Introduction

Stainless steel thread turning remains one of the most demanding operations in CNC machining. Machinists often grapple with unpredictable tool wear, work hardening of the material, and minute variations that lead to out-of-spec threads, resulting in scrapped parts, costly rework, and project delays. The core issue lies in the limitations of traditional methods, which lack the real-time data and adaptive intelligence to proactively manage these complex dynamics.

This article presents five research-driven, AI-powered strategies that are transforming this critical process. By integrating smart technologies, manufacturers can move from reactive problem-solving to predictive optimization, achieving unprecedented levels of precision, efficiency, and cost-effectiveness in stainless steel thread production.

How Can AI-Powered Manufacturing Optimize Stainless Steel Thread Turning Parameters?

The foundation of precise thread turning lies in the perfect synergy of cutting speed, feed rate, and depth of cut. However, these parameters are not static; they need to adapt to material lot variations, tool condition, and even ambient temperature.

The Challenge of Static Parameters in a Dynamic Environment

Applying a single set of”optimal”parameters from a handbook is often insufficient. Stainless steel’s tendency to work-harden means that as a tool wears, cutting forces and temperatures can rise, accelerating wear and degrading thread surface finish in a negative feedback loop.

AI as the Adaptive Brain

AI and machine learning algorithms can analyze real-time sensor data (e. g. , vibration, acoustic emissions, power consumption) to detect subtle patterns indicative of optimal or sub-optimal cutting conditions. This allows the system to dynamically adjust parameters on the fly, maintaining a stable, efficient cutting process throughout the tool’s life.

Authority Reference: The National Institute of Standards and Technology (NIST) Smart Manufacturing Systems program emphasizes the critical role of real-time process adaptation for achieving manufacturing resilience.

Ensuring Consistency Through Systematized Expertise

Implementing such a system requires a robust framework to ensure reliability. For instance, a manufacturing partner with an ISO 9001: 2015 certified quality management system provides the structured data foundation necessary to train and validate these AI models, ensuring that the adaptive intelligence delivers consistent, high-quality results batch after batch.

H2: What Role Does Predictive Maintenance Play in Extending Tool Life for Thread Turning Operations?

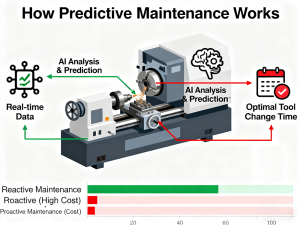

Figure 2: The predictive maintenance workflow maximizes tool life and prevents unexpected downtime, slashing costs effectively.

Tool failure during a thread turning operation doesn’t just ruin a part; it can damage the workpiece and the machine spindle. Traditional time-based tool changes are either wasteful(replacing a tool with life remaining)or risky (a tool failing prematurely).

- The High Cost of Unplanned Tool Failure: A broken tap or insert in the middle of a deep, blind hole can lead to hours of costly rework or even a scrapped component, blowing out production costs and timelines.

- From Scheduled to Predictive Replacement: Predictive maintenance uses sensors to monitor tool health directly. By analyzing trends in cutting force or vibration, the AI can accurately forecast the remaining useful life of a specific tool, alerting the machinist to change it just before it reaches the end of its optimal life. This maximizes tool utilization and eliminates unplanned downtime.

- A Partner with a Foresight Capability: A manufacturer with a mature predictive maintenance program, underpinned by standards like IATF 16949, brings a level of foresight to production planning. This capability ensures that tooling is managed as a strategic asset, directly contributing to on-time delivery and cost predictability.

| Comparison Aspect | Traditional Time-Based Tool Change | AI-Predictive Tool Change |

|---|---|---|

| Decision Basis | Fixed schedule or production count, ignoring actual tool condition. | Real-time sensor data analysis to forecast remaining tool life. |

| Change Timing | Too early(tool is still usable=waste)or too late(tool is worn=part defects). | At the optimal point, just before performance drops. |

| Primary Outcome | High Cost: Tool waste+Quality risk | High Efficiency: Maximized tool use+Guaranteed quality |

| Visual Concept | ×Waste Zone(Too Early)→RiskZone(Too Late) | √Optimized Zone(Precise Change) |

How Can Digital Twin Technology Simulate and Perfect Thread Machining Processes?

What if you could test and perfect a threading program without wasting a single piece of stainless steel?Digital twin technology makes this possible.

- Virtual Validation Before Physical Cutting: A digital twin is a dynamic, virtual replica of your physical machining process. It simulates the entire operation — from CNC code and toolpath to material behavior and machine kinematics — allowing engineers to identify potential issues like tool collision, chatter, or even minor dimensional inaccuracies before any physical setup.

