conditions shift. The value is not perfect foresight. It is faster re-forecasting every time the data changes.

A pragmatic playbook

Start where minutes matter. Do not chase abstract transformation. Pick decisions with visible loss or delay, such as harvest go or no go, lot grading, load consolidation, and reroute versus reprice. Prove you can save a pallet today.

Make the interface the product. Treat voice, chat, and image flows as first-class features. The best model will not help if the interaction is clumsy. If people cannot use it with gloves on, it is not ready.

Build the context layer early. Unite the things your operation runs on, including blocks, pallets, orders, specifications, and sensors, so every question resolves to the right object graph. This prevents brittle lookups and the slow data lake drift that erodes trust.

Design for the edge. Connectivity blinks. Support offline capture and lightweight on-device inference so work continues when the signal does not. Sync later; decide now.

Measure what operations feel. Track minutes saved, waste avoided, service level consistency, shelf life accuracy, and margin contribution, not only model accuracy. Scorecards should mirror how farms, sheds, and buyers already run the business.

Build governance in. Provide explanations, show provenance, log decisions, and make overrides safe. People adopt what they can question and verify.

Co-create with the field. Pair agronomy and quality leaders with data teams. Edge cases and local knowledge turn a promising tool into daily muscle memory. Start small, iterate quickly, and codify what works.

What gets in the way

Adoption debt appears when tools ask people to stop and learn before they can move. Solve a real pain in week one and teach as you go. Data fragmentation across ERPs, WMSs, and spreadsheets creates competing versions of truth. A thin semantic layer that federates sources usually beats a big-bang migration. Over-automation introduces new risks. Use automation where the environment is stable and safe, and keep recommendations and explanations in the loop elsewhere. Guard against vendor lock-in by favoring open interfaces and portable data models, because both operations and climate will keep changing.

The human dividend

“AI for good” is about people. In agriculture, that means honoring generational expertise while removing friction that steals time and options. Natural interfaces let experience travel faster within a crew, across shifts, and between partners, so fewer decisions are made in the dark. Contextual AI turns that wisdom into consistent action at scale. The reward is financial, and it is also dignity in work done well.

The horizon

The first ag-tech wave helped machines sense fields and facilities. The second taught systems to listen in natural language. The wave arriving now is understanding, a blend of conversation and context that places the right answer exactly where work happens. When that alignment lands, agriculture’s century-old craft fuses with AI’s stamina. The result is fresher food, stronger margins, and supply chains that finally move at the speed of the people who power them. That is AI for good, and it is good business.