Manufacturers investing in 5-axis CNC machining are often seeking unparalleled efficiency and the ability to produce complex geometries, yet many encounter a stark reality:challenges such as complex programming, hidden collision risks, and accuracy loss from multiple setups can erode the technology’s promised benefits — even leading to costly rework. These issues stem largely from traditional reactive methods, which rely heavily on operator experience and post-process inspection, lacking the proactive, data-driven intelligence required to fully leverage 5-axis capabilities.

To overcome these limitations, manufacturers are increasingly turning to AI-driven strategies that fundamentally transform the 5-axis workflow. By integrating predictive analytics, real-time vision systems, and intelligent path optimization, it becomes possible to shift from troubleshooting problems to preventing them—unlocking new levels of reliability, precision, and productivity.

How Can Predictive Maintenance Transform Multi-Axis Machining Uptime and Tool Life?

Unplanned downtime is a significant profit killer in capital-intensive 5-axis machining. Traditional maintenance schedules, based on time or usage, are inherently inefficient—either performing unnecessary maintenance or failing to prevent a breakdown.

1. From Reactive to Proactive Asset Management

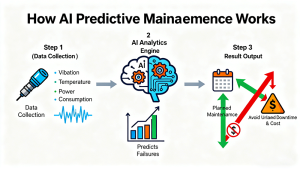

Visual breakdown of how AI analytics convert machine data into actionable insights, preventing costly downtime before it happens.

AI-powered predictive maintenance uses sensors to continuously monitor critical parameters such as spindle vibration, temperature, and power consumption. Machine learning algorithms analyze this data in real-time to detect subtle anomalies that precede failures.

2. Maximizing Investment Return

By accurately forecasting the remaining useful life of components like the spindle and bearings, maintenance can be scheduled during planned downtime. This approach maximizes tool life, eliminates unexpected stoppages, and ensures that your high-value 5-axis equipment delivers maximum return on investment.

3. Authority Reference

The National Institute of Standards and Technology (NIST) Smart Manufacturing Systems program highlights predictive maintenance as a cornerstone for achieving manufacturing resilience and operational efficiency.

What Role Does Computer Vision Play in Achieving Real-Time Quality Control for Complex Geometries?

Verifying the quality of complex, contoured parts produced on 5-axis machines often requires slow, subjective, and costly manual inspection. This creates a bottleneck and risks defective parts moving down the supply chain.

- The 100% Inspection Paradigm: AI-driven computer vision systems use high-resolution cameras and sophisticated algorithms to perform 100%inspection of every part. They can measure intricate features, surface finishes, and geometric tolerances with micron-level accuracy at production speeds.

- Closing the Loop on Quality: The true power lies in creating a closed-loop system. If a deviation is detected, the system can automatically flag the part or even signal the CNC machine to make compensatory adjustments for the next component. The application of this technology in real-world scenarios, such as the 5-axis machining of complex aluminum aerospace brackets detailed in this case study, demonstrates its profound impact. This capability is especially critical for industries like aerospace, where adherence to International Aerospace Quality Group (IAQG) standards is paramount, and medical, where quality is non-negotiable.

How Does AI-Driven Path Optimization Enhance Efficiency and Safety in 5-Axis Machining?

The freedom of 5-axis movement introduces complexity in programming optimal toolpaths that are both efficient and collision-free. Traditional CAM software relies heavily on programmer skill and experience.

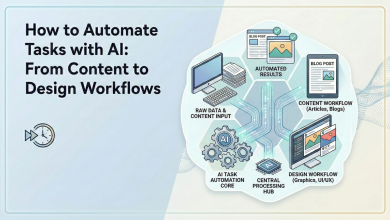

- Simulating Perfection Before Cutting: AI-driven path optimization software uses advanced simulation and machine learning to analyze and refine toolpaths. It can automatically adjust feed rates, cutting depths, and approach angles to maintain optimal cutting conditions, while simultaneously simulating the entire process to eliminate any possibility of tool-holder collisions with the workpiece or fixtures.

- A Safer, Faster Path to Production: This not only slashes programming time and enhances material removal rates but also acts as a critical safety net. By virtually eliminating collision risks, manufacturers can protect their machinery from catastrophic damage and empower programmers to explore more efficient strategies with confidence.

- Authority Reference: Research published on Science Direct on the application of machine learning in CNC machining services confirms that AI-based optimization significantly reduces machining time and improves surface quality compared to traditional methods.

When Should Manufacturers Choose 5-Axis Over 3-Axis Machining?An AI-Powered Decision Framework

The choice between 3-axis and 5-axis machining isn’t always straightforward. Selecting the wrong technology can lead to either excessive costs or inadequate capabilities. For a comprehensive framework on making this critical decision based on part geometry, batch size, and precision requirements — which is fundamental to planning an effective quality control strategy—we detail this in our complete guide: A Comprehensive Guide for Selecting 3-Axis and 5-Axis CNC Machining

1. The Complexity Versus Cost Equation

A data-driven decision framework analyzes key factors such as part geometry(e. g. , deep cavities, undercuts, compound curves), batch size, and tolerance requirements. For components with complex contours, 5-axis machining’s ability to complete a part in a single setup often outweighs the higher initial investment by eliminating errors from multiple re-fixturing.

2. Quantifying the Value of a Single Setup

The decision becomes clear when considering the cumulative cost of secondary operations, fixture design, and potential accuracy loss in 3-axis production. For complex parts, the“single-setup”advantage of 5-axis machining is not just a convenience but a critical determinant of final part quality and total cost.

Looking to Maximize Your 5-Axis Machining Investment?

Choosing the right technology is the first step. The next is unlocking its full potential. While 5-axis CNC machining offers unparalleled capabilities for complex parts, challenges like complex programming, collision risks, and ensuring consistent quality can impact your ROI. Discover how AI-driven strategies are transforming 5-axis operations—from predictive maintenance to real-time quality control—in our latest insight: 3 AI-Driven Strategies to Unlock the Full Potential of Your 5-Axis CNC Machining.

Conclusion

Integrating AI into 5-axis CNC machining is no longer a speculative future but a practical pathway to achieving a decisive competitive edge. The strategies outlined here—predictive maintenance, real-time quality control, and intelligent path optimization—empower manufacturers to transcend traditional limitations. This evolution moves the industry from reacting to problems to a state of predictive optimization, ensuring that investments in advanced manufacturing technology yield their full potential in precision, efficiency, and reliability.

FAQs

Q: What is the fundamental difference between 3-axis and 5-axis CNC machining?

A: 3-axis machining provides movement along three linear axes(X, Y, Z)and is suitable for simpler parts. 5-axis machining adds two rotational axes, allowing the cutting tool to approach the workpiece from virtually any direction in a single setup.

Q: Can AI really help prevent tool collision in 5-axis machining?

A: Yes, absolutely. Advanced AI-powered CAM software performs a virtual simulation of the entire machining process. It calculates the precise movements of the tool, holder, workpiece, and fixtures to identify and eliminate potential collisions before any G-code is ever sent to the machine, drastically enhancing safety.

Q: Is 5-axis machining only beneficial for high-volume production?

A: Not necessarily. While it excels in high-volume efficiency, its”single-setup”capability is equally valuable for prototypes and low-volume batches. It ensures that the prototype accurately reflects the design intent by eliminating errors introduced from repeated re-clamping, which is critical for validation.

Q: How does predictive maintenance in CNC machining work?

A: Sensors on the machine collect real-time data on parameters like vibration, temperature, and power consumption. AI algorithms analyze this data to detect subtle patterns and anomalies that indicate wear or an impending failure. This allows maintenance to be scheduled proactively, before an unplanned breakdown occurs.

Q: What are the first steps to integrating AI into my existing manufacturing process?

A: A strategic approach is to start with a pilot project focused on a high-impact area, such as implementing computer vision for quality checks on a critical component. Success in a contained pilot builds confidence, demonstrates ROI, and provides a blueprint for broader integration across the operation.