- Slashing Setup Time and First-Article Scrap: By perfecting the process in the digital realm, machinists can drastically reduce machine setup time and achieve a right-first-time outcome on the very first part. This is particularly valuable for complex, high-value components where the cost of scrap is exceptionally high.

- Real-World Application: For example, when simulating the machining of a critical stainless steel valve body, our engineers used a digital twin to identify a potential vibration during the final threading pass. They adjusted the tool support and cutting parameters in the simulation, eliminating the problem before it could occur on the shop floor, saving an estimated 15 hours of troubleshooting and rework.

Why Is AI for Quality Control Essential for Ensuring Thread Accuracy in High-Volume Production?

Manual inspection of threads is slow, subjective, and prone to human error, especially in high-volume production. AI-powered vision systems redefine quality assurance.

100%Inspection at Production Speeds

Advanced camera systems integrated with AI algorithms can perform 100%inspection of every thread produced, measuring key parameters like pitch, major diameter, and flank angles with micron-level accuracy in milliseconds.

Closed-Loop Feedback for Instant Correction

The true power of AI quality control lies in its ability to create a closed-loop system. If a deviation is detected, the system can automatically signal the CNC machine to make a compensatory adjustment for the next part, preventing the production of a batch of non-conforming components.

We have explored the transformative impact of this technology in greater detail in our guide on AI in Precision Machining. This resource explains how real-time data feedback is creating a new paradigm of zero-defect manufacturing. For a comprehensive foundation in the core principles and techniques, including traditional best practices that these AI strategies enhance, we recommend reading the ultimate guide to CNC stainless steel thread turning.

How Do Smart Manufacturing Principles Transform Stainless Thread Production Efficiency?

Individually, these AI strategies are powerful. But their full potential is unleashed when integrated under the umbrella of Smart Manufacturing and Industry 4. 0.

- The Power of Integration: A truly smart factory connects AI parameter optimization, predictive maintenance, digital twins, and AI quality control on a unified data platform. This creates a holistic view of the production process, where insights from one area inform actions in another.

- Building a Sustainable Competitive Advantage: This integrated approach leads to unparalleled efficiency gains: less waste, lower energy consumption, and optimized resource use. A commitment to this philosophy, reflected in certifications like ISO 14001, demonstrates that peak efficiency and sustainability go hand-in-hand. For manufacturers looking to build a future-proof operation, exploring a partner’s full spectrum of capabilities — from advanced prototyping to high-volume production — is crucial for seamless technology integration.

Conclusion

Mastering stainless steel thread turning is no longer solely about the skill of the machinist or the quality of the tooling. It’s about leveraging intelligent technologies to gain a decisive edge. The AI-driven strategies outlined here — adaptive parameters, predictive maintenance, digital twins, automated quality control, and systemic integration — empower manufacturers to transition from fighting costly rework to achieving predictable, premium-quality outcomes. Adopting these approaches is not merely an upgrade; it’s a strategic move toward leading the next generation of precision manufacturing.

FAQs

Q1: What is the single biggest challenge in stainless steel thread turning and how can it be overcome?

A1: The biggest challenge is work hardening, causing rapid tool wear and poor surface finish. Solution: Use premium coated tools (e. g. , TiAlN), ensure ample coolant, and employ AI-optimized cutting parameters to maintain stable forces and avoid creating a hardened layer.

Q2: How do I select the right tooling for stainless steel thread turning?

A2: Base selection on material grade, thread type, and volume. Key factors: substrate(prefer micro-grain carbide), coating(e. g. , TiAlN), and geometry. For high volume, use predictive

maintenance to monitor wear for scientific tool change scheduling.

Q3: How does Digital Twin technology help reduce setup time in thread machining?

A3: A Digital Twin simulates the process virtually. It allows testing CNC programs, fixtures, and toolpaths beforehand, identifying collisions or issues early. This cuts on-machine debugging and inspection time, potentially reducing setup by 50%.

Q4: What are the advantages of AI Quality Control over manual inspection for threads?

A4: AI offers superior speed, consistency, and accuracy. It enables 100%inspection at production speed, detecting tiny deviations in pitch or form with micron-level repeatability, eliminating human error and enabling real-time corrections.

Q5: Will implementing these AI strategies significantly increase production costs?

A5: There’s an initial investment, but evaluate based on total cost of ownership. By reducing scrap, extending tool life, and maximizing uptime, AI typically delivers a strong ROI. Preventing a single spindle crash via predictive maintenance can save more than the system’s cost